Cannabis packaging requires an application of multi-functional equipment that can perform multiple tasks.

For example, you’ll need a machine that can package, label, and even inspect quality.

This guide discusses aspects of cannabis packaging machines, including functioning principles, benefits, and classification criteria.

Cannabis Packaging Machine Work Process

In general, an accurate cannabis packaging machine will sort, fill, seal, check quality, and label.

However, the order in which these activities occur differs from machine to machine.

To learn how cannabis packaging equipment works, read the user handbook.

However, the typical sequence includes:

- The machine is filled with packaging materials and the product to be packaged.

- The packing step involves filling the package with the desired amount of cannabis product. This can be accomplished using a filling mechanism like a hopper or a filling head.

- After you’ve filled the package, seal it to secure the product and avoid contamination. This method often involves heat sealing or taping.

Attention:

- Cannabis packing machines may have additional functions like labeling and coding. Labeling involves adding information to a package, such as the product name, manufacturer, and any necessary warning labels.

- Coding can include adding an expiration date or batch number to a package. These elements could be added into the packaging process at this point.

- Cannabis packaging machines may incorporate a weighing element to ensure accurate product quantity. The package is weighed to confirm it is within the stipulated weight or capacity.

- Once filled, sealed, and labeled, the package is ready for delivery or storage.

Why Invest Packaging Equipment for Cannabis

Investing in advanced packaging equipment for cannabis products offers numerous advantages that can significantly benefit your business:

- Improved Efficiency: High-quality packaging equipment can enhance the efficiency of your packaging process. This allows you to package more cannabis products in less time, reducing waste and increasing productivity while lowering costs.

- Enhanced Product Quality: Superior packaging equipment protects your products from damage during the packaging process, ensuring they reach customers in optimal condition. This improves customer satisfaction and loyalty.

- Increased Compliance: Packaging equipment that meets industry standards and regulations ensures your products are properly labeled, helping you stay compliant with local and federal laws.

- Enhanced Brand Image: Using high-quality packaging equipment can boost the perceived value of your cannabis products, enhancing your brand image. This helps you stand out in a competitive market and attract more clients.

- Increased Sustainability: Packaging equipment designed to minimize waste and reduce environmental impact can improve your business’s sustainability. This is particularly important in the cannabis industry, where consumers increasingly seek products produced sustainably and responsibly.

- Customization Options: Equipment that offers customization options allows you to create packaging tailored to your specific needs and branding, helping differentiate your products from competitors and strengthening your brand identity.

- Enhanced Security: Packaging equipment with features like child-resistant packaging or tamper-evident seals improves product security, protecting against unauthorized access. This is crucial in the cannabis industry, where strict regulations often require specific security measures.

- Improved Safety: Equipment designed with safety in mind reduces the risk of workplace accidents and injuries, enhancing overall business safety and protecting employees.

- Better Inventory Management: Advanced packaging equipment can include features that help track and manage inventory more effectively, reducing the risk of stockouts or overstocking and ensuring a smoother supply chain.

- Increased Automation: Automated packaging equipment can streamline your operations, reducing the need for manual labor and minimizing human error. This leads to more consistent product quality and further cost savings.

By investing in better packaging equipment, you can ensure your cannabis products are efficiently, safely, and attractively packaged, ultimately benefiting your business in multiple ways.

Types of Packaging Machine Line for Cannabis

The cannabis industry uses a variety of packaging machinery, including:

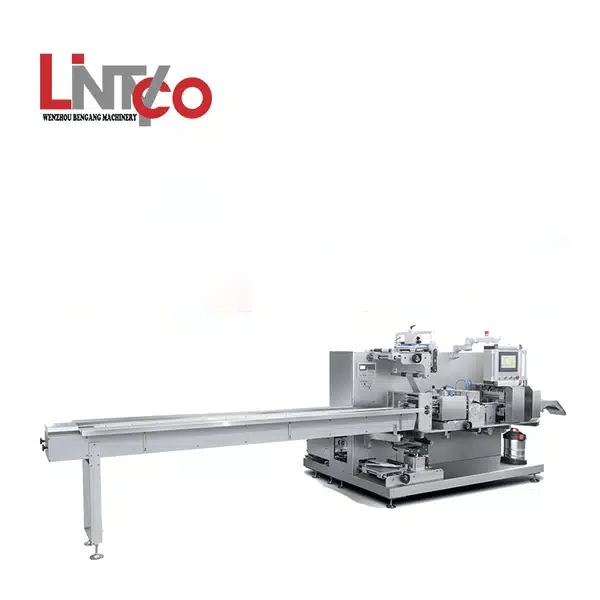

Flow Wrap Machines: These are used for packaging cannabis in small quantities. Flow wrap machines wrap cannabis products in a continuous roll of flexible film, providing a protective covering.

Vertical Form Fill Seal (VFFS) Machines: VFFS machines exist in several configurations. You can use the VFFS machine to package cannabis buds, edibles, and concentrates.

