Packaging is very important for biscuits. Good packaging keeps biscuits fresh, ensures quality, and makes them look attractive. To make packaging work well, biscuit makers often use biscuit packing machines. These machines automate the packaging process, reducing the need for people to do it by hand. This speeds up production.

In this guide, we will look at how biscuit packing machines work. We will cover:

- The different types of biscuit packing machines

- The benefits of using these machines

- Important things to consider when buying a machine

- Tips for maintaining the machines properly

- Safety guidelines for operating the machines

How Does a Biscuit Packing Machine Work?

Biscuit packing machines have different parts and mechanisms that work together to properly package the biscuits. The packaging process typically involves:

- Feeding the biscuits into the machine

- Handling the packaging material like rolls of film or foil

- Orienting the biscuits so they are packaged uniformly

- Sealing the packaging material to create individual packs

- Cutting the sealed packs into individual units ready for distribution

- Discharging the packaged biscuits onto a conveyor belt or packaging line

Types of Biscuit Packing Machines

There are different types of biscuit packing machines available, each designed for specific packaging requirements. The common types include:

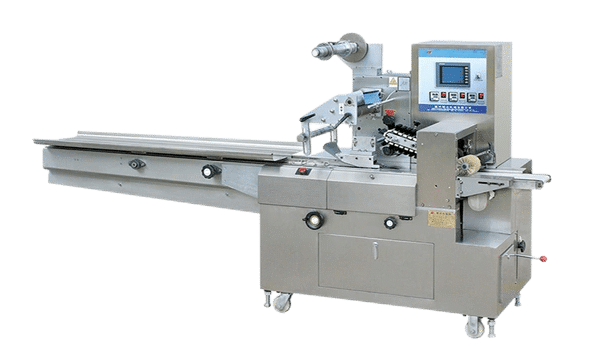

Flow-Wrapping Machines

Flow wrappers are commonly used to package biscuits. They work by continuously wrapping biscuits in packaging material. This creates sealed packs with tidy folded ends.

Flow wrappers are known for:

- High speeds – They can package a large volume of biscuits quickly.

- Versatility – They can handle biscuits of various shapes and sizes.

Because of these advantages, flow wrappers are suitable for many types of biscuits. They work by:

- Unrolling packaging film continuously from a roll.

- Detecting approaching biscuits using sensors.

- Wrapping the approaching biscuits with the moving packaging film.

- Sealing the film around the biscuits.

- Folding and cutting the film to form individual sealed packs.

Pillow-Pack Machines

Pillow pack machines are well-suited for packaging individual biscuits or small batches of biscuits. They use a single sheet of packaging material to form a pillow-shaped pack around the biscuits.

Pillow pack machines work efficiently and cost-effectively because:

- They use a single sheet of packaging material for each pack. This minimizes material usage and waste.

- They seal three sides of the pack at once, which is quicker than sealing each side individually.

- They can accommodate various biscuit sizes and shapes within the same pillow-shaped packs. This flexibility saves on production changeover time and costs.

Biscuit Cartoning Machines

Biscuit cartoning machines pack biscuits into cartons or boxes. They automatically put biscuits into the different compartments within the cartons.

Biscuit cartoning machines are typically used for:

- Family packs – Cartons containing several smaller packs of biscuits for the whole family.

- Bulk packaging – Large cartons containing many individual biscuit packs for stores and distributors.

Biscuit cartoning machines work by:

- Feeding biscuits into the machine. This can be from flow wrappers or other upstream biscuit packaging machines.

- Loaded carton feed system that supplies empty cartons to the machine.

- Placing the biscuits into their respective compartments within the carton.

- Sealing the carton once all compartments are filled.

- Discharging the filled and sealed carton.

