Are you looking for a solution to properly feed parts to the next stage of production? Then you have come to the right place! We at Lintyco can design the right solution in feeding technology for almost every industry.

In this artical, you will find the benefits,type of automatic feeding system, application and Lintyco service.

Benefits of Automatic Feeding Systems in Packaging

- Increased Productivity: Automating processes reduces manual intervention and streamlines processes, boosting production rates.

- Consistency and Quality Control: Automated systems reduce variability and errors associated with manual product handling.

- Cost Efficiency: With automated feeding systems, labor costs are lowered and waste is minimized.

- Enhanced Safety: By reducing human contact with machinery and products, workplace injuries and contamination are reduced.

- Scalability: With these systems, increased production demands can be accommodated easily without extensive modification.

Types of Automatic Feeding Systems

Vibratory Bowl Feeders

The vibratory bowl feeders utilize vibration and gravity to sort and orient products, ensuring a consistent flow into packaging machines.They provide precise sorting and orientation, reducing manual labor and increasing throughput while maintaining product integrity.

It is commonly used for aligning caps, positioning snack products, and feeding delicate items like confectioneries.

Centrifugal Feeders

Operating on centrifugal force, these feeders deliver products at high speeds, ideal for high-volume operations.The centrifugal is capable of feeding thousands of parts per minute, they enhance production efficiency while minimizing damage to products.

It is suitable for packaging items like bottles, caps, and jars, especially those that require gentle handling.

Friction Feeders

Friction Feeders use friction to move products through the packaging line, often integrating with coding and labeling machines. They allow for batch counting and precise handling, improving accuracy and reducing waste.

It is effective for feeding printed materials, pouches, and other flat items.

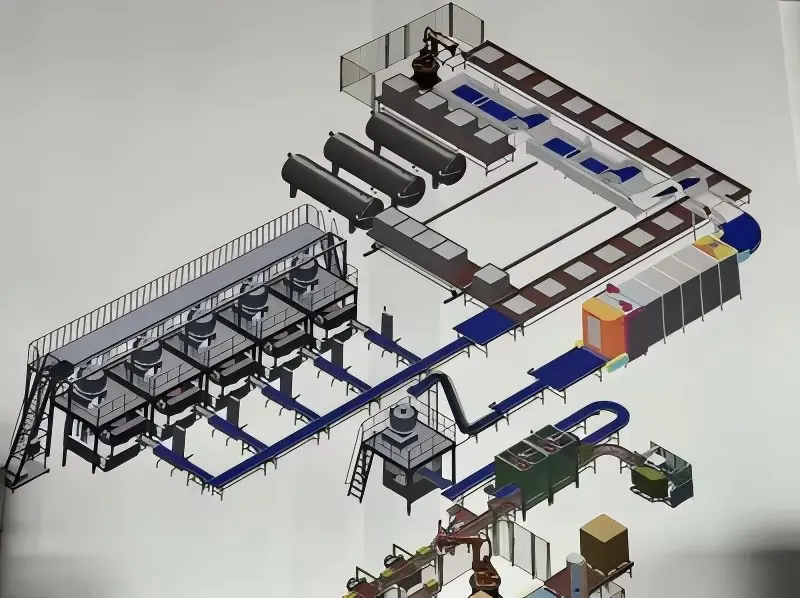

Custom Automated Feeding Systems

Tailored solutions that can integrate various feeding technologies to meet specific production needs.Customization allows for flexibility in handling different product shapes and sizes, enhancing overall operational efficiency.

It is used across diverse industries, from food to pharmaceuticals, where precise feeding is critical.

Application of Automatic Feeding System

Chemical, Feed, and Grain Industries

The Lintyco fully automatic filling system is suitable for a variety of packaging materials, such as paper bags, woven bags and plastic bags, etc. It is widely used in the chemical, feed and grain industries. It has an automatic bag feeding device, control and safety devices, and uses a servo motor drive device to improve efficiency.

- Bulk Material Handling: The feeding systems are essential for conveying bulk solid materials like chemicals, grains, and feed. They can weigh, mix, and transport powders and particles to production machines, ensuring a continuous and efficient workflow.

- Dust Control: These systems often include features to minimize dust pollution, which is crucial in industries dealing with fine powders. For example, materials are transported in sealed containers and pipes to maintain a clean working environment.

- Versatility: They are suitable for various products, including dyes, paints, coatings, fertilizers, and animal feed, making them vital in sectors that require precise material handling and processing.

Food, Condiments, Health Products, and Other Fields

The automated packaging equipment and solutions provided by Lintyco Pack are widely used in food, condiments, health products, daily chemicals, pet food, medicine and other fields.

- Food Packaging: In the food industry, automatic feeding systems facilitate the packaging of diverse products, from snack foods to liquids. Systems like the LTC-420 vacuum sealer can handle both solid and liquid goods, packaging them into durable, vacuum-sealed pouches at high speeds (up to 60 packages per minute) .

- Health Products: Similar systems are used for packaging health supplements and pharmaceuticals, ensuring that products are sealed and protected from contamination during transport and storage.

- Traceability and Compliance: Automated systems provide end-to-end traceability of the packaging process, which is critical for compliance with health and safety regulations in the food and pharmaceutical industries .

Fastener Packaging

- Precision and Speed: The Lintyco fully automatic screw packaging machine realizes a fully automated packaging process and is suitable for automatic packaging of fasteners such as screws, nuts, bolts, screws, washers, etc. These systems can quickly sort, orient, and package fasteners into boxes or bags, significantly increasing production speed compared to manual methods.

- Robotic Integration: Many fastener packaging lines incorporate robotic feeding systems that can handle various sizes and shapes of fasteners, ensuring consistent quality and reducing the risk of human error during the packaging process .

- Customization: Automatic feeding systems can be customized to handle specific fastener types, allowing manufacturers to adapt to changing production needs without extensive downtime.

Our service to the feeding technology by Lintyco

You will receive the following service offer for our feeding technology:

- Drive technology basic training as well as hands-on workshops on drives and applications

- Maintenance, spare and wear parts service

- Diagnostics with the innovative laboratory measuring device QRG1

- Controlled series production with quality assurance through drive check and documentation of relevant, drive-specific characteristic values

Conclusion

The automatic feeding system is an indispensable part of packaging machinery. It can realize the efficient, accurate and continuous supply of materials, thereby improving the automation and production efficiency of the entire production line.

Would you like to have all additional information about Lintyco‘s feeding technology systems and components available at a glance, even offline?

We are pleased to address any queries you may have about feeding technology. In addition to the well-known precision feeders, we provide a comprehensive portfolio of fast and precise handling systems, transfer systems, rotary indexing table alternatives, and other complex automation solutions – all tailored to the highest standards for each of our customers and with the claim of providing the best solution in every industry.