With the development of packing industry, manufacturers are always looking for efficient packaging systems and cost-effective packaging solutions. In this ultimate FAQ guide, we’ll cover everything you need to know about 4 side seal pouch packing machines, including the most frequently asked questions people search on Google.

What is 4 side seal pouch packing machine?

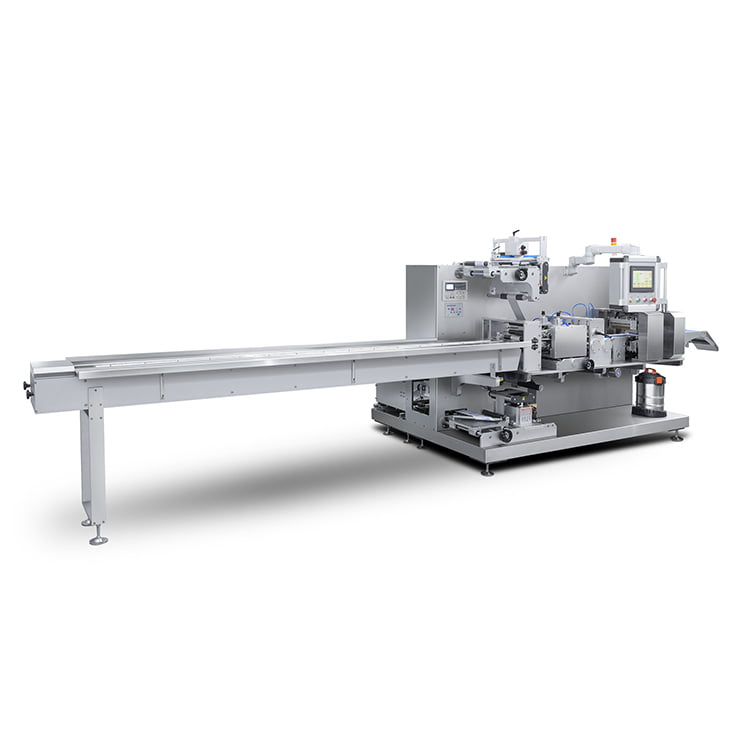

A 4 side seal pouch packing machine is used to make pouches by sealing all four sides of a flexible film. It can package powders, granules, liquids, and solids. The pouches it creates protect the products inside from moisture, light, and oxygen. This helps to keep the products fresh and in good condition for longer.At the same time, some necessary options such as coding machines, conveyors and metal detectors also play an important role in the entire packaging system

During production, Sachet and big size pouch you can choose.The pouch it made protects your product from moisture, light and oxygen. This helps keep the product fresh and in good condition for longer, which then leads to a high return on investment.

How does 4 side seal pouch packing machine work?

The 4 side seal pouch packing machine operates in a series of steps:

- Film unwinding: A roll of film is put on the machine, and the film is unwound and guided through it.

Notice:Ensure that the film roll is properly loaded onto the machine, with the correct alignment and tension. Monitor the film unwinding process to prevent any issues such as film tearing or misalignment. - Printing and coding:can be added to the machine to print information, barcodes, or expiry dates on the film.

Notice: Set up the printing and coding system according to the required information, ensuring the accuracy of the printed content. Regularly check and maintain the printing system to ensure clear and legible prints. - Forming: The film is folded and formed into a pouch shape using forming collars or plates.

Notice:Verify that the forming collars or plates are properly installed and adjusted for the desired pouch size and shape. Monitor the forming process to prevent any issues such as uneven forming or pouch deformities. - Filling: The product is dosed into the formed pouch using a filling system, such as an auger filler for powders or a piston filler for liquids.

Notice:Calibrate and configure the filling system according to the specific product and desired fill weight. Regularly check and clean the filling system to prevent any contamination or inaccurate dosing. - Sealing:The machine applies heat and pressure to the edges of the pouch, sealing all four sides to create an airtight seal.

Notice: Monitor the sealing process to ensure consistent heat and pressure application for a secure and reliable seal. Check for any signs of seal defects, such as incomplete seals or leakage. - Cutting: The sealed pouches are cut into individual units and discharged from the machine.

Notice:Verify that the cutting mechanism is properly aligned and functioning correctly to ensure clean and accurate cuts. Regularly inspect and maintain the cutting system to prevent any issues such as jagged edges or improper cutting.

What are the Benefits of using 4 side seal packing machine?

