When people start looking for reliable packaging machine manufacturers, they will search Google or other websites first. Everyone knows that owning an automatic pouch bagging machine is a wonderful thing. Not only improve production efficiency, but also make more profit. So how to find a packaging machine manufacturers that is just for your needs?

This article will introduce tips and tricks for finding a reputable supplier. Please follow this and keep them in mind while searching and sourcing from China. Let’s start exploring.

Have you met Common problems with packaging machine manufacturing companies?

Expensive European Machinery

Acquiring European machinery can mean higher costs for your packaging machine. However European machinery can also offer leading-edge technology and better quality.

Low-quality Machines From Asia

When purchasing Asian machinery, quality control can be a major concern. Choose a trusted supplier to avoid costly equipment failure. However, Asian machinery can offer an excellent price-to-specification ratio if you choose the right equipment. Time cost should be added.

Delivery, Installation and Commissioning

Equipment/machinery delivery and installation can take longer than expected. Plan accordingly to avoid costly delays in your production deadlines.

Commission work can be time-consuming and requires experienced technicians who can skillfully troubleshoot and debug the machinery.

Why Do Customers Prefer To Buy Packaging Machine From China?

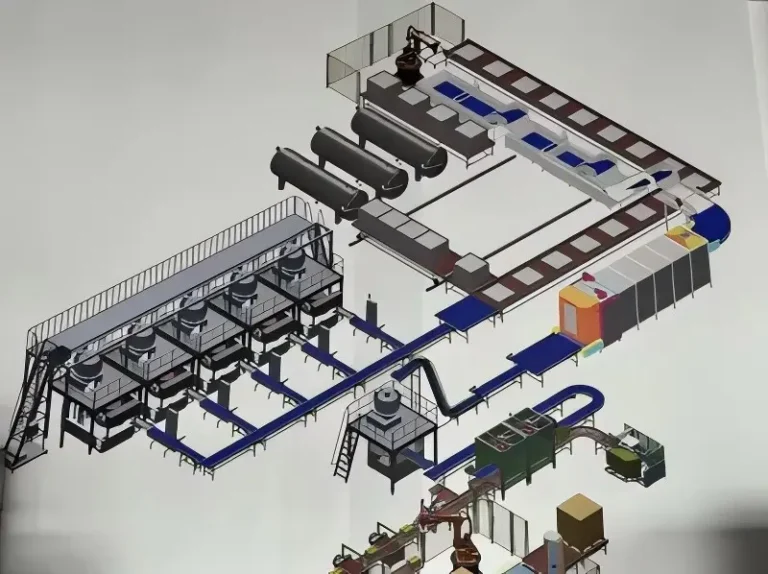

Compared to other countries, China has been a big manufacturing country for several years. The abundant supply chain allows for the production of diverse types of packaging machinery, such as filling machines, sealing machines, labelling machines, capping machines etc.

One of the main reasons why you may want to choose Chinese machine manufacture is the low costs of production. Companies in China have found a way to manufacture the best quality pouch-packing machines at more convenient prices than Europe or the USA.

The Chinese manufacturing industry thrives over the fact that it has developed an efficient business ecosystem. The ecosystem comprises of suppliers, distributors, packaging companies, shippers, governmental agencies, sourcing, and quality control companies. These networks collaborate to make sure that the process is efficient. This helps to foster the performance of the business in China as a whole

The Way To Find A Reliable Packaging Machine Supplier in China

From Internet

Because of Covid 19, people are adapting to search for suppliers through Google. However, you should focus on a wide range of options and pick out cereal manufacturers. Also, social media is a good place too.

Trade show

If you are ready to start a new business or grow a business, attending a trade show is a good idea. It is the best place to meet some incredible manufacturers and suppliers. Of course, better to visit the trade show in China once you decide to buy a Chinese machine.

A Brand Agent

Big companies have distributors all over the world. It is not a bad idea to buy a packaging machine from the brand distributor if you do not trust the internet result or cannot take a trip to China to attend the fairs and trade shows.

Sharing your needs and product details is the first step. Then they will help match you with the best suitable model. Language barriers do not exist. And you can get prompt responses and learn more knowledge to make a decision.

From Friends or Peers Familiar With the Industry

Glad to hear that you can reach out to those near who may have experience in the packaging machine field. Ask your peers and colleagues if they have some recommendations for you.So you can gain insight into which companies are reliable and trustworthy.