In most cases, a roll of flexible film is used to form a pouch, which is then filled with the product and sealed.

Auger Fillers: These machines are used to fill containers with dried cannabis products like flower and concentrates. They use a screw-like mechanism to precisely pour the product into containers.

Capping Machines: Capping machines secure lids or caps to cannabis product containers. They are widely used to seal bottles or jars with cannabis tinctures, oils, and other liquids.

Cartoners: A cartoner is a machine for packaging cannabis products in boxes or cartons. They can be used to package a variety of items, such as cannabis buds, edibles, and concentrates.

Case Packers are machines that package things in cases or cartons.This means that you can employ case packers to package cannabis items such as edibles, concentrates, and buds.

Shrink Wrap Machines: These are used to wrap things in a layer of shrink wrap film. The film is heated, shrinking around the product.

As a result, it provides a tight and secure seal. Shrink wrap machines can be used to package a wide range of cannabis goods, including edibles, pre-rolled joints, and concentrates.

Pouch Fill and Seal Machines: These machines are used to fill pouches with a wide range of items, such as cannabis buds, edibles, and concentrates. They employ a roll of flexible film to make a pouch, which is then filled with the goods and sealed.

Factor For Buying Cannabis Packaging Machine

There are numerous factors that should be taken into account prior to investing in cannabis packaging apparatus, including:

- The cannabis product to be packaged: Various machines may be more appropriate for various products, such as edibles or dried flowers.

- Dimensions and form of the cannabis product package: Verify that the machine can accommodate the package’s size and shape. A machine with a higher capacity or faster pace may be necessary if you have a high volume of cannabis products to package.

- Cannabis product quantity: Determine the quantity of product that must be packaged and select a machine with the requisite capacity.

- Support and maintenance: Settle for a cannabis packaging machine that is effortless to operationalize.

Additionally, guarantee that it is backed by a dependable manufacturer or supplier that can offer continuous support and assistance as required.

- Budget: Establish your budget and select a cannabis packaging machine that is compatible with it.

- User-friendliness: Opt for a cannabis packaging machine that is effortless to operate. This will guarantee that your personnel will not incur training expenses.

How to Maintain Cannabis Packaging Equipment

Proper maintenance and cleaning of a cannabis packaging machine are crucial to ensure it operates efficiently and effectively. The specific maintenance and cleaning requirements will vary depending on the type of machine and the manufacturer’s recommendations.

- Follow the manufacturer’s instructions: Carefully read and follow the manufacturer’s instructions for operating and maintaining the machine. This may include guidelines for cleaning and lubricating the machine, as well as any other maintenance tasks.

- Regularly clean and lubricate the machine: Keeping the machine clean and properly lubricated helps ensure smooth and efficient operation. Use noncorrosive materials like dish soap, warm water, and isopropyl alcohol for cleaning.

- Perform regular inspections: Regularly inspect the machine for any wear or damage and address any issues as needed. This may involve replacing worn parts or repairing damaged components.

- Calibrate the machine regularly: Regular calibration ensures that the machine accurately packages cannabis products, maintaining product consistency and quality.

- Follow proper safety protocols: Always follow proper safety protocols when operating and maintaining the machine to prevent accidents or injuries. This includes wearing personal protective equipment (PPE) and following specific procedures for handling emergencies.

- Use proper cleaning techniques: For thorough cleaning, use an air nozzle with low pressure to blow off any loose product that has accumulated on the machine, and remove the forming tube to clean it separately.

- Implement a maintenance schedule: Establishing a regular maintenance schedule helps in tracking and performing necessary maintenance tasks, ensuring the longevity and reliability of the machine.

Conclusion

At Lintyco, we have many cannabis packaging machines and equipment for your specific needs. Whether you need semi-automatic or fully automatic cannabis packaging machine, there is a perfect equipment for your business.

So, what type of cannabis packaging machine is best for your business? That answer depends on the products you are looking to package and the level of automation you need.

If you are unsure which machine would be a good fit for your company, contact Bengang Machine.

At Bengang Machinery, we can help you find the perfect machine for your needs. We have a wide selection of machines and knowledgeable staff who can answer any questions you may have about selecting the right packaging machine for your cannabis business.

Contact us today to get started!

Reference Resources

Al‐Hamdani, M., Joyce, K. M., Park, T., Cowie, M. E., & Stewart, S. H. (2020). Cannabis packaging: An opportunity for facilitating informed decisions. the Journal of Consumer Affairs/the Journal of Consumer Affairs, 55(3), 1150–1168.

Pepper, J. K., Lee, Y. O., Eggers, M. E., Allen, J. A., Thompson, J., & Nonnemaker, J. M. (2020). Perceptions of U.S. and Canadian Cannabis Package Warnings Among U.S. Adults. Drug and Alcohol Dependence, 217, 108275.

Goodman, S., Leos-Toro, C., & Hammond, D. (2019). The impact of plain packaging and health warnings on consumer appeal of cannabis products. Drug and Alcohol Dependence, 205, 107633.