Ever wondered how your favorite chocolate bar maintains its pristine condition from the factory to your hands?

The unsung hero behind this magic is the chocolate packing machine. These ingenious devices have revolutionized the confectionery industry, ensuring chocolates are packaged efficiently, hygienically, and attractively.

Let’s delve into the world of chocolate packing machines and uncover their sweet secrets.

The Evolution of Chocolate Packing Machines

Do you curious about history of chocolate packaging ?

From Hand Wrapping to Automation

In the early days, chocolates were meticulously wrapped by hand—a labor-intensive process prone to inconsistencies. As demand soared, the need for faster and more reliable packaging methods became evident. Enter the chocolate packing machine, transforming the industry with automation and precision.

Milestones in Packaging Technology

Early 20th Century: Introduction of semi-automatic machines that combined manual feeding with mechanical wrapping.

Mid-20th Century: Development of fully automatic machines capable of high-speed operations.

21st Century: Integration of robotics and AI, enhancing flexibility and efficiency in packaging.

Understanding Chocolate Packaging Requirements

Chocolate packaging isn’t just about wrapping products – it’s about preserving flavor, preventing contamination, and ensuring products reach consumers in perfect condition. Modern chocolate packing machines combine precision engineering with advanced technology to meet these demanding requirements.

- Airtightness and oxygen barrier

- Moisture resistance

- Temperature protection

- Light protection

- Physical damage prevention

Common Packaging Materials

- Aluminum foil (primary choice for bars)

- Plastic films

- Cardboard and paper

- Biodegradable materials

- Composite materials

Types of Chocolate Packing Machines

Primary Packaging Machines

Manual Chocolate Packing Machine

The chocolate packaging equipment instructions is intended primarily for small-scale businesses. It is the finest solution for chocolatiers, whether they are artisanal or just starting out.

Chocolate Foil wrapping systems

Chocolate foil wrappers contain special foils. It has several advantages, including the ability to adjust the scale of the wrap, high productivity, and appealing packaging.

Chocolate Bar Packing Machine

Chocolate bar wrappers% bars are wrapped in cardboard or aluminum. They can also seal them airtight. It is an excellent approach to create diverse packaging designs and will boost productivity through the usage of computers.

Chocolate Coin Packing Machine

The chocolate wrapping machine specializes in wrapping candies that resemble dollars and features a contemporary servo system for simplicity of usage.

It is completely silent and autonomous, and can be smoothly integrated into the manufacturing line. It has a low initial cost and requires a large amount of space.

Ideal for high-speed operations, flow wrappers continuously wrap chocolates in a film, sealing them on all sides. They’re perfect for bars and molded chocolates.

Individual piece wrapping units

Secondary Packaging Systems

- Cartoning machines

- Box filling systems

- Tray packers

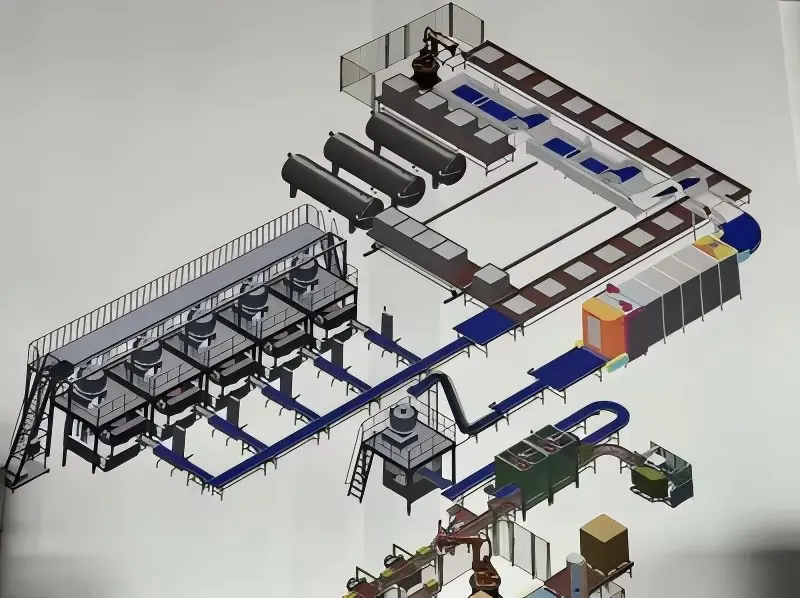

Complete Packaging Lines

- Integrated systems

- Multi-function units

- Automated solutions

How Chocolate Packing Machines Work

Key Components

A typical chocolate packing machine comprises:

- Feeding System: Guides chocolates into the machine.

- Wrapping Mechanism: Envelops chocolates in packaging material.

- Sealing Unit: Ensures packages are airtight.

- Control Panel: Allows operators to adjust settings and monitor performance.

