Introduction

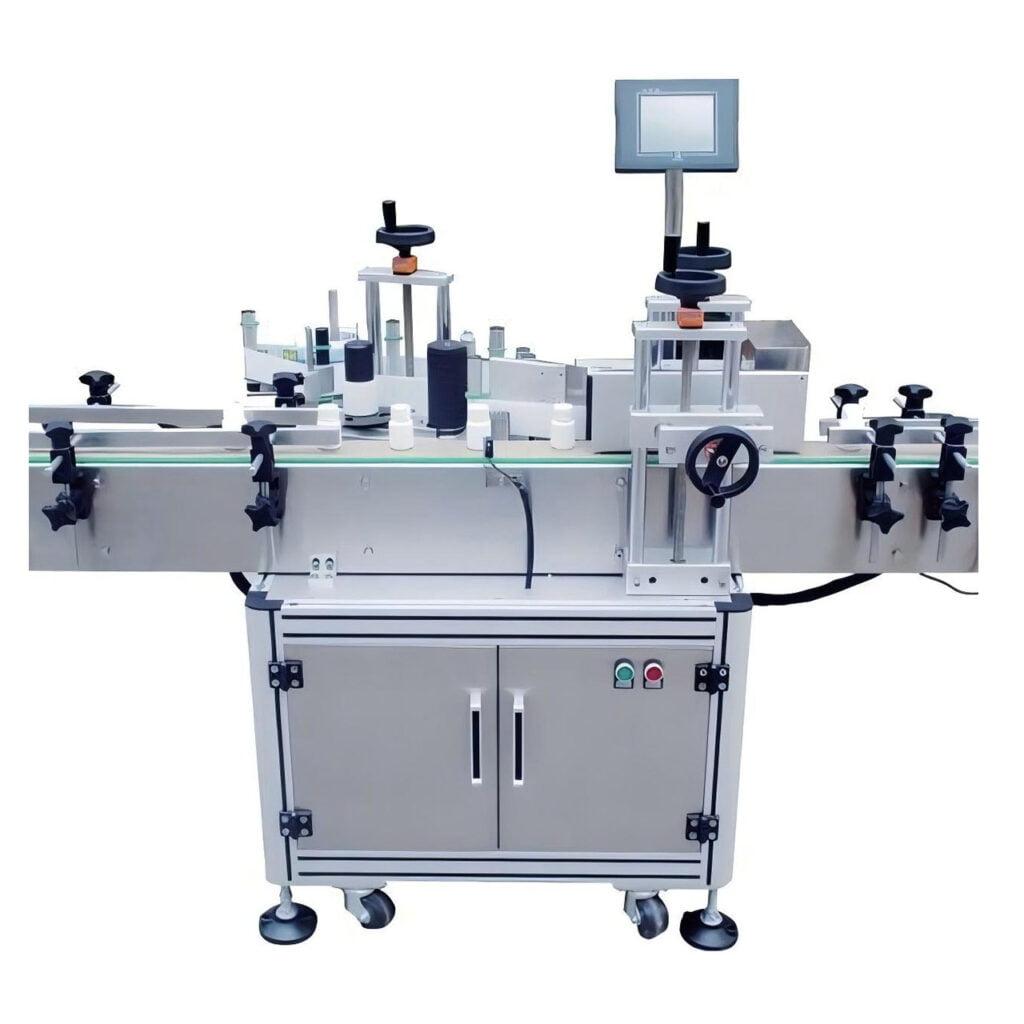

Automatic labeling machine is a kind of equipment used for labeling, which is widely used in the packaging process of commodities, electronic products, pharmaceuticals and other industries.

Like we use in our daily life shampoo, drink drinks above the label, is the use of labeling machines to complete the labeling work. Labeling machine classification has semi-automatic labeling machine and automatic labeling machine, from the name above it seems that we can easily understand, it is only the degree of automation, the higher the degree of automation, the more expensive.

