Every industry that packages paste-like products — from food and beverages to pharmaceuticals and cosmetics — knows the importance of a reliable, high-speed, and precise filling machine. But if you’re new to this space or looking to upgrade, you may be wondering: what makes the perfect paste filling machine? In this article, we’ll delve into the intricacies of paste filling machines, their benefits, and why they’re a crucial component in your production line.

Types of paste filling machines

There are various types of paste filling machines available based on their technology, filling speed, and features. Understanding the different types will help you find the most suitable machine for your needs.

Serial rotor machines

Serial rotor machines fill paste one container after another using multiple nozzles. They have lower filling speeds of around 50 to 300 containers per minute. They work well for low to medium volume filling of small containers.

Parallel rotor machines

Parallel rotor machines fill multiple containers simultaneously using multiple nozzles. They have higher filling speeds of 300 to 1,000 containers per minute. They are suitable for medium to high volume filling requirements of larger containers.

Volumetric machines

Volumetric paste filling machines work by displacing a precise volume of paste into the containers using piston pumps or augers. They offer very high accuracy but tend to have lower filling speeds.

Multihead machines

Multihead filling machines use multiple filling heads that work independently and simultaneously. They can offer very high filling speeds of over 1,000 containers per minute. However, they tend to be more complex and expensive.

Liquid pouch filling machine

Premade Pouch filling machines are designed specifically for filling paste into flexible pouches. They offer high accuracy, speed, and efficiency for high volume pouch filling operations.

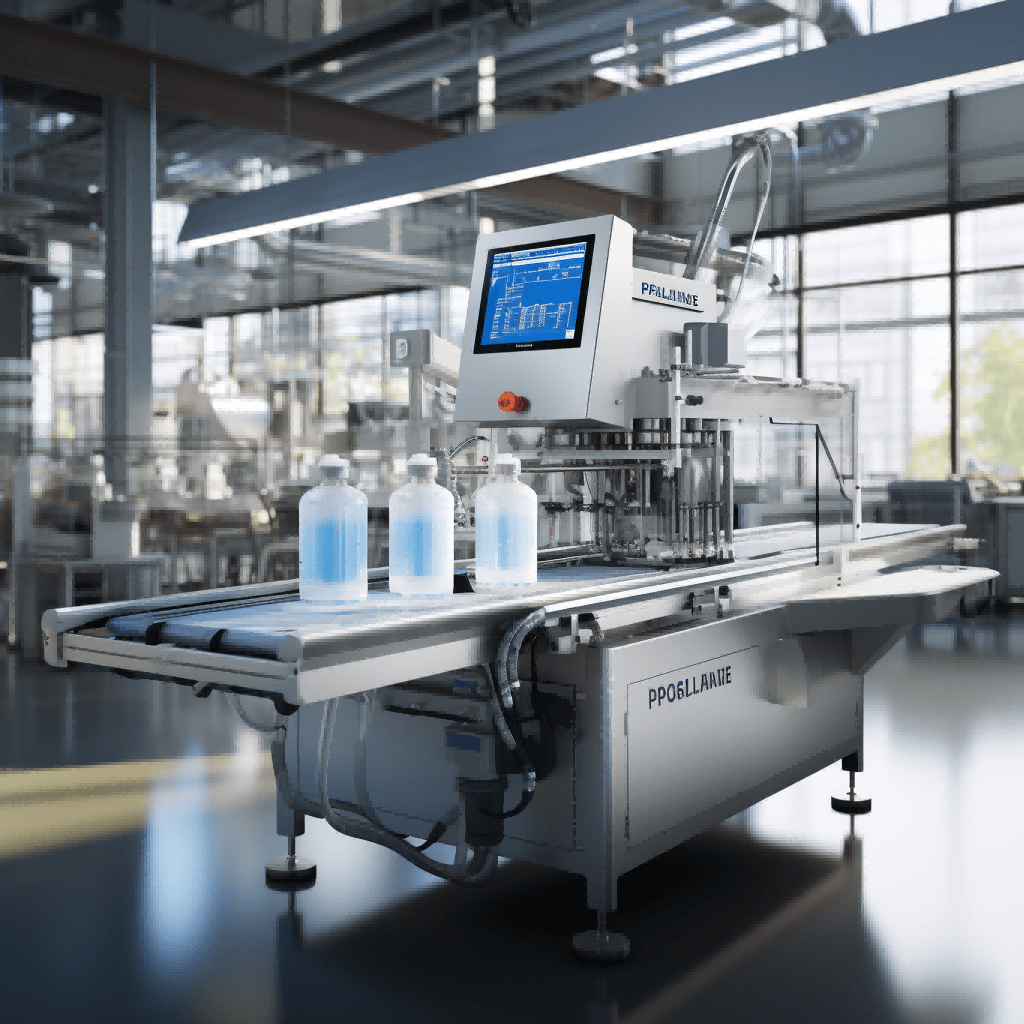

Features and Benefits of Paste Filling Machines

When purchasing a paste filling machine from filling equipment manufacturers, consider these features:

- Capacity: Make sure the machine’s capacity matches your production needs. Can it handle your required volume?

