Introduction to Hardware Packing Machinery

Hardware packaging machines are widely used in tool machinery factories. From small screws and nuts to electronic parts, brand name factories need to use it to screen, fill, seal and transfer. In this article, you will learn about the types of hardware packaging machines, their workflow and applications.

Types of Hardware Packing Machines

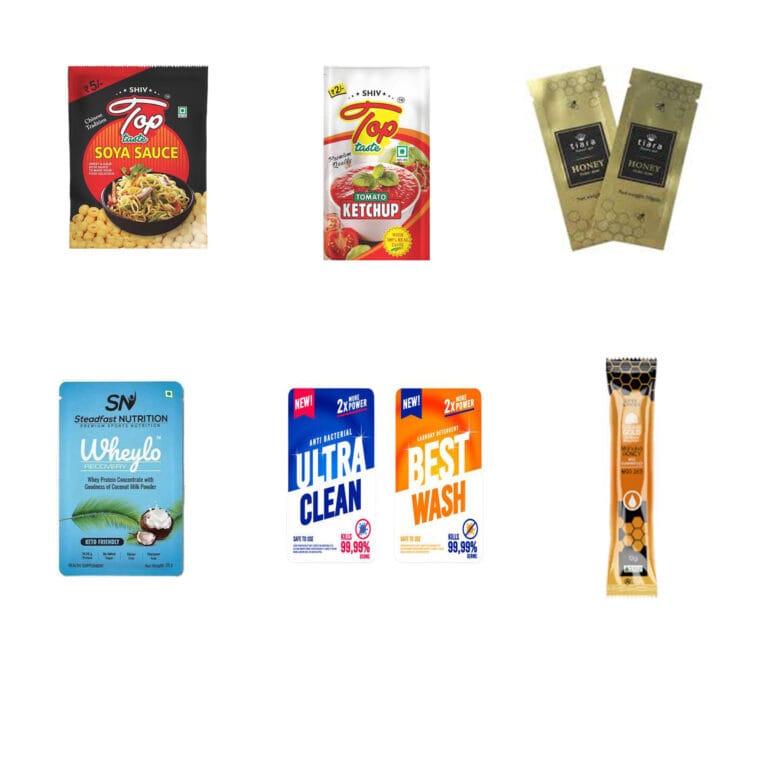

Packing machine is used in hardware packaging, mainly there are several kinds:

1. VFFS packing machine:Vertical packing machine is fast and cheap, so it is the most suitable for hardware packaging. The VFFS packing speed generally is 60 packages per minute.

2.Premade Pouch Packing Machine:The characteristics of the pouch packing machine are stable and easy to change the bag. It is a good choice for customers who have their own bag design.

3.Shrink wrapping machine:Shrink wrapping machine is a machine that wraps products with heat shrink film and then heats it up so that the film shrinks and wraps the product. It is more often used for foodstuffs, such as meat and vegetables.