Type of Automatic Labeling Machine

Automatic labeling machines can be categorized based on several criteria:

Degree of Automation

- Manual Labeling Machines: Require manual placement and removal of products.

- Semi-Automatic Labeling Machines: Require manual placement of products but initiate labeling automatically.

- Fully Automatic Labeling Machines: Integrate into production lines and handle labeling without manual intervention.

Labeling Type

Automatic round bottle labeling machines

Automatic Labeling Machine for Bottles are designed to apply labels to cylindrical containers such as bottles, jars, and tubes. These machines are widely used in industries like food and beverage, pharmaceuticals, and cosmetics due to their efficiency and precision.

Key Features

- High Speed and Precision: Machines like the Lintyco-PACK® Round Bottle Labeling Machine can label between 10 to 30 products per minute, ensuring consistent label placement without manual intervention.

- Versatile Labeling: Compatible with various label sizes and bottle dimensions, making them suitable for different product lines.

- User-Friendly Operation: Equipped with touch screens for easy adjustments and settings configuration, enhancing user experience.

- Stable Performance: High standard PLC control systems for stable high-speed operation.

Automatic Tube Labeling Machines

Automatic tube labeling machines are specialized for labeling cylindrical tubes, such as those used for cosmetics, pharmaceuticals, and laboratory samples.

Key Features

- High Efficiency: Machines like the Automatic Tube Label Applicator are designed for high efficiency and versatility, capable of handling various tube sizes and label types.

- Precision Engineering: Ensures accurate label application, enhancing product presentation and operational workflows.

- Customizable Options: Machines can be tailored to specific needs, including options for different print engines and label materials.

- Speed: Some machines can label up to 60 tubes per minute, providing a fast and reliable solution for high-volume production.

Automatic Bag Labeling Machines

Automatic bag labeling machines are designed to apply labels to various types of bags, including ziplock, doypack, wicket bags, flat bags, and stand-up pouches.

Key Features

- Versatility: Machines like those from Lintyco Pack can label filled or unfilled bags, applying labels on the top, bottom, or both sides as required.

- Precision and Speed: Machines like the Nita Joust SSK-FLO use ultra-precise servo motors and synchronized conveyors to prevent bag skewing and wrinkling, ensuring straight and accurately applied labels.

- Custom Solutions: Capable of handling specific challenges such as labeling very large bags, applying multiple labels on the same pouch, or integrating with other production line equipment.

- User-Friendly: Features like intuitive changeover systems and live tech support make these machines easy to operate and maintain

Automatic Labeling Machine Application

Automatic labeling machine is a kind of equipment used for labeling, its main uses include the following aspects:

- commodity labels: automatic labeling machine can be used to label commodity bar code, production date, shelf life and other information, improve the efficiency and accuracy of the commodity.

- packaging labels: automatic labeling machine can be labelled on the packaging, marking the product name, specifications, production batch and other information, to facilitate product traceability.

- logistics labels: automatic labeling machine can be labelled on the transport packaging, marking the destination of the goods, the consignor, consignee, mode of transport and other information, to enhance the logistics transport limbs to remove the cherry blossom transport tracking, sorting and distribution efficiency.

- food labeling: automatic labeling machine can be used to label the nutritional composition of food, consumption methods, ingredient list and other information, to meet the requirements of food safety labeling, to facilitate consumer choice.

- pharmaceutical labels: automatic labeling machine can be labelled on the pharmaceutical packaging, marking the name of the drug, dosage, manufacturer, batch calendar series of permitted document number and other information, to facilitate the identification of drugs.

In general, automatic labeling machines are mainly used in various industries to label products, improve production efficiency, reduce manual * work, and ensure the accuracy and consistency of the label.

Printing Principle of Industrial Labeling Machines

Many people often ask about industrial labeling machines, in fact, is what we often say, the main structure of the labeling machine printing is a bar code printer, we do real-time printing and labeling, it is on the basis of its increased mechanical labeling arm, electrical equipment, computer control equipment, racks, etc., so that down to the formation of a number of standard fully automated printing and labeling machine to provide some do automated packing After the section of the company supporting the use of.

