Why is it that when people think of starting a business nowadays, the first thing that comes to mind is the food business?

In today’s fast-paced food industry, efficiency and precision are key. That’s where food bagging machines come into play. These ingenious devices not only streamline the packaging process but also ensure consistency and quality in food products. In this guide, we’ll delve deep into the world of food bagging machines, exploring their types, benefits, and much more.

What are Food Bagging Machines?

Food bagging machines are automated or semi-automated systems designed to package food products into bags or pouches. From grains and powders to fresh produce and snacks, these machines cater to a wide range of food items. They vary in size, functionality, and complexity, making them a versatile solution for many businesses in the food industry.

For example, a spice powder packing machine may also be suitable for flour packing, depending on the material size and bag size. A paste packing machine may also be suitable for sauce packaging, subject to the material size and bag capacity. The adaptability of food bagging machines depends on factors like the material type and consistency as well as the required bag size.

The Evolution of Food Bagging Machines

The history of food bagging machines started with simple mechanical systems and has advanced to sophisticated, computer-controlled equipment. This progress was driven by the needs for speed, accuracy and the ability to handle various packaging materials and food types.

Fifty years ago, the Industrial Revolution brought great success. We became much more mechanized, transitioning tasks that were once manual to semi-automated and now fully automated machinery.

The types of food that can be packaged have also greatly expanded. Originally only simple granular foods could be packaged, but now powders and liquids can be as well. Packaging machines can also efficiently handle more complex materials, such as pickles with water and particles included.

Types of Food Packaging

- Semi-Automatic Bagging Machines: These require some manual input but still offer a degree of automation. They are suitable for smaller operations or products that need special handling.

- Automatic Bagging Machines: These are high-speed, highly efficient machines ideal for large-scale operations. They can fill, seal, and print labels automatically.there is several packing machine type below.

- Doypack packing machine :The material is filled into the bag and packaged. With this type of machine, food manufacturers can design attractive packaging. And the machine supports flexible packaging, which is more environmentally friendly.

- Vertical form fill seal machine:A traditional model that is fast and inexpensive. All-in-one packaging, relatively small selectivity

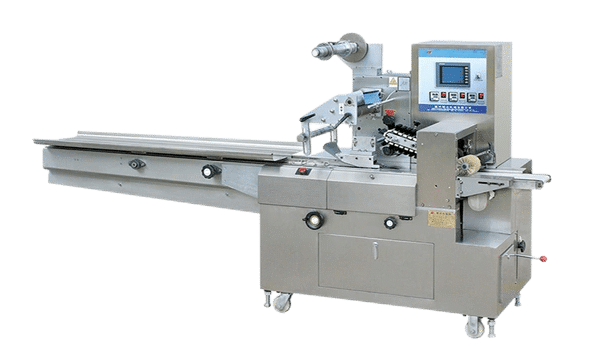

- Pillow flow packing machine:Fast speed, suitable for snack nuts, is the first choice of most food manufacturers

Key Advantages of Automated Food Bagging Machines

- Improved Productivity: Automated functions allow for faster packaging throughput to meet heightened production needs.

- Assured Uniformity: Precise filling and sealing deliver consistent package weights and measures, enhancing brand quality.

- Lowered Operational Expenses: Reduced reliance on manual labor through automation can help streamline costs.

- Safeguarded Product Integrity: Continuous packaging with minimal human contact lessens risks of contamination or accidental damages.

- Scaling Capacity: Robust units are capable of scaling outputs in line with business growth without new hiring.

- Labor Redeployment: Freed-up staff can be upskilled or switched to value-added roles like quality control.

Key Features of High-Quality Food Bagging Machines

- Durability: Look for machines built with high-quality materials that can withstand constant use.

- User-Friendly Interface: Machines should have an intuitive interface for ease of operation.

- Customization: The ability to adjust settings for different products is crucial.

Choosing the Right Food Bagging Machine

When selecting a food bagging machine, consider your product type, packaging speed requirements, and budget. It’s also important to choose a reliable supplier who offers good after-sales support.

Lintyco is a pioneer and leader in automated food and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.

Conclusion

Food bagging machines play an integral role in the modern food industry. They automate routine packaging tasks, bringing significant gains in efficiency, consistency and product quality. Over the decades, these machines have evolved from basic mechanical systems into sophisticated computer-controlled equipment.

Advanced technologies now enable food bagging machines to handle a wide range of foods and packaging materials with high-speed, precision and flexibility. Their automation streamlines operations, allowing businesses to scale up production efficiently. Meanwhile, automated and contactless processes strengthen food safety by reducing contamination risks.

Lintyco is a pioneer and leader in automated Food Bagging Machines and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.