Packaging Machine For Nail/bolt/screw

Lintyco form fill seal packaging equipment is rugged and durable enough to bag non-food products like hardware, gravel and fertilizers. Constructed of stainless steel and anodized aluminum, our packaging machinery is built to withstand heavy use and provide consistent results.

You can rely on Lintyco machines to perfectly bag irregularly shaped items every time. Our robust and dependable packaging equipment does not require constant monitoring by operators.

Whether producing 100 or 100,000 bags of screws, nails, bolts or other hardware, Lintyco packaging machine will form, fill and seal each bag precisely to your specifications. Large, small or oddly shaped goods pose no issues for our machinery.

Popular Bag Style

Non-Food Packaging Machine Choice

Rotating Premade Pouch Screw Packing Machine

Lintyco Premade Pouch Packaging Machine covers SS304 and adopts German/Japanese electronic components.Package up to 80 Bags/Min. We provide layout drawing service ,OEM service and decent delivery time.

Vertical Form Fill & Seal Nail Packing Machine

The Vertical Form Fill & Seal Machine, a classic solution for Granule packaging, is also one of the choices. Package Up to 60/Min,Low price .If you have no special requirements for the appearance of the product packaging, then it is a good Choice.

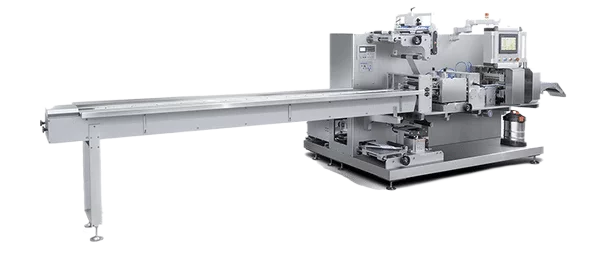

Hardware Form Fill & Seal Machine

Horizontal Form Fill & Seal Machine is used to pack larger blocks,Up to 290 Bags/Min and the Double jaw can double the packaging speed. At the same time, the lower price makes it very suitable for products that adopt low-price strategies.

Ultimate Guide

A wide variety including electronics, hardware, cosmetics, toys, furniture, automotive parts, tools, machinery components etc.

Common formats include boxes, bags, pouches, cartons, shrink wrap, blister packs, custom trays and more based on item dimensions and fragility.

Rates vary by machine size and complexity. Counter-top models pack 50-500 units/hour. Floor machines achieve 500-5000+/hour for high-volume needs.

Option for fully automated or semi-automated machines with integrated counting, weighing, filling, sealing, inspection and ejection functions.

Features like weight/count verification, print/date tracking, leak/burst testing, x-ray inspection, vision controls ensure packaging quality.

Machines can be customized through changeable tools/dies/parts to handle various item shapes and new packaging formats.

Regular service and spare parts supply. Training for operators. Remote troubleshooting support. Performance optimization programs.

Industry&Solution

Don’t Compromise on Material Packaging. Customize with Our Team.

Get A Free Quote Today

Get In touch

available from 10:00 – 19:00

Don’t Compromise On Material Packaging.Customize with Our Team.

Email [email protected]