Introduction

According to players in top cosmetic markets, there is a vast cosmetics market worldwide, which is growing the market share of filling machines. Cosmetics are mainly sold through packaging and product presentations. Since cosmetic packaging is often made of glass material, it needs to be protected from damage, so most cosmetic manufacturers pack their products in rigid packaging containers. Cosmetic filling machines are expected to drive sales in the cosmetic and personal care industry as perfumes and deodorants are packed inside cosmetics to sustain their quality until consumption.

Cosmetic Europe has released important findings that estimate that the cosmetics and personal care market in 2024 will be worth approximately US$ 84 billion and is expanding rapidly worldwide. The biggest consumption of cosmetics within Europe is in Germany and France, which accounted for approximately US$ 26 billion in the same year. Therefore, the global cosmetic filling machine market is expected to grow directly in response to the growing global demand for cosmetics.

In this article, we discuss the advantages and disadvantages of cosmetic filling machines, as well as the types, top filling machine manufacturers, and how to choose the right filling machine for you.

What is a Filling Machine For Cosmetics

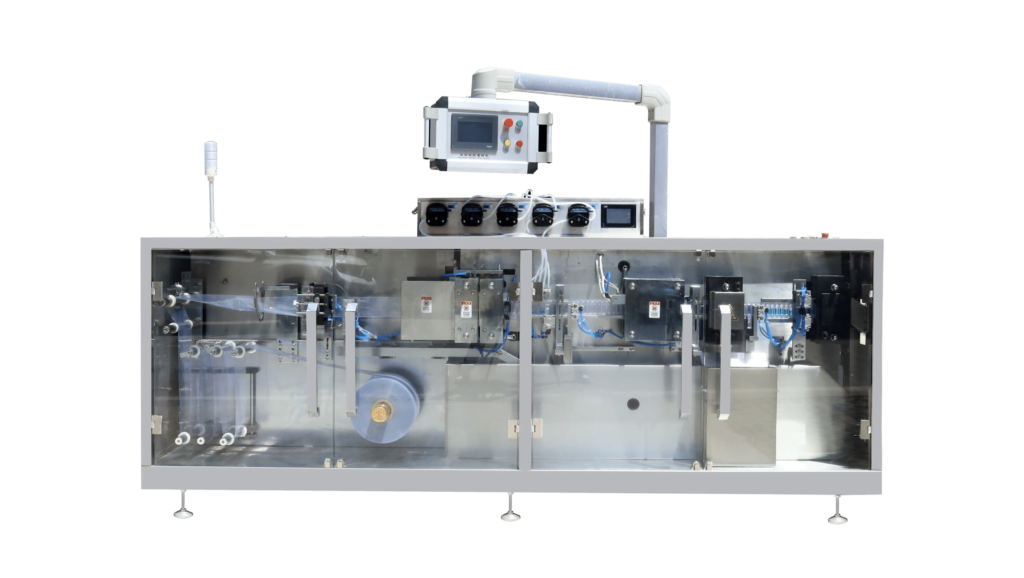

Various cosmetic products can be filled accurately in cosmetic filling machines. There is no one-type filling machine that can be used for all types of cosmetics. Cosmetics come in a variety of forms including solids, liquids, powders, etc. A cosmetic jar filling machine is characterized by its model based on the type of cosmetic product it fills.

For example, there are viscous filling machines for filling lotions and creams. Powder filling machines are also available for filling foundation powder, setting powder, and other powder-based cosmetic products. Serums, rose water, and other water-based cosmetics can be filled with liquid filling machines.

Models of cosmetic filler machines come in a variety of automation levels. Depending on the production capacity and budget, you can select from an automatic filler machine, a semi-automatic filler machine, or a manual filler machine. In addition, cosmetic filling machines are designed for specific purposes such as pouches, containers, tubes, etc.

Different Type of Cosmetic Filling Machines

What are the best liquid filling machines for your business? We’ve compiled all of the information you need, so you won’t have to guess.