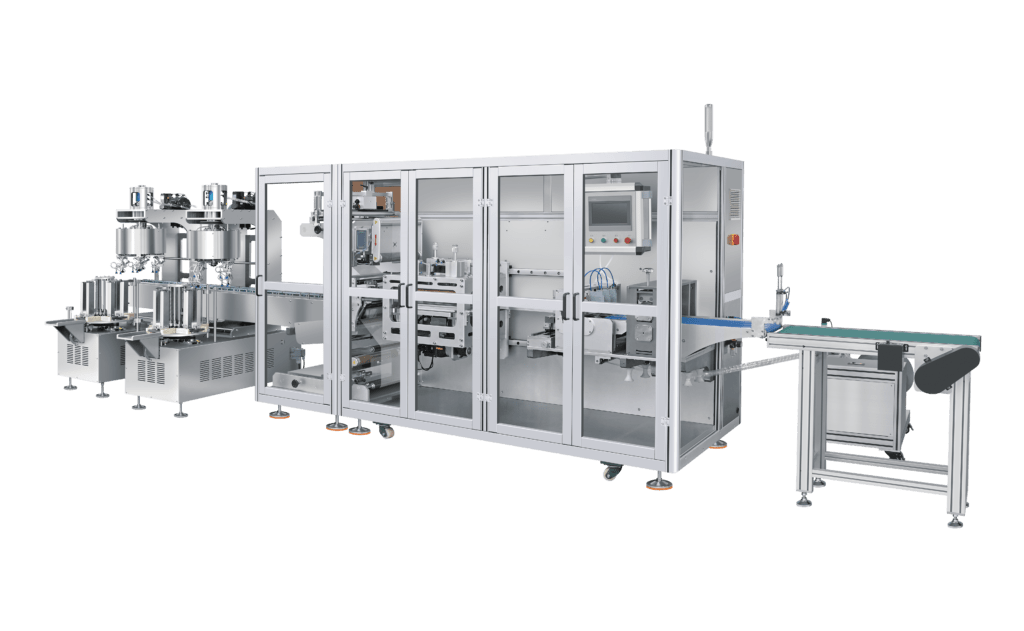

Automatic Biscuit Packaging Lines

Automatic biscuit packaging lines combine several machines into one integrated system. They can automate the entire packaging process from start to finish.

Typically, biscuit packaging lines include:

- Feeding systems to move biscuits into the line

- Biscuit packing machines like flow wrappers or pillow pack machines

- Cartoning machines to load biscuits into cartons

- Case sealers to seal outer cases

Biscuit packaging lines offer:

- High automation – Machines work together with little or no human intervention.

- Increased productivity – The lines can achieve high packaging speeds.

- Customization – The lines can be configured to suit different biscuit types and pack sizes.

Biscuits move through each stage of the line automatically:

- Biscuits are fed into the line and packed by biscuit packing machines.

- Packed biscuits are loaded into cartons by cartoning machines.

- Loaded cartons are then packed into outer cases by case sealers.

Benefits of Using a Biscuit Packing Machine

Using a biscuit packing machine brings several advantages to biscuit manufacturers. Let’s explore some of the key benefits:

Faster efficiency

The machines can package many more biscuits per minute than human workers. They reduce the need for manual labour while boosting production output.

Better quality

Manual packaging can be inconsistent. Machines ensure uniform and accurate packaging, helping keep biscuits fresher for longer. They also minimise product damage during packing.

Greater flexibility

Biscuit packing machines offer flexibility in packaging options. Manufacturers can easily adjust the machines to accommodate different biscuit sizes, shapes and packaging materials. This allows customisation to meet diverse market demands.

Cost savings

By automating packaging, biscuit packing machines reduce labour costs and improve efficiency overall. Manufacturers can save both time and money while achieving higher production volumes.

Factors to Consider When Choosing a Biscuit Packing Machine

When buying a biscuit packing machine for your production line, consider the following factors:

Speed and Output

Choose a machine with the packaging speed and capacity to meet your production needs. Different machines offer varying speeds so pick one that aligns with your goals.

Packaging Materials

Check that the machine can handle the specific packaging materials you need for your biscuit packaging, like plastic films, foils or laminates.