Things To DO and Consider Once You Find Pouch Bagging Machine Suppliers

Check the reputation of the packaging machine supplier

To ensure you’re dealing with a reliable supplier, it’s important to check online reviews and customer feedback. Look for reviews on social media, review sites, and other platforms to see what other customers think about the supplier.

Consider the location

Choosing a supplier located in areas where packaging machine industry professionals gather and in developed cities can be more convenient.

Compare product quality and price

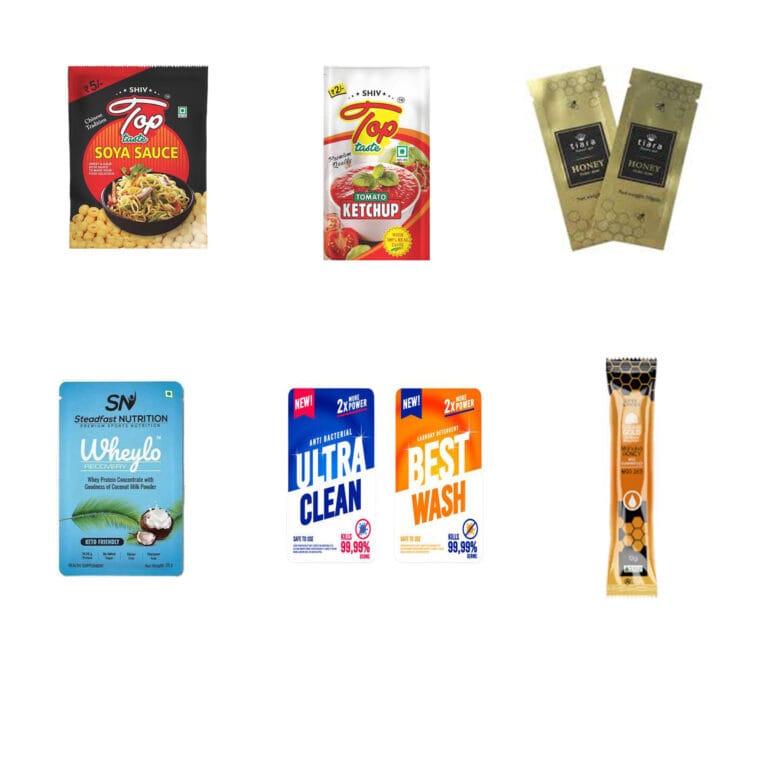

Research and compare the quality and price of products offered by different suppliers. Ask about materials, specifications, customization options, warranties, and other details to make sure you’re getting the best value for your money.

Evaluate customer service

Good customer service means quick response times and helpful staff who are willing to answer your questions.

Ask for samples

Request the supplier to provide sample bags produced by their packaging machines. This will allow you to evaluate the quality and ensure they meet your standards. It’s a great way to make sure the packing machine meets your needs

Ask for references

Inquire if the supplier can provide references from their customers, preferably those who have purchased similar products. Talking with these customers can give you an idea of the supplier’s product quality and services.

How To Ensure The Safety Of Your Cooperation With Packaging Machine Suppliers?

After you have conducted your research and identified a potential manufacturing company to work with, the next best thing is to verify the company. That way, you can make sure that it is trustworthy.

The following tips should come in handy for the verification process;

- Read through the company background and basic details (business license, ownership status, physical location, customer references, certification, and profile). Make sure to read through the company website keenly and entirely.

- Assess the product samples and qualities

- Organize a video call with the manager and the sales rep of the company where you get to ask through-through questions. This should help with verifying the professionalism of the company and its senior staff. Treat this call like a negotiation.

- Organize a visit to the factory for inspection

Tips and Tricks for communicating with Chinese suppliers

Language barriers between suppliers and customers are often a concern for customers. This obstacle is not a hindrance. This is because most of the overseas sales of Chinese manufacturers and suppliers are English-speaking. The person is proficient in English so communication is simple. There are several ways to communicate with Chinese suppliers. Most of these platforms are online.

1) Whatsapp

The most common method of communication is through the WhatsApp application. Accessing apps through Android, IOS and various Windows devices can be easier. It also provides a web platform.

2) Skype and Zoom

Also, apps like Skype and Zoom are solid alternatives. These platforms, like Whatsapp and Mailbox, rely on an internet connection to communicate.

3) Telephone

Calling is a more expensive option. But it’s the fastest way to contact Chinese manufacturers.