Chocolate Packaging Process

Feeding: Chocolates are placed onto a conveyor belt.

Wrapping: Packaging material is cut and wrapped around each piece.

Sealing: Edges are sealed to protect the contents.

Labeling: Packages are labeled with branding and information.

Inspection: Finished products are checked for quality before dispatch.

Benefits of Modern Packing Machines

Modern packing machines make packaging faster, easier, and better. Here’s how they help:

Why They’re Great

Faster Production: Machines can pack chocolates much quicker than people can.

Lower Costs: They save money because fewer workers are needed.

Better Quality: The packaging is always neat and consistent.

Less Waste: Machines use just the right amount of materials, so nothing is wasted.

Cleaner Process: They keep everything hygienic and reduce the chance of germs.

How They Check Quality

Automatic Inspections: Machines can spot problems without human help.

Weight Checks: They make sure each package has the right amount of chocolate.

Seal Testing: They check that packages are sealed properly so nothing leaks.

Safety Scans: Machines look for things that don’t belong, like tiny pieces of metal or plastic.

Tips for Using Automatic Packing Machines

How to Take Care of Them

Keep Them Clean: Clean the machines often to keep them working well.

Check the Parts: Look at the parts regularly to make sure nothing is worn out.

Calibrate: Adjust the machines to keep them accurate.

Prevent Problems: Fix small issues before they become big problems.

How to Use Them Safely

Start-Up Steps: Follow instructions to get the machine running.

Watch While It Works: Keep an eye on it to make sure it’s running smoothly.

Do Quality Checks: Check the packaging to ensure it looks good.

Turn It Off Right: Shut it down properly when done.

Why Invest in Modern Machines?

Costs to Think About

- Buying the Machine: Machines can cost a lot at first.

- Installing It: You’ll need help setting it up.

- Training Workers: Employees need to learn how to use it.

- Running Costs: Power, materials, and other things can add up.

- Upkeep: Taking care of the machine costs money too.

How They Save Money

- More Efficient: They work faster, so you can make more chocolates.

- Fewer Workers Needed: This saves on salaries.

- Less Waste: They use packaging materials wisely.

- Better Quality: Fewer mistakes mean happier customers.

Modern packing machines may cost a lot upfront, but they’re worth it because they save time, money, and materials in the long run!

Challenges in Chocolate Packaging

Even though there have been many improvements in chocolate packaging, there are still some challenges that chocolate manufacturers face:

Temperature Sensitivity: Chocolates can melt if they get too warm during packaging. This means packaging machines need to keep the chocolates at the right temperature to avoid ruining them.

Fragility: Chocolates are delicate and can break easily. Special care is needed to handle them gently, especially for softer chocolates or those with fillings.

Food Safety Rules: Chocolates need to be packaged in a way that keeps them safe to eat. Chocolate manufacturers must follow strict rules to make sure the packaging keeps the chocolate clean and fresh until it reaches you.

These challenges show how important it is to have good packaging technology and careful handling in the chocolate-making process.

Future Trends For Chocolate Business

The future looks promising with trends like:

- Automation: Increased use of AI and robotics.

- Sustainability: Greater emphasis on recyclable materials.

- Personalization: Tailoring packaging to individual consumer preferences.

Advancements in chocolate packaging are driven by a combination of technological innovation, environmental responsibility, and consumer preferences. From automation and sustainability to smart features and visual appeal, these innovations not only protect the chocolate but also enhance the overall consumer experience. Whether it’s eco-friendly wrappers or AI-powered machines, the future of chocolate packaging is as sweet as the treats themselves!

FAQs

1. What is a chocolate packing machine?

A chocolate packing machine automates the process of wrapping and sealing chocolates, ensuring efficiency and hygiene.

2. How does a chocolate packing machine work?

It feeds chocolates into the system, wraps them with packaging material, seals the packages, and prepares them for distribution.

3. Why is packaging important for chocolates?

Packaging protects chocolates from contamination, preserves freshness, and enhances visual appeal.

4. Can one machine handle different chocolate shapes?

Many modern machines are versatile and can accommodate various shapes and sizes, but it’s essential to verify specifications before purchase.

5. How often should a chocolate packing machine be serviced?

Regular maintenance, including cleaning and inspection, should be performed as per the manufacturer’s guidelines to ensure longevity and performance.

Conclusion

Chocolate Packing Machine are more than just equipment—they’re guardians of taste and quality. By addressing critical packaging requirements like airtightness, moisture resistance, and protection from environmental factors, they preserve the delicate nature of chocolate while meeting increasingly complex consumer and regulatory demands.

Investing in the right chocolate packing machine is crucial for any chocolate manufacturer. Understanding your specific needs, available options, and operational requirements will help ensure a successful implementation that enhances your production capabilities.

Do not hesitate to Contact us Now .