Flexibility and Customization Options

Ensure the machine allows for easy adjustment to package biscuits of different sizes, shapes and styles. Flexibility is key to meeting changing demands and product variations.

Ease of Operation and Maintenance

Choose a machine that is user-friendly and easy to operate. It should have a clear interface and intuitive controls. Additionally, consider the maintenance requirements of the machine, including cleaning, lubrication, and parts replacement.

Integration with Existing Production Line

If you already have a biscuit line, choose a packing machine that integrates smoothly with your existing setup in terms of conveyors, feeding mechanisms and workflow.

Common Features and Components of Biscuit Packing Machines

Biscuit packing machines consist of various features and components that contribute to their functionality. Understanding these components can help you make an informed decision when selecting a machine. The key components include:

Feeding System

The feeding system of a biscuit packing machine feeds biscuits into the packaging process. It first supplies biscuits to the packaging machine at a steady rate.

Feeding systems usually consist of:

Vibratory feeders: Trough-shaped bowls that vibrate to move biscuits into the packaging machine one by one.

Conveyor belts: Continuous belts that transport biscuits at a controlled speed into the machine.

Rotary disc feeders: Rotating discs with pockets that pick up individual biscuits and release them into the packaging machine.

The type of feeding system depends on the design and requirements of the biscuit packing machine. For example:

- Vibratory feeders are good for fragile or oddly shaped biscuits.

- Conveyor belts can handle high biscuit volumes but may damage delicate biscuits.

- Rotary disc feeders offer consistent, even feeding of biscuits into the machine.

Packaging Material Handling

Biscuit packing machines use packaging materials like plastic films or metal foils to wrap the biscuits.

The machines handle the packaging materials in this way:

First, the packaging material is supplied in a roll.

Then the machine unwinds the packaging material from the roll.

Next, the unwound packaging material is fed through the packaging process. This means:

- Guiding the material through the machine

- Positioning it correctly around the biscuits

- Sealing it to enclose the biscuits

- Cutting it to form individual packs.

The machine handles different types of packaging rolls:

- Plastic films for moisture resistance and visibility

- Metal foils for barrier properties and heat reflection

- Laminated materials for strength and printability.

Sealing Mechanism

The sealing mechanism is what closes the packaging material securely around the biscuits.

Depending on the machine, sealing can be done in different ways:

Heat sealing: Uses heat and pressure to melt and join the plastic film together. This is a common sealing method for plastic films and laminates.

Ultrasonic sealing: Uses high-frequency vibrations to fuse and seal packaging materials like plastic and foil. It generates less heat than heat sealing.

Mechanical sealing: Uses mechanical forces alone to crimp and seal packaging materials together. No heat is involved.

The type of sealing mechanism depends on:

- The packaging material used – Some materials seal better with heat while others need ultrasonic or mechanical sealing.

- The biscuit type – More delicate biscuits require less heat, suiting ultrasonic or mechanical sealing.

- Manufacturers’ preferences – Different sealing methods have varying performance, efficiency and cost implications.

Control System

The control system of a biscuit packing machine lets the operator set different parameters to precisely control the packaging process. Operators can adjust:

- Packaging speed – Depending on the production requirements, operators can set the optimal speed for the packaging machine.

- Sealing temperature – For machines using heat sealing, the temperature can be tuned to suit different packaging materials.

- Pack length – The length of each individual pack can be specified to achieve the desired biscuit count per pack.

The control system typically includes:

- A control panel or touchscreen – This displays information and allows operators to input settings.

- Sensors – To monitor functions like roll material feed, biscuit detection and pack formation.

- Programmable logic controller – This executes the programmed automation sequence based on the set parameters.

By letting operators specify parameters like speed, temperature and pack size, the control system ensures:

- Consistency – The set parameters ensure a repeatable packaging process with less variations.

- Flexibility – Easy adjustment of parameters allows the machine to package different biscuit types and sizes.

- Precision – The control system helps achieve accurate biscuit counts per pack within specified ranges.