There are several benefits to using a 4 side seal pouch packing machine, including:

- Product protection: The sealed pouches provide excellent barriers against external factors, ensuring the packaged products remain fresh and protected.

- Adaptability: These machines can handle many different products and packaging materials, making them suitable for various industries and uses.

- Efficiency: Automated pouch packing machines make lots of pouches quickly, saving time and money on labor.

- Customization: Many 4 side seal pouch packing machines offer options for customization, such as zippers or spouts on the pouches

What materials can be used for 4 side seal pouches?

The most common materials used for 4 side seal pouches include:

- Polyethylene (PE): A versatile and cost-effective material that provides good moisture, gas, and odor barriers.

- Polypropylene (PP): Offers excellent clarity, heat resistance, and barrier properties, making it suitable for high-temperature applications.

- Polyester (PET): Polyester, also known as PET, is a durable material. It is commonly used for packaging food and medicine. This is because it effectively prevents water, gas, and odors from entering.

- Aluminum Foil: Provides the best barrier against light, moisture, and oxygen, making it ideal for products sensitive to these elements.

These materials can be used alone or in combination as multi-layer structures to achieve specific packaging requirements.

What types of products can be packaged using 4 side seal pouch packing machine?

A 4 side seal pouch packing machine is suitable for packaging a wide range of products, including:

- Food products: Snacks, spices, coffee, tea, sugar, salt, condiments, and more.

- Pharmaceutical products: Tablets, capsules, powders, and ointments.

- Cosmetic and personal care products: Creams, lotions, shampoos, and soaps.

- Chemical products: Detergents, pesticides, and fertilizers.

- Other products: Small hardware items, toys, and promotional materials.

How Do I Choose the Right 4 Side Seal Pouch Packing Machine for My Business?

When selecting a 4 side seal pouch packing machine, consider the following factors:

- Product Type: Determine the type of product you’ll be packaging, as the machine’s specifications should match your specific needs.

- Production Capacity: Consider the production capacity you require. Machines come in various output ranges, so choose one that meets your desired output.

- Budget: Analyze your budget and choose a machine within your price range.

- Ease of Use: Opt for a machine with user-friendly controls and interfaces.

- After-sales Support: Select a manufacturer that offers reliable after-sales support, including training, maintenance, and spare parts availability.

How Do I Maintain High Speed 4 Side Seal Pouch Packing Machine?

Regular maintenance is crucial for the optimal performance and longevity of your machine. Follow these steps:

- Cleaning: Clean the machine regularly to remove product residue and dust.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations.

- Inspection: Inspect the machine for any signs of wear and tear, and replace worn-out parts as needed.

- Scheduled Maintenance: Adhere to the manufacturer’s suggested maintenance schedule.

How much does 4 side pouch packing sealing machine price?

The price of a 4 side seal pouch packing machine can vary greatly. This variation is based on factors such as its capacity, speed, automation level, and additional features.Prices can range from $10,000 for a basic model to over $100,000 for a high-end, fully automated machine. It’s essential to carefully consider your production requirements and budget when selecting a machine to ensure it meets your needs.

How to troubleshoot common issues with a 4 side seal bag packaging machine?

- Check the bag stock. Make sure the bags are the correct size, material, and crimped properly for the machine. Damaged or misaligned bags can cause issues.

- Check the seal bars and cutters. Make sure they are clean, undamaged, and properly heated. Dirty or damaged seal bars will produce poor seals.

- Check the film tension. The bag material needs to be fed smoothly and consistently into the machine. Adjust the film tension if needed.

- Check film alignment. The bag material needs to be centered and aligned properly with the seal bars. Adjust the film guides if the bag is misaligned.

- Check for jams. Material can jam in the seal bars, cutters or film feed system. Clear any jams and identify the cause.

- Check the air supply. The machine requires clean, dry compressed air to operate properly. Check the air pressure and filters.

- Check the timers and sensors. Verify all timers and sensors for the seal bars, cutters and film feed are working correctly.

- Check for worn parts. Parts like O-rings, belts, and gears can wear out over time which affects performance. Replace any worn parts.

Conclusion

4 side seal pouch packing machines offer numerous benefits for businesses across various industries. This ultimate FAQ guide has provided insights into the workings and advantages of these machines, helping you make an informed decision when selecting the right packaging solution for your needs. By considering the factors mentioned above, you can invest in a 4 side seal pouch packing machine that will contribute to the success and growth of your business.