- Speed: Look at the machine’s fill rate. How many containers can it fill per minute or hour?

- Accuracy: Check the machine’s filling accuracy. Can it consistently fill containers to the desired level without over or under-filling?

- Ease of Use: The machine should be easy to operate, with a user-friendly interface and clear instructions.

- Maintenance: Ideally, the machine should be low-maintenance and easy to clean.

Paste filling machines offer a multitude of benefits that streamline operations and improve product quality:

- Efficiency: Paste filling machines automate the process of filling containers with viscous products, significantly reducing the time and manual labor involved.

- Precision: These machines offer unparalleled accuracy in filling containers to exact specifications, minimizing product waste and ensuring consistency.

- Versatility: Paste filling machines can handle a wide array of paste-like products, including food spreads, creams, gels, and more. They can also be adapted to different container types and sizes.

Working principle

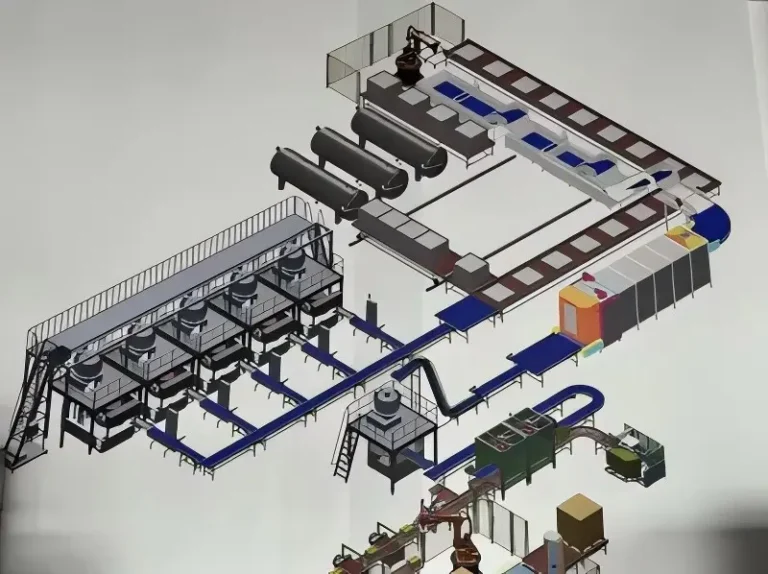

Paste liquid filling machines work on a relatively simple principle to accurately fill containers with viscous liquids. The main components and working steps are:

- Inlet hopper: The paste or liquid product is stored in a large inlet hopper at the top of the machine. This provides a constant supply of product to the filling system.

- Metered filling: The paste is metered and dispensed into the containers through precision filling heads. This can be done using various technologies like piston pumps, augers, or volumetric filling.

- Filling heads: The filling heads contain nozzles that dispense the paste into the containers. They are precisely controlled to dispense the correct fill weight or volume.

- Controls and sensors: The filling process is controlled by a programmable logic controller (PLC) and precision sensors. Sensors monitor the fill level and weigh the filled containers to ensure accuracy.

- Dispensing speed: The speed at which the paste is dispensed into the containers determines the overall filling speed of the machine. Faster filling heads provide higher output.

- Output conveyor: Once filled, the containers are transferred to an output conveyor that takes them to the next stage of the production line.

- Cleaning system: The filling machine is equipped with nozzles and spray balls to flush the system and remove dried paste from the filling heads and hoses.

That covers the basic working principle of paste filling machines in simple terms. The inlet hopper supplies the paste, the filling heads dispense the precise amount into the containers, and control systems ensure accuracy.

Applications

- • Food and beverage: Used to fill paste products like ketchup, mustard, mayonnaise, cake icing, toothpaste, and more. Commonly fills bottles, jars and pouches.

- Cosmetics and personal care: Fills creams, lotions, hair gels, lip balms, soaps and other viscous personal care products into tubes, jars and bottles.

- Chemical industry: Fills adhesives, sealants, lubricants, waxes and other industrial fluids into pails, drums and intermediate bulk containers (IBCs).

- Pharmaceutical: Ideal for filling ointments, gels and other semi-solid drugs into bottles, tubes and sachets. Ensures accurate and consistent dosage.

- Household cleaning: Fills furniture and floor polishes, shoe polishes, window cleaners and other viscous cleaners into bottles for retail sale.

- Lubrication and grease: Used to fill greases and assembly lubricants into cartridges, pails and drums for industrial and commercial use.

Cost considerations

There are several factors that influence the cost of a paste filling machine. The main factors are:

- Type – Different types of filling machines have different costs. Parallel rotor and volumetric machines tend to be more expensive than serial rotor machines. Multihead machines cost the most.

- Filling speed – Faster filling speeds require more sophisticated technology and drive costs up. Machines that fill 500 containers per minute or more tend to be significantly more expensive.