By Levels of automation,Cosmetic Filling Machine is Segmented as:

- Manual Cosmetic Filling Machine

- Semi Automatic Cosmetic Filling Machines

- Fully Automatic Cosmetic Filling Machines

By Application, the Cosmetic Filling Machines is Segmented as:

By Operating Speed, Cosmetic Filling Machines is Segmented as:

- Less than 10K PPH

- 10K to 15K PPH

- More than 15K PPH

By Filling Technology, Cosmetic Filling Machines is Segmented as:

- Gravity Fillers

- Pump Fillers

- Piston Fillers

- Overflow Fillers

- Vacuum Fillers

- Net Weight Fillers

| Characteristic/Feature | Gravity Fillers | Piston Fillers | Pump Fillers | Overflow Fillers | Vacuum Fillers | Net Weight Fillers |

|---|---|---|---|---|---|---|

| Viscosity Range | Low to Medium | Low to High | Low to High | Low to Medium | Low to High | Low to High |

| Accuracy | Good | Excellent | Good | Excellent | Good | Excellent |

| Speed | Moderate | Moderate | High | Moderate | Moderate | Moderate |

| Foaming Control | Limited | Limited | Limited | Excellent | Excellent | Good |

| Container Type | Various | Various | Various | Consistent Fill | Various | Various |

| Maintenance Requirements | Low | Moderate | Moderate | Low | Moderate | Moderate |

| Versatility | Medium | High | High | High | High | High |

| Air Removal Capability | Limited | Limited | Limited | No Air Removal | Excellent | Limited |

| Hazardous Liquids | Yes | Yes | Yes | Yes | Yes | Yes |

| Common Applications | Water, juice, beverages, milk, edible oils, personal care products, cleaning and household products, etc. | Sauces, condiments, jams, preserves, cosmetics, personal care products, pharmaceuticals, healthcare products, food, nutraceuticals, industrial and chemical products, etc. | Lotions, creams, shampoos, conditioners, syrups, beverages, sauces, dressings, liquid detergents, cleansers, automotive and industrial liquids, etc. | Beverages, food sauces, condiments, personal care and household products, pharmaceuticals, healthcare products, chemicals and industrial liquids, etc. | Pharmaceuticals, cosmetics, personal care products, chemicals, solvents, food, beverages, laboratory use, etc. | Food, beverages, pet food, agricultural products, chemicals, industrial products, pharmaceuticals, etc. |

9 Things to Consider When Choosing a Cosmetic Filling Machine

Product Characteristics

Assessing your cosmetic product’s viscosity, texture, and consistency is crucial in choosing the right filling machine. Lintyco pack’s range, for instance, can manage everything from light liquids to dense pastes and creams, accommodating a broad spectrum of cosmetic items.

Types of Cosmetics

Determine the type of cosmetics you plan to package. Options include liquid, piston, powder, granule, and capsule filling machines, each suited to different product forms.

Container Variability

Your chosen packaging—be it bottles, jars, tubes, pouches, or airless containers—affects the suitable filling machine. Compatibility with container type, size, and sealing requirements is essential.

Production Volume

Match the filling machine’s speed with your production needs. Levapack’s machines, capable of filling 30 cans per minute, cater to high-demand scenarios, offering efficiency for both small-scale and large-scale operations.

Filling Precision

Opt for machines that guarantee filling accuracy to maintain product quality, minimize waste, and avoid messiness in production areas. Machines equipped with multiple volumetric nozzles ensure precise and efficient packaging.

Maintenance and Cleaning

Ease of maintenance is key for operational efficiency. Select machines with easily accessible parts and straightforward cleaning processes to decrease downtime.

Technical Support

Choosing a supplier that provides quick technical support and maintenance services can be a game-changer, ensuring minimal disruption in case of machine malfunctions.

Customization Capability

Look for machines that offer customization options to meet your specific production requirements. This flexibility can greatly enhance your operation’s efficiency and product quality.

Sustainability and Efficiency

In today’s eco-conscious market, selecting energy-efficient machines that minimize waste and have a smaller environmental footprint can also be a critical factor in your decision-making process.

Leading Brands in Cosmetic Filling Machine Manufacturer

According to Future Market Insights research, during the projected period, the global cosmetic filling machines market is set to enjoy a valuation of US$ 426.3 Million in 2022, and further expand at a CAGR of 3.8% to reach US$ 619.0 by the year 2032. The cosmetic filling machines sales are projected to escalate with the top 5 companies anticipated to hold around 15 to 20% of the global cosmetic filling machines market by the end of 2022.