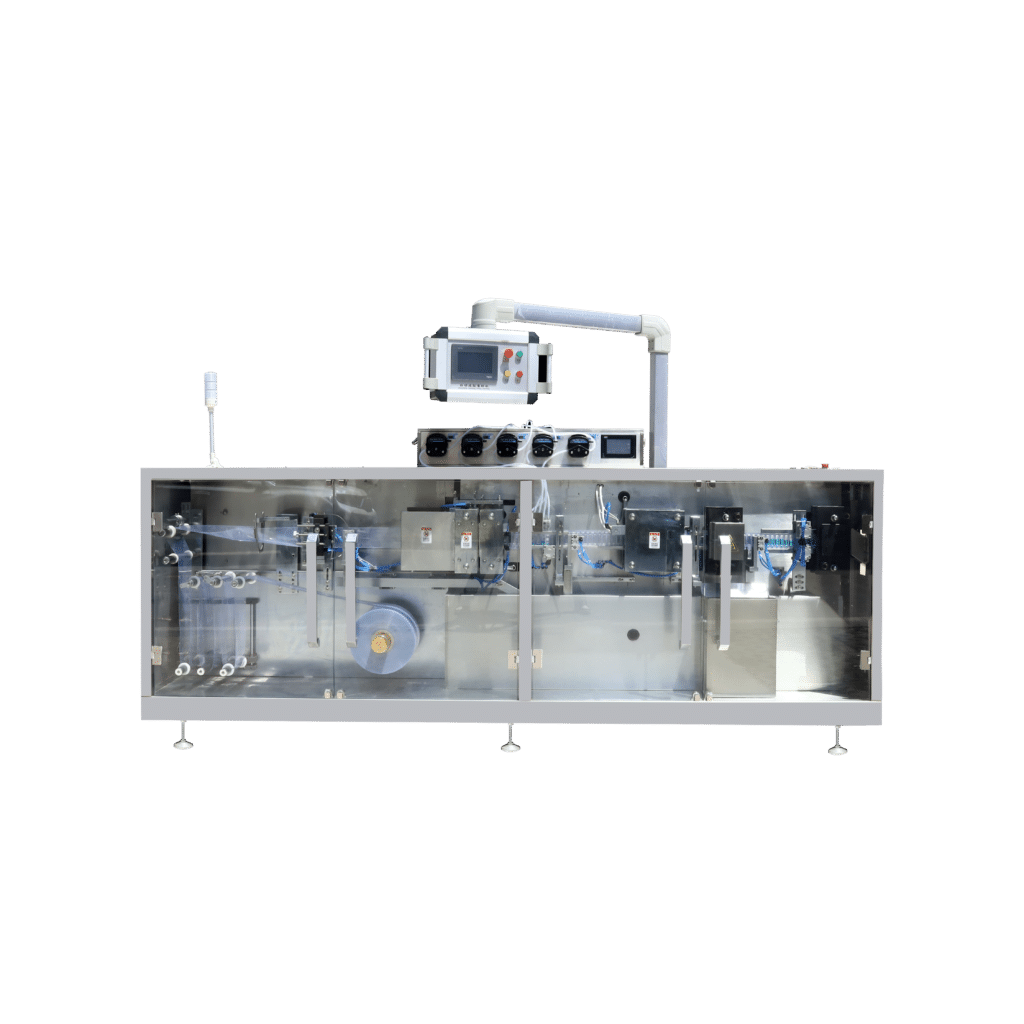

4.Blister packing machine: Blister packing machine is a machine that sucks the heated and plasticised PVC, PE and other thermoplastic coils into various shapes of high-level packaging boxes, frames and other products. Commonly used in daily necessities, small hardware and automotive products.

5 Box Packing Machine: Packaging that has been packed into small packages for carton packaging to facilitate the sale of distributors. This is also a necessary process.

Key Features and Work Process

VFFS packing machine work process

Premade Pouch Packing Machine work process

Benefits of Using Automatic Packing Machinery

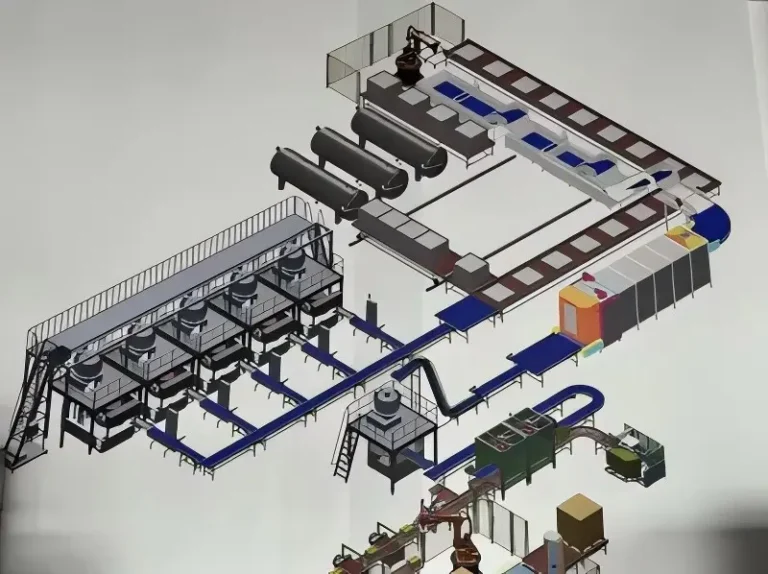

In recent years, the hardware packaging machine from semiautomatic began to a full-automatic tendency. There are weighing systems, screening systems, packing systems, transport systems and sealing system in the automatic hardware packaging system. A set of assembly line operations greatly improves production efficiency, in the past need more than a dozen employees to operate, now only an operator can complete the whole set of machine operations.

At the same time, the machine’s control of standard parts is better than that of human beings, which reduces material costs and after-sales problems. Although the initial investment may be a bit high, the advanced hardware packaging system can significantly save costs, reduce the generation of scrap, and linkage with the inventory system, effective spot troubleshooting.

