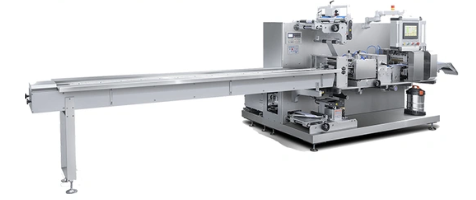

As the demand for packaged goods continues to rise, the packaging industry is constantly seeking new ways to improve efficiency, reduce costs, and enhance the quality of their products. One technology that has been gaining significant traction in recent years is the Horizontal Form Fill and Seal (HFFS) machines. These machines offer a range of benefits, including high-speed packaging, reduced labor costs, and minimized material waste. In this article, we will explore the future of HFFS machines, including the latest trends, advancements, and their potential impact on the packaging industry.

The Latest Trends in HFFS Machines

HFFS machines have undergone a significant transformation over the years, with new innovations and advancements being introduced at an unprecedented pace. Some of the latest trends in HFFS machines include:

- Sustainability: As consumers become more environmentally conscious, there is an increasing demand for eco-friendly packaging solutions. HFFS machines are capable of using thinner films and reducing the overall amount of packaging material needed, leading to a more .

- Automation: With the advancements in robotics and machine learning, HFFS machines can now be fully automated, reducing the need for human intervention in the production process. This results in increased production speed and efficiency, while also minimizing the risk of errors.

- Flexibility: HFFS machines can now handle a wide range of packaging materials, including flexible pouches, sachets, and bags. This flexibility allows manufacturers to produce a variety of product sizes and shapes, providing greater options for the end consumer.

Advancements in HFFS Machines

The HFFS machines have been continuously evolving, incorporating new technologies and advancements to provide a more efficient and effective packaging process. Some of the latest advancements in HFFS machines include:

- Smart sensors: HFFS machines are now equipped with smart sensors that can detect any anomalies in the packaging process, such as product jams or film tears. This allows the machine to automatically stop and prevent any damage to the product or machine.

- Remote monitoring: HFFS machines can now be monitored remotely, providing real-time data on the production process. This data can be used to identify any issues or inefficiencies, allowing manufacturers to optimize their production process and reduce downtime.

- Machine learning: HFFS machines can now learn from their production process, analyzing data to identify patterns and optimize the machine’s performance. This results in increased efficiency, reduced waste, and improved product quality.

FAQs:

Q: What Are Horizontal Form Fill and Seal (HFFS) Machines?

A: Horizontal Form Fill and Seal (HFFS) machines are advanced packaging systems used for a variety of products. They form the package, fill it with a product, and then seal it, all in a horizontal fashion, making them ideal for packaging solid, granular, or liquid products.

Q: What Advancements Are Being Made in HFFS Machines?

A: Recent advancements in HFFS machines include integration of IoT and AI for smarter operation, improved speed and efficiency, better user interface, and more sustainable packaging options with minimal material waste.

Q: How Do HFFS Machines Improve Packaging Efficiency?

A: HFFS machines improve packaging efficiency by automating the packaging process, ensuring consistent product quality, increasing output speed, and reducing labor costs.

Q: How Does Lintyco Support Customers with HFFS Machine Solutions?

A: Lintyco offers a comprehensive range of HFFS machines tailored to meet the specific needs of different industries. They provide expert consultation, installation, training, and after-sales service to ensure optimal performance and customer satisfaction.

Conclusion:

The future of horizontal form fill and seal machines is promising, with new innovations and advancements continuously being introduced to improve efficiency, reduce costs, and enhance the quality of products. As sustainability and automation become increasingly important in the packaging industry

Lintyco is a pioneer and leader in automated HFFS Packaging Machines and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.