Based on automation, the automatic cosmetic filling machines segment is projected to remain the leading segment among the other automation segments due to the high adoption of the latest technology and automation by the end-use industries. The target segment is estimated to grow 1.6 times the current market value from 2022 to 2032.

| Market Size 2022 | US$ 426.3 Million |

| Market Size 2032 | US$ 619.0 Million |

| Value CAGR (2022 to 2032) | 3.8% |

| Collective Value Share: Top 3 Countries (2022E) | 20 to 25% |

Top 16 Filling Machine Manufacturers

- E-PAK Machinery, Inc

- Liquid Packaging Solutions, Inc

- Bosch Packaging Technology

- Lintyco Pack

- OPTIMA packaging group GmbH

- Filling Equipment Company Inc

- Accutek Packaging Equipment Company Inc

- Ronchi Mario S.p.A

- Filamatic

- PKB Inc

- Romaco Group

- Paxiom Group

- GEA Group

- Tokyo Automatic Machinery Works Limited

- HongKong SINBON Industrial Limited

Filling Machine for Cosmetics from Lintyco You Can Trust

In industries such as cosmetics, food processing, and wine & beverage, we serve some of the largest and most successful companies. Our goal is to provide the best products at a competitive price for our customers.

Make Your Production Worry-Free with Automation Technology

Cosmetics use the same type of machines to meet the varying product consistencies, so the filling process isn’t much different from food and beverage. Cosmetic filling equipment must get the amount per container just right, even if the substance is thick as paste.

By automating the filling process, you can ensure a worry-free production experience and minimize the potential for human error. In addition, these automated filling machines are known for their high precision filling and high-speed filling.

Providing custom packaging lines for bags and cans

Filling machines, seaming machines, capping machines, labeling machines, coding machines ,tube packing machines and doypack machines are just a few of the packaging machines offered by Lintyco. The packaging line solutions offered by Lintycopack are of the highest quality and are backed by unparalleled technical support.

FAQ

Q1:What is a cosmetic filling machine?

A: A cosmetic filling machinery is used in the cosmetics industry to fill tubes/pouches/blisters/jars with various products like creams, gels, lotions, and ointments .

Q2:How does a cosmetic filling machine work?

A: In general, cosmetic filling machines measure and dispense a precise volume of product into containers or tubes, though specifics vary by model. In some machines, the volume of product dispensed depends on the settings on the machine.

Q3:What types of products can be filled with a cosmetic filling machine?

A: It is possible to fill a wide range of cosmetic products using cosmetic filling machines, including creams, gels, lotions, and ointments.

Q4:How do I choose the right cosmetic filling machine for my needs?

A: Choosing the right machine depends on a number of factors, including the type of product you’re filling, the volume of production, the type of container, and any specific features you may require.

Q5:Are there manual and automatic options for cosmetic filling machines?

A: Choosing the right machine depends on a number of factors, including the type of product you’re filling, the volume of production, the type of container, and any specific features you may require.

Conclusion

In summary, the growing global demand for cosmetics, driven by innovations in product presentation and packaging, is steering the cosmetic filling machine market towards remarkable growth. As we’ve explored, selecting the right filling machine is pivotal for manufacturers looking to optimize their production lines for efficiency, precision, and adaptability. The variety in cosmetic products and packaging requires a careful evaluation of machine capabilities, including automation level, container compatibility, filling accuracy, and maintenance ease. Leading brands like E-PAK Machinery and Lintyco Pack are at the forefront of providing cutting-edge solutions that cater to this dynamic industry’s needs. By embracing advanced technologies and considering factors like sustainability and technical support, businesses can not only enhance their operational efficiency but also contribute to a greener planet. As the market continues to evolve, staying informed about the latest trends and innovations in filling

Before you go……

Finding the right machine is just the first step. Even the world’s best machines will breakdown if you don’t adjust them correctly! Read my next article to ensure that improve efficiency and productivity right now

Unlocking the Potential of Turnkey Packaging Solutions

Get your Packaging Machine Support and Maintenance

HOW TO PROPERLY CLEAN YOUR HORIZONTAL FORM FILL SEAL MACHINE