Safety Features

Biscuit packing machines include several safety features to protect operators and prevent accidents. Common safety features are:

Emergency stop buttons – Big red buttons that immediately shut down the machine’s power supply when pressed.

Safety interlocks – Mechanisms that detect unsafe conditions and automatically stop machine operations.

Guards – Physical barriers that prevent operators from accessing dangerous areas while the machine is running.

Together, these safety features aim to:

- Protect operators – By allowing them to quickly stop the machine in emergencies and preventing access to hazardous parts.

- Avoid injuries – By detecting unsafe conditions and shutting down operations before injuries can occur.

- Comply with regulations – Safety features ensure biscuit packing machines meet occupational health and safety standards.

In addition to safety features, manufacturers also:

- Provide training and instructions – Operating and safety manuals explain how to use the machine safely.

- Conduct risk assessments – To identify any potential hazards and mitigate risks.

- Establish safety procedures – Such as lockout/tagout for maintenance.

Key Considerations for Optimal Biscuit Packaging

To ensure the best packaging results, several considerations should be kept in mind:

Proper Product Orientation

Proper orientation of biscuits within the packaging is important to ensure an attractive product presentation. Biscuit packing machines achieve this through:

- Careful handling – Biscuits are fed into the machine and transported through the packaging process in a way that preserves their desired position and arrangement.

- Alignment mechanisms – Physical guides, dividers or moulds within the machine help orient the biscuits correctly before they are wrapped or boxed. This ensures a neat, uniform final pack.

For example, flow wrappers typically have:

- V-shaped guides – These funnel biscuits into the machine and align them sideways before wrapping.

- Dividers – Separate layers of biscuits to keep them evenly spaced within the final pack.

Pillow pack machines have:

- Moulds – Pre-formed cavities that hold individual biscuits in the correct position for packaging.

Proper orientation helps provide:

- An aesthetic appearance – By arranging biscuits in an orderly manner within the pack.

- Consistency – In how biscuits are presented from one pack to the next.

- Visibility – Of biscuit designs and branding on the outer faces of packs.

Moisture and Air Control

Biscuits are sensitive to moisture, which can change their texture and flavor.

To protect biscuits from moisture and air, manufacturers should:

Use suitable packaging materials – Like plastic films and metal foils. These:

- Act as barriers to moisture and air

- Help maintain the crispness of biscuits for longer

Apply effective sealing techniques – Such as heat sealing or ultrasonic sealing. This helps create a tight seal that keeps out moisture and air.

Shelf-Life and Product Protection

Good biscuit packaging provides sufficient protection to maintain freshness and quality. Specifically, it should protect biscuits from:

Physical damage – By using robust packaging materials and careful handling procedures that avoid crushing the biscuits. This helps maintain the biscuits’ texture and appearance.

Moisture – Through moisture-resistant materials like plastic films and metal foils, as well as air-tight seals. This helps keep biscuits crisp for longer.

Light – By using opaque or dark packaging that blocks ultraviolet light. This prevents the biscuits from losing flavors andcolors.

Environmental factors – Things like temperature changes and microorganisms are blocked by packaging with good barrier properties. This helps biscuits resist spoilage.

By offering multiple layers of protection – like sealed film pouches inside cardboard boxes – biscuit packaging can:

- Extend shelf life – By shielding biscuits for longer from potential threats to freshness.

- Maintain quality – By preventing damage, moisture absorption and other degradation that affects attributes like taste and texture.

- Preserve appearance – Through protection from physical impacts and light exposure that can fade colors.

Package Aesthetics and Branding

Brand Identity – Packaging is often the first thing consumers see, making it crucial for establishing brand identity. Features like:

- Consistent use of color schemes, fonts and graphics

- A distinctive logo or icon

- Catchy taglines

help convey what the brand stands for and distinguish it from competitors. This improves recognition and recall.

Aesthetic Appeal – Attractive packaging designs that are:

- Pleasing to the eye

- Well-proportioned and balanced

- Creative yet straightforward

improve the visual appeal of biscuits, capturing consumers’ attention on shelves. This influences purchase decisions.