4) E-Mail

Finally, a mailbox in the form of email is a trusted form of communication. Note that time to reply to emails is often the slowest way to communicate. This can be frustrating if the information being shared is time-sensitive to the process.

5) e-commerce site

Some vendors are also based on the messaging section built into e-commerce sites. From personal experience, delegated communication agents respond quickly. The agents are also very knowledgeable and offer different quotes and machine qualities.

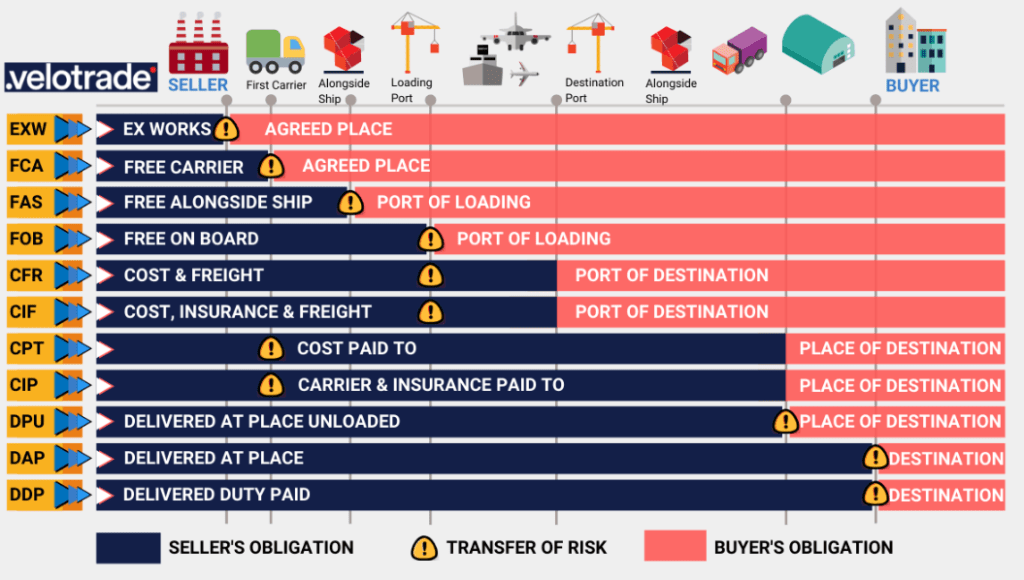

International Trade Terms

International trade is the current ratio of export prices to import prices. These shipping terms are also known as INCOTERMS. These determine how much the supplier will offer you after discussing the terms of trade. When choosing an incoterm, be aware that the most expensive step is domestic shipping. And the shipping process for imports from China. At this point, it is wise to negotiate from an informed perspective. This will get the best price for your machine. Below are 5 of the most common Incoterms.

1) EXW (EX -work)

When you use this quote on a product price, it quotes the original product price. Disturbingly, these terms of trade are where most of the processing is done by the customer. This price is easy to compare among the various manufacturers you care about. This requires you to find a freight forwarder to go to the supplier’s warehouse to pick up the machine. Another option is to use a courier service to receive the product. This option will allow offers on ECW terms. This is because, in China, courier services can pick up packages. Then from the supplier’s workhouse, delivered to you faster than other shipping methods. The burden of liability and shipping responsibility falls on the customer. This is when the machine is ready to be shipped.

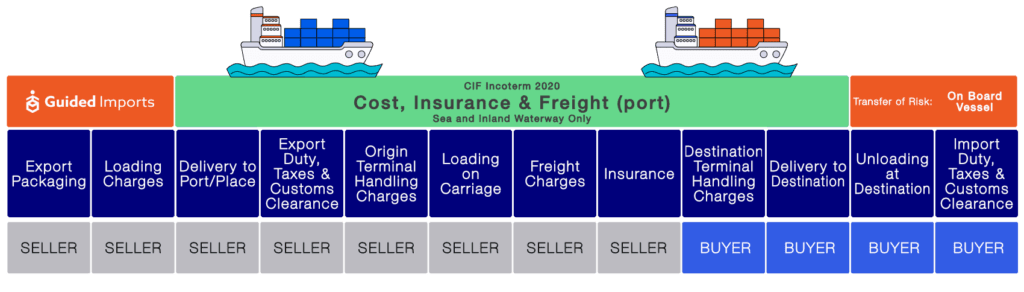

2) CIF (cost plus shipping)

Cost, insurance, and shipping are other common ways of quoting products. The price includes the cost of the goods, shipping, and insurance to a country. It is important to note that this insurance is partial as far as the insurance factor is concerned. It only covers the case of lost goods. This insurance does not cover damage to the goods. It also does not include damaged packaging of the goods. Any damage in transit is not included. Quotes in CIF terms can serve as import blueprints without freight forwarders. It allows you to find local companies and customs brokers. The goods are then shipped and you are notified of any further logistics in the process.

