Enter the caramel wrapping machine—a revolutionary tool designed to wrap caramels quickly and precisely, ensuring product quality while saving time and resources. Whether you’re a confectionery manufacturer or a small business owner looking to scale up, understanding how these machines work and their key benefits can be a game-changer for your business.

Benefits of Using a Caramel Wrapping Machine

Implementing a caramel wrapping machine offers several advantages:

Increased Output

Traditional hand-wrapping is time-consuming and labor-intensive. A caramel wrapping machine can wrap hundreds of pieces per minute, dramatically increasing your production speed and output.

Hygienic Handling

Automated machines reduce the amount of human contact with the product, which enhances the sanitary conditions of your production line, an essential factor for food safety compliance.

Cost-Effective

Though the initial investment may seem high, the long-term savings from reduced labor costs, minimized waste, and faster production times are significant. Plus, improved efficiency means you can scale your operations without proportionally increasing labor expenses.

Appealing Packaging

Machines can produce uniform and attractive packaging, enhancing product presentation and marketability.

Consistent Quality

Each caramel is wrapped with uniform precision. This consistency not only enhances the product’s visual appeal but also ensures it stays fresh longer, boosting its shelf life.

Safety

A caramel wrapping machine will enhance the safety of your operators. Also, with automatic versions, it will stop the wrapping process should it detect malfunctions.

How Caramel Wrapping Machines Operate

The operation of a caramel wrapping machine typically involves several key steps:

- Preparation: Ensure the machine is clean and connected to a caramel processing unit for a continuous supply of products.

- Feeding: The machine receives caramel pieces and wrapping film simultaneously, ready for the wrapping process.

- Wrapping: Caramel pieces are fed into the wrapping area where the machine wraps them using various methods (heat, glue, or friction) to create an airtight seal. This process is automated, allowing for high-speed production.

- Discharge: Once wrapped, the finished products exit the machine for packaging or further processing.

Types of Caramel Wrapping Machines

Caramel wrapping machines come in various forms, catering to different production needs:

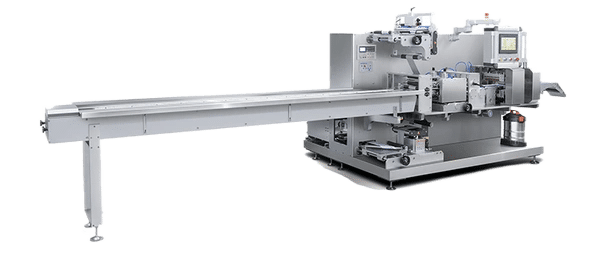

- Flow Wrapping Machines: These are versatile and suitable for wrapping candies, including caramels, in a continuous flow. They are often more affordable and can wrap multiple products simultaneously.

- Double Twist Wrapping Machines: Ideal for products like Werther’s Originals, these machines twist the ends of the wrapping material to secure the caramel inside. They tend to be more complex and are typically used for higher production rates.

- Semi-Automatic Machines: For smaller operations, semi-automatic machines allow operators to load the caramel manually, which is then wrapped automatically. This can be a cost-effective solution for businesses scaling up production.

Considerations When Selecting a Caramel Wrapping Machine

When choosing a caramel wrapping machine, several factors should be considered:

- Production Capacity: Determine the output required (pieces per minute) to meet demand. Machines can vary significantly in speed.

- Wrapping Material Compatibility: Ensure the machine can handle the desired wrapping materials, such as cellophane, wax paper, or composite films.

- Hygiene Standards: Machines should be made from materials like stainless steel for easy cleaning and corrosion resistance, ensuring compliance with food safety standards.

- Cost: Prices can range widely based on features and automation levels, from a few thousand dollars for basic models to tens of thousands for high-capacity machines.

- Integration with Other Equipment: Consider how the wrapping machine will fit into your existing production line, including compatibility with caramel cooking machines, sorting machines, and packaging systems.

Frequently Asked Questions About Caramel Wrapping Machines

1. Can caramel wrapping machines handle different types of packaging material?

Yes, most modern caramel wrapping machines are designed to work with a variety of materials, such as wax paper, cellophane, and foil. Some models even have settings for different thicknesses and material properties, making it easy to switch between materials based on your production needs.

2. What is the average production speed of a caramel wrapping machine?

The production speed of caramel wrapping machines can vary depending on the model. However, industrial-grade machines typically range from 100 to 500 pieces per minute, which is a significant improvement over manual wrapping.

3. How much does a caramel wrapping machine cost?

The cost of a caramel wrapping machine depends on its size, capacity, and features. Entry-level machines can start at around $10,000, while high-end, fully automated machines with additional features might cost upwards of $100,000. The price also varies depending on the manufacturer and customizations needed.

4. What maintenance is required for caramel wrapping machines?

Like any machinery, regular maintenance is necessary to keep your caramel wrapping machine running efficiently. Routine checks for wear and tear on belts, blades, and rollers, along with lubrication of moving parts, are essential. Many machines come with maintenance manuals and easy-to-replace parts, ensuring minimal downtime.

5. Can a caramel wrapping machine be integrated into an existing production line?

Yes, Lintyco Pack designs caramel wrapping machines with easy integration in mind. You can connect them to other systems in your production line, such as cutting machines, caramel-making machines, counting machines, sorting machines, and packaging stations, to streamline your workflow.

Conclusion

In the candy industry where time is money and consistency is crucial, investing in a caramel wrapping machine can significantly enhance your operations. By automating the packaging process, you’ll save on labor costs, boost production efficiency, and maintain the quality of your product—leading to happier customers and a healthier bottom line.

Whether you’re a small artisan candy maker or a large-scale manufacturer, the right caramel wrapping machine will prove to be an invaluable asset. You can take a look at How to start a candy business .It’s time to explore this game-changing technology and position your business for success in a competitive market.