Product Information – Clearly displaying:

- The biscuit type and flavor

- Ingredients and nutritional information

- Manufacturer and origin details

helps consumers quickly identify whether the product meets their needs. This in turn boosts confidence in the brand.

Calls to Action – Including actions like “Share your bakery story” or “Get the full range now!” on the packaging:

- Engages consumers emotionally

- Provides a tangible next step

- Motivates them to purchase

Maintenance and Troubleshooting Tips for Biscuit Packing Machines

To keep a biscuit packing machine running smoothly, regular maintenance and troubleshooting are crucial. Consider these tips:

Thorough Cleaning and Lubrication

Clean the machine frequently to remove crumbs, dust and debris that can impact performance. Lubricate movable parts as recommended by the manufacturer to ensure easy operation.

Equipment Inspection and Part Replacement

Inspect the machine regularly for wear and tear. Replace worn parts like sealing belts or cutting blades to maintain optimal performance and packaging quality.

Machine Calibration and Adjustment

Calibrate and adjust the machine periodically to ensure accurate packaging. Check settings like sealing temperature, pack length and cutting position.

Common Issue Identification and Resolution

Train operators to identify and resolve typical problems during machine use. Issues with the sealing, feeding or cutting mechanisms, for instance, can be quickly fixed to minimize downtime.

Proper maintenance and troubleshooting can help:

- Extend the machine’s lifespan

• Increase packaging efficiency and accuracy

• Reduce unscheduled downtime

•Improve overall productivity

While no specific cleaning products are recommended, ensure any product used is approved by the manufacturer and gently cleans the machine without damaging parts. Lubricants should also be compatible with the machine’s various materials.

Safety Guidelines for Operating Biscuit Packing Machines

To operate biscuit packing machines safely, follow these guidelines:

Proper training and certification

Ensure operators undergo thorough training on how to use and maintain the machine safely. Trained personnel can handle the machine correctly and reduce accidents.

Use of personal protective equipment (PPE)

Operators should wear safety glasses, gloves, and protective clothing during machine operation and maintenance. This minimizes the risk of injury.

Effective machine guarding

Equip machines with guards covering moving parts and dangerous areas. Inspect guards regularly to ensure they are working properly.

Clear emergency stop procedures

Communicate and train operators on how to quickly stop the machine in emergencies. The machine should have big, red emergency stop buttons that are easily accessible.

Other safety precautions include:

- Lockout/tagout procedures during maintenance

- Awareness of potential hazards

- Avoidance of loose clothing and jewelry near moving parts

Frequently Asked Questions (FAQs)

What is the recommended speed for a biscuit packing machine?

Machines can operate at speeds from 100 to over 1,000 packs per minute, depending on the specific model and biscuit type. Manufacturers recommend running at a moderate speed that matches your production needs.

Can a biscuit packing machine handle different sizes and shapes of biscuits?

Yes! Modern machines are very flexible, allowing adjustments to properly package biscuits of various sizes and shapes.

How can I ensure the freshness and quality of the biscuits during packaging?

Choose moisture-resistant and air-tight packaging materials. Seal the packs properly. Together, these will create a barrier protecting the biscuits from external factors that affect freshness.

Are biscuit packing machines customizable to meet specific packaging requirements?

Yes, machines often offer optional features and adjustments to meet unique packaging requirements. Manufacturers can modify settings, change parts, or add features for customization.

What is the average lifespan of a biscuit packing machine?

It depends on factors like machine quality, maintenance and usage. With proper care, a high-quality machine can last for many years – typically 5 years or more. Regular maintenance and lubrication are key to achieving a long lifespan.

In conclusion, biscuit packing machines revolutionize the packaging process in the biscuit industry, providing efficiency, improved product quality, and customization options. By considering the factors outlined in this guide and following safety guidelines, manufacturers can choose the right machine and optimize biscuit packaging for enhanced market appeal and customer satisfaction.