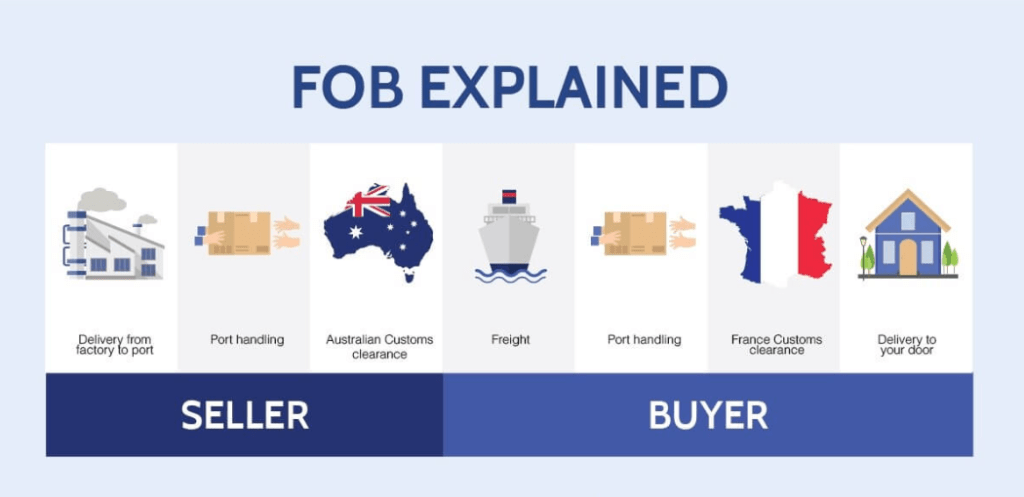

3) FOB

The supplier will give you a quotation based on the shipment of the goods to the sea vessel. in a seaport of your choice. The same goes for the plane that delivers the cargo to the airport of your choice. If you don’t know a marine port or airport, your supplier can help. Ask the supplier for the nearest port location and ask the supplier to quote you. In this case, having a freight forwarder is beneficial. Forwarding is the bridge between you and your suppliers.

The freight forwarder then delivers the goods to the final destination. Freight forwarder for customs clearance. This includes documentation, cargo tracking, stewardship, etc. This makes the process as seamless as possible for the client. FOB quotes are especially helpful for both novice and experienced importers. Agents provide a hassle-free shipping logistics experience. Delivery is the easiest part, at a convenient pickup location of your choice.

4) DDU, DDP

DDU or DDP is the easiest method used by international customers. This is especially true in the US and Canada. DDP stands for Shipping Paid and DDP for Unpaid Shipping.

- DDP

DDP is the most convenient way to receive a machine in a shorter period of time. This clause stipulates that the supplier handles all the import process. This includes tariffs. The supplier bears the responsibility to ensure the smooth transportation of the goods. The entire process includes quotation fees. Therefore, receiving your machine from China is simple, easy and fast. The import process that most customers worry about is interspersed within the terms of trade. So, as an individual, not having documentation can make you feel overwhelmed. All import duty charges are paid within one quotation. Some suppliers require you to pay duties before shipping. It is then defined as “Unpaid Delivery Tax”

- DDU

In 2010, Incoterms announced the abolition of DDU Incoterms. But in China, manufacturers and suppliers continue to use the word as an option for customers. For most Western countries, Chinese suppliers have freight forwarders. These agents can assist with the import process. All customs and tax logistics are handled, but only in certain countries. Taking DDU or DDP as an optional trade term may not be that simple. This is because it relies on the supplier’s network of freight forwarders. Rather than an experienced forwarder in your specific importing country. Certification and Documentation Requirements for Imported Packaging Machinery in China The requirements for Chinese machinery import documents vary from country to country.