Thermal transfer printing and thermal printing are two methods of barcode printing. Each method uses a thermal print head to heat the print surface. Thermal transfer printing uses a heated ribbon to print a durable, long-lasting pattern on a variety of materials. Instead of using a ribbon, thermal printing prints a pattern directly on the label material.

Thermal printing and thermal transfer printing are the best barcode printing technologies because they can be easily applied to a wide range of adhesive label materials and print accurate, high-quality graphics with excellent edge definition. Each technology is capable of producing 1D and 2D barcode characters with patterns and text fonts at the same print clarity and speed.

The following sections will help you understand the differences between the technologies and how to select the appropriate print method for your application.

Thermal Printing

Thermal printing uses chemically treated thermal media that turns black as it passes under the thermal print head. Thermal printers do not use ink, toner or ribbons. The simple design makes thermal printers durable and easy to use. Because there is no ribbon, thermal printers are less expensive to operate than thermal transfer printers.

Patterns on thermal media fade over time. If the label is overexposed to heat, light, or other catalysts, the material will darken, making the barcode unreadable. The readability of thermal labels varies greatly with conditions of use, but the technology provides adequate life for rated labeling and many other common bar code printing applications. For example, after six months of storage in a distribution centre, direct thermal labels can still be easily scanned and read.

Thermal Transfer Printer

In thermal transfer printing, the thermal printhead heats the ribbon and the ink melts onto the label material to form a pattern. The ribbon material is absorbed by the media and the pattern forms part of the label. This technology provides pattern quality and durability unmatched by other on-demand printing technologies.

Thermal transfer printers accept a wider variety of media than thermal printers, including paper, polyester and polypropylene materials. Thermal transfer printers produce durable rating labels, UL/CSA labels, stickers and tickets, as well as wristbands, permanent asset stickers, rack tags and other identification.

Thermal transfer printers are available with wax or resin ribbons.Wax is the most common, inexpensive option for many labeling applications. Resin ribbons provide improved heat and chemical resistance and are mostly used for synthetic labeling materials. Resin-modified wax ribbons combine the best of both worlds and perform well on many label materials.

Frequently Asked Questions (FAQs)

1. How does an automatic labeling machine work?

It typically uses a conveyor system to transport products, sensors to detect product presence, a label applicator to apply labels, and a control system to manage operations.

2. What labeling speeds can automatic machines achieve?

Speeds vary widely depending on the model, from 20-50 products per minute for semi-automatic machines to up to 300 units per minute for industrial-grade machines.

3. What factors should be considered when selecting an automatic labeling machine?

- Manufacturer Credibility

- Machine design and efficiency

- Power requirements

- Technology and technical parameters

- Configuration (commercial vs. small-scale)

- Label spool loading ease

- Downtime frequency

- Rejection capabilities

- Compatibility with other equipment

- Availability of spare parts

- Ease of use and maintenance

4.How do fully automatic and semi-automatic labeling machines compare?

Fully automatic machines offer higher speeds and require less human intervention but are more expensive. Semi-automatic machines are more suitable for smaller batches and lower production volumes.

Conclusion

Automatic labeling machines are vital for efficient and accurate labeling in various industries. They offer numerous features and benefits, including high precision, speed, and versatility, making them indispensable in modern production environments. Whether for small businesses or large-scale manufacturing, there is an automatic labeling machine to meet every need.

Now that you understand the different types of industrial labeling machines, it’s important to select the right machine for your business.

So, what type of automatic labeling machine is best for your business? That answer depends on the products you are looking to package and the level of automation you need.

If you are unsure which machine would be a good fit for your company, contact Lintyco pack

At Lintyco Pack , we can help you find the perfect machine for your needs. We have a wide selection of machines and knowledgeable staff who can answer any questions you may have about selecting the right packaging machine for your business.