- The number of heads – Multihead machines with more filling heads cost more since each additional head adds to the cost.

- Automation level – More automated machines that require less manual intervention have a higher price tag. Fully automated lines are the most expensive.

In general, high-speed paste-filling machine costs can range from around $30,000 for a basic manual serial rotor filler to over $200,000 for a high-speed multi-head machine. Volumetric machines tend to fall in the $50,000 to $100,000 range.

Some rough cost ranges for filling machines are:

- Serial rotor: $30,000 to $75,000

- Parallel rotor: $50,000 to $150,000

- Volumetric: $50,000 to $150,000

- Multihead: $100,000 to $250,000

- Pouch filling Machine: $50,000 to $150,000

The actual cost will depend on the specifications and features of the specific machine you need. For a more accurate estimate, contact us to Get Your Free Machine ROI Calculator!

Maintenance and cleaning

It is important to follow the manufacturer’s maintenance schedule and guidelines specific to your filling machine model. In general, these are some common tips:

- Clean all parts thoroughly and regularly. This is especially important for paste-filling machines since paste can dry and solidify on moving parts. Disassemble parts that can be easily removed for thorough cleaning.

- Lubricate moving parts regularly using the recommended lubricants. Check lubrication levels and add lubricants as needed.

- Check belts and adjust the tightness as needed. Worn or loose belts can reduce filling speed.

- Check the filling volume accuracy periodically by weighing the filled containers. Adjust calibration as needed.

- Maintain air filters and air compressors that power the machine. This ensures a constant supply of clean, compressed air.

- Inspect electrical components for damage or loose connections that can cause failures. Repair or replace as needed.

For paste-filling machines, follow these additional tips:

- Clean paste handling parts more frequently since paste tends to dry and build up quickly.

- Disassemble paste pumps and check for wear and clogging. Clean or replace worn parts.

- Flush paste lines and hoses thoroughly with warm water to remove the dried paste.

- Replace or sharpen cutting tools and knives that cut paste tubes and handles.

With proper maintenance and cleaning, paste-filling machines can run reliably for many years. However, maintenance requirements will depend on the specific machine and paste product being filled. Following the manufacturer’s recommendations closely will optimize machine performance.

The Future of Paste Filling Machines: Automation and Innovation

With advancements in automation and AI, paste filling machines are becoming even more efficient and precise. Smart machines can adjust their operations in real-time to optimize performance and reduce waste. They can even predict maintenance needs, reducing downtime and increasing productivity.

- Automatic Cleaning System: A paste filling machine with an automatic cleaning system that eliminates the need for manual cleaning, saving time and reducing the risk of contamination.

- Mobile Unit: Automatic paste filling machine that is compact and easy to move, allowing businesses to use it for on-site events or in different locations.

- Customizable Nozzles: A paste filling machine that comes with customizable nozzles to accommodate different container sizes and shapes, eliminating the need for businesses to purchase multiple machines.

- Smart Integration: A paste filling machine that integrates with smart technology, allowing businesses to monitor and control production processes remotely and optimize productivity.

- Multi-Product Capability: A paste filling machine that can handle multiple types of products, including both liquids and pastes, reducing the need for separate machines and streamlining production.

- Eco-Friendly Materials: A paste filling machine made from eco-friendly materials, such as recycled plastic, to reduce the environmental impact of production processes.

- Adjustable Speeds: A paste filling machine with adjustable speeds to accommodate different production volumes and reduce the risk of overfilling or underfilling containers.

- Predictive Maintenance: A paste filling machine that uses predictive maintenance technology to detect potential issues before they cause downtime or production delays.

- User-Friendly Interface: A paste filling machine with a user-friendly interface that simplifies the operation and maintenance process and reduces the need for extensive training.

- Automated Monitoring: A paste filling machine with automated monitoring capabilities that detect and alert operators to any issues or irregularities in the filling process, ensuring quality control and reducing waste.

FAQ

Q: What is a Paste Filling Machine?

A: A Paste Filling Machine is specialized equipment used in various industries for the efficient and accurate packaging of paste-like products. These machines are designed to handle various viscosities and consistencies of pastes, ensuring precise filling and packaging.

Q: How do Different Types of Paste Filling Machines Operate?

A: Different types include volumetric machines that use piston pumps or augers, and multi-head machines that fill multiple containers simultaneously. The choice depends on the desired filling speed, accuracy, and production volume.

Q: What are the Applications of Paste Filling Machines in Various Industries?

A: Paste filling machines are widely used in industries like food and beverage (for sauces, spreads, etc.), cosmetics (for creams and lotions), pharmaceuticals (for ointments and gels), and chemicals (for adhesives and sealants).

Conclusion

Paste filling machines are an essential component in many industries, offering increased efficiency, precision, and versatility. As technology continues to evolve, we can expect to see even more innovative features in these machines, further revolutionizing the way we package paste-like products. please contact us if you have any questions

Lintyco is a pioneer and leader in automated Paste Filling Machine and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.