Industry Applications

Electronics Industry: In this sector, precision and protection from static and physical damage are crucial. Packing machines are used for encasing small, fragile items like semiconductors, circuit boards, and larger consumer electronics like TVs and computers, often with anti-static materials and cushioning.

Automotive Industry: The automotive sector relies on packing machinery for parts ranging from small components like screws and bolts to larger parts like body panels. These machines often handle heavy, irregularly shaped items, requiring robust packaging solutions.

Pharmaceutical Industry: Here, the emphasis is on hygiene, accuracy, and compliance with regulatory standards. Packing machinery is used for blister packs, bottles, and sachets, ensuring products are uncontaminated and correctly labeled.

How to buy a hardware packing machine

Purchasing a hardware packing machine is a significant investment for any business. It requires careful consideration of several factors to ensure that the machine meets your specific needs and offers the best return on investment. Here’s a guide to help you make an informed decision:

Assess Your Packaging Needs

Determine the level of automation based on the type of product to be packaged, its size, and the volume of production. Then determine the type of packaging equipment and auxiliary equipment required.

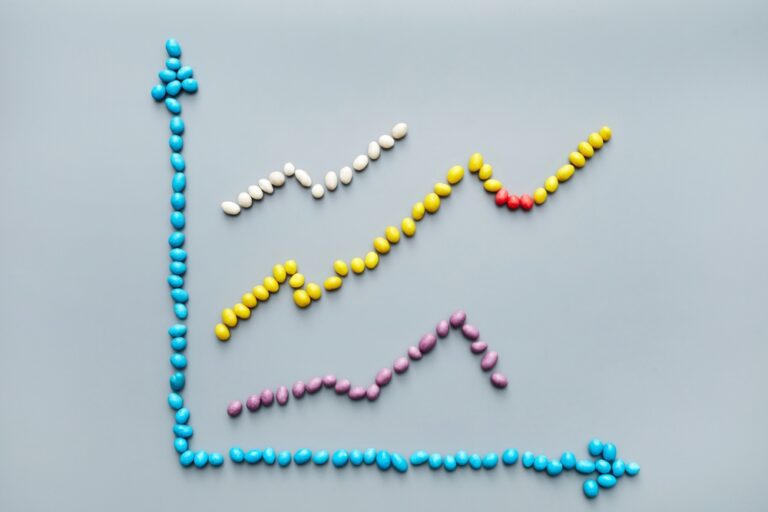

Comparative Analysis of Different Packing Machine Brands

Compare a few of your favourite Packing machine suppliers. Hopefully, Lintyco is also one of your intentions. Each brand has its own characteristics, whether in terms of flexibility, professionalism or service.

Second-Hand vs. New Packing Machines

The advantage of buying a used machine is that it is cheaper, the disadvantage is that there is no maintenance. The advantage of new packaging machines is that they last longer and have maintenance, the disadvantage is that they are more expensive than second hand. Most people will choose new machines when it comes to machines. The opportunity to make money needs to be supported by a good machine. Download Machine ROI Calculator

Calculate the Total Cost of Ownership

Before making a decision, budget the cost of the machine, energy costs and maintenance costs. Ask for a video demonstration and support from the supplier.

After-Sales Service and Maintenance Agreements

Choose a company that offers comprehensive after-sales support. This is because comprehensive after-sales means that the equipment will be durable, last longer and require less maintenance than its counterparts. It is best to choose a company that offers staff training.

FAQ

1.What Are the Different Types of Hardware Packing Machines Available?

Answer: There are several types of hardware packing machines, including Vertical Form Fill Seal (VFFS) machines, Premade Pouch Packing Machines, Shrink Wrapping Machines, Blister Packing Machines, and Box Packing Machines. Each type caters to specific packaging needs and offers distinct advantages.

2.How Does Automation Impact Hardware Packing Machinery?

Answer: Automation in hardware packing machinery enhances efficiency, reduces the need for manual labor, and improves accuracy. Automated machines can integrate various systems like weighing, screening, packing, transporting, and sealing, significantly streamlining the packaging process.

3.Can Hardware Packing Machinery Be Customized for Specific Industry Needs?

Answer: Yes, hardware packing machinery can be customized to meet the specific requirements of various industries, such as electronics, automotive, and pharmaceuticals, each demanding different packaging standards and techniques

Future Trends and Predictions

With the application of AI, automatic packaging machines will be a completely new look. For example, full automation to identify products, AI to reject poor quality products, AI to adjust the optimal running speed, AI smart arm and so on.

Lintyco is a pioneer and leader in automated Hardware Packaging Machines and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.