Certificates, safety standards, and compliance regulations are a wide range of regulations. All are necessary units to legally import Chinese machinery and equipment. The purpose of compliance is to ensure the testing of various machinery and products. In order to meet the standard mechanical quality and safety requirements of various countries. Failure to comply with prescribed domestic regulations can lead to several problems. Including paying expensive fines and taking back the machine.

The consequence is that customs authorities choose to keep these shipments. This is pending approval of all necessary regulations. The legal implications of import regulations further enhance the technicality of the process. With the right information on responsibilities and safety parameters, you can avoid any missteps. Below is a description of the documentation for all machinery that needs to be imported from China.

General Documentation Requirements

The bill of lading was one of the earliest general requirements. This is a contract between your supplier and the shipping company. Bills of exchange facilitate the transportation of goods. It lists all cargo and journeys up to the machine’s final destination. Under this Act, there are a few other documents that buyers should be aware of. Once the machinery imported from China reaches the status of the importing country;

- -Certificate of origin to certify that the machine is sold from China.

- Commercial invoices are used for customs clearance procedures.

- Packing list to detail the contents of the goods

- EORI number (the UK only) This serves as an importer’s verification to assist in tracking imported goods.

- Bill of Lading

1) The U.S

The United States is one of China’s major trading partners. The United States dominates China’s machinery imports. China spends trillions of dollars on imports. Therefore, there is a lot of information on regulatory requirements. Here’s how to import packaging machinery from China to the US. Regarding labelling requirements, packaging machinery requires a “Made in China” label. This complies with ISO regulations on importing machinery from China. Mandatory regulations cannot escape compliance rules unless communicated and requested otherwise.

2) UK and EU

UK regulations include all general requirements and CE certificates. Before ordering the machine, make sure it complies with the CE directive. The specific provisions of this decree vary from machine to machine. Attempting to import substandard machinery is illegal and can have unfortunate consequences. This certificate ensures that any imported product into the EU or UK meets safety requirements. Instructions, within the scope of machine instructions, specify a general rule. It said all machines operating in the EU will be tested for safety regulations. All must follow the instructions. The machine must have CE marking and a mandatory user manual.

In addition, there are some electronic regulations that machines need to comply with. For electronics, a general rule of thumb is whether they support socket input. If the answer is yes, then this machine is under the supervision of the EU RoHS directive. The full name of RoHS is “Restriction of Hazardous Substances Directive”. Mechanical and CE documentation requirements in this range require:

- label file

- Declaration of Conformity and User Manual.

3) Australia

The ERAC equipment certification system manages machinery imported from China in Australia. Unlike the EU, Australia does not have a set of standard requirements for imports. The Electricity Regulatory Authority Committee has drafted a compliance regime. This solves the safety issue for motors in Australia and New Zealand.

A certificate of origin and a packaging declaration are required for customs declaration.

Note that hiring a customs broker or freight forwarder can simplify customs procedures. All documentation can be tedious. With these middlemen, customs clearance is faster and less hassle. The timeline from cargo arrival and delivery to a convenient location for your representative is much faster. The imposition of duties on imported goods is a means of generating revenue. This is also to protect a country’s manufacturers/suppliers from foreign competition. The basis for this monetary rule is the value of imported goods, Incoterms and commodity codes. The HS code appears on your commercial invoice.

Counting these different countries seems complicated. If you take responsibility, things get complicated. This means that you are responsible for most of the import process, duties and taxes. This article will explain an easy way to calculate tariffs on any machine imported from China. To check the tariff percentage, visit the company website of your importing country. Type in the HS code: 8422. After this, the duty is calculated by adding the total value, shipping, insurance, and other charges.

- USA: https://hts.usitc.gov/?query=8422.30.9185

- UK:https://www.trade-tariff.service.gov.uk/headings/8422

- Australia: https://www.dfat.gov.au/trade/agreements/in-force/kafta/official-documents/Pages/schedule-of-tariff-commitments-australia

Conclusion

Following these tips can help you find a reliable Chinese supplier of packing machines. By doing some research and taking the time to evaluate your options, you can ensure that your order is processed correctly and arrives safely. Good luck with your sourcing journey!

If you want a trustworthy Chinese supplier of packing machines, you can treat Lintyco to be the team for you.

We are constantly striving to provide our customers with better packing solutions and a better cooperation experience. In addition to the machine product, service is also part of our product.

Customizing a pouch bagging machine is supposed to be so simple. It is easy for you to get the product you need and start production quickly.

We are constantly working hard to make everything better and easier. Looking forward to hearing from you soon!