Are you curious about the process behind packaging cartoons? Do you want to know how cartoon machines work? Look no further! In this comprehensive FAQ guide, we will explore the world of cartoon packaging machines and answer commonly asked questions. From understanding the basics to discovering the benefits and types of cartoon packaging machines, we’ve got you covered. So, let’s dive into the fascinating world of cartoon packaging machines together!

Introduction

Cartoons bring joy and entertainment to people of all ages. But behind the scenes, packaging helps make sure these cartoons reach customers in perfect shape. Special cartoon packaging machines design the packaging process to work automatically. This makes the process efficient and produces packages the same way each time. The packaging machines aim to reduce human errors in the packaging of cartoons.

What is a Cartoon Packaging Machine?

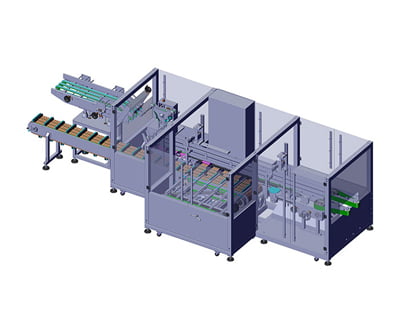

Cartoon packaging machines are mechanical tools that pack cartoons in a good way.These machines make the packaging process better by doing tasks automatically like forming cartons, filling them , sealing, putting on labels and checking quality. Many companies that make and send cartoons of different kinds use these machines a lot. They help speed up the packaging process and make it more consistent with fewer mistakes compared to humans doing the work by hand. Cartoon packaging machines improve the productivity, efficiency and cost-effectiveness of packaging operations for cartoon manufacturers and distributors.

How Does a Cartoon Packaging Machine Work?

Cartoon packaging machines use different kinds of parts like mechanical, electrical and air parts to do the work. The packaging process generally has these steps:

- The machine folds and sticks together cardboard sheets to form the carton.

- The cartoons are placed into the cartons either manually or automatically.

- The machine seals the cartons shut using tape or glue. It may also put on labels or barcodes for identification.

- The machine checks the packaging for any problems or differences, making sure the cartoons meet quality standards.

- If needed, the machine can stack the cartons on pallets ready for transport.

Benefits of Using Cartoon Packaging Machines

Using cartoon packaging machines offers several advantages:

- They save time and work – The machines automate packaging tasks so they are much faster and require less human labor compared to manual packaging.

- The packages are consistent – The machines package cartoons in the same way every time which ensures consistent quality and accuracy of the packages. There are fewer mistakes.

- Lower costs – Since the machines reduce the amount of human labor needed for packaging, companies save on wages and other labor costs. This improves their profitability.

- Better protection – The packages produced by the machines are secure and reliable which provides better protection for the cartoons during shipping and storage. The cartoons are less likely to get damaged.

Types of Cartoon Packaging Machines

Automatic Cartoon Packaging Machines:

- Fully automated – All packaging tasks are done automatically by the machine using sensors, conveyor belts and robotic arms. Little or no human intervention is needed.

- High-speed operations – Since there is no manual labor involved, these machines can operate at high speeds of up to several hundred packages per minute.

- Suitable for large-scale production – The high throughput and fully automated nature makes these machines ideal for companies with high packaging volumes.

Semi-Automatic Cartoon Packaging Machines

- Combine manual and automatic operations – While some tasks like loading cartons are done manually, other functions like sealing and labeling are automated.

- Versatile and adjustable – The machines can be adjusted to accommodate different carton sizes and shapes. They are more flexible than fully automatic machines.

- Medium packaging speed – The production speed is medium as it depends partly on human loading/unloading speeds.

- Suitable for medium production volumes – These machines are suitable for companies with medium packaging volumes that do not require the high throughput of automatic machines.

Factors to Consider When Choosing a Cartoon Packaging Machine

When selecting a cartoon packaging machine, consider the following factors:

- Required Production – The most important factor is the packaging speed and volume you need to meet your production demands. Make sure the machine you choose has the capacity for your needs.

- Compatible Carton Sizes – The machine must be able to package cartoons of the sizes and shapes you use. Check the specifications to confirm its carton compatibility.

- Flexibility and Adjustability – Opt for a machine that is adjustable to accommodate different carton sizes and formats. The more flexible, the better.

- Quality and Durability – Choose a machine from a reputable brand that is known for high quality and durability. This ensures long lifespan and minimal breakdowns.

- After-Sales Support – Consider the availability of spare parts, technical support and maintenance services from the manufacturer when selecting a machine. Good after-sales support adds value.

- Ease of Use – Simple, user-friendly machines tend to have a lower error rate and require less training for operators. This improves efficiency.

- Cost – Compare prices from different suppliers but do not compromise too much on quality to get the lowest cost. A balance is important.

Step-by-Step Process of Packaging Cartoons

- Carton Formation – The machine folds flat cardboard sheets to form cartons of the desired size and shape. It seals the carton edges to hold the shape.

- Cartoon Loading – Either manually or automatically, cartoons are loaded into the formed cartons. The machine ensures the cartoons are correctly positioned within the cartons.

- Sealing and Labeling – The machine applies adhesive tape or hot glue to seal the carton flaps. It may also apply barcodes or text labels for product identification and tracking.

- Quality Inspection – The machine checks the quality of the packaging to identify any defects such as poorly sealed cartons or misaligned cartoons. Defective packages are discarded.

- Palletizing (optional) – If required, the machine stacks the sealed cartons onto pallets in an organized manner ready for storage and shipping.

Common Challenges and Troubleshooting Tips

While cartoon packaging machines are efficient, they may encounter challenges. Here are some common issues and troubleshooting tips:

- Carton Jams – If cartons become stuck in the machine, stop the machine immediately. Gently remove the jammed carton. Check that cartons are properly aligned before restarting. Also ensure carton guides are clean and positioned correctly.

- Seal or Label Defects – Inspect the adhesive application or labeling mechanism for problems. Issues like dried glue, clogged nozzles or misaligned labels need to be fixed. Adjust parameters or replace worn parts.

- Misaligned Cartons – Verify that cartons are loaded properly and in the correct orientation within the machine. Check that carton guides, sensors and conveyor belts are functioning properly and adjusting alignment as required. Also ensure carton dimensions match machine settings.

- Electrical Issues – Check for loose wires, blown fuses or tripped circuit breakers. Inspect electrical components like motors, sensors and switches for signs of damage or wear. Problems left unaddressed can cause machine downtime.

- Mechanical Wear and Tear – Over time, parts like belts, gears, rollers and chains may show signs of excessive wear. Replace or repair worn parts to restore proper machine functioning. Conduct routine maintenance checks to catch issues early.

Safety Guidelines for Operating Cartoon Packaging Machines

- Read and follow the manufacturer’s safety instructions and operating manual closely.

- Wear personal protective equipment like safety glasses, gloves, and protective clothing at all times while using the machine.

- Keep the work area tidy and organized to avoid trip hazards and accidents.

- Inspect the machine regularly for signs of wear, damage or malfunction and fix issues promptly.

- Only trained and authorized personnel should operate the machine. Untrained users can pose a safety risk.

- Never reach into the machine while it is running or attempt to clear jams without following lockout procedures.

- Always disconnect power to the machine before performing maintenance or repairs.

- Use proper lockout/tagout procedures when servicing the machine to prevent accidental restarting.

- Keep emergency stop buttons clearly visible and accessible. Know how to use them quickly.

- Maintain and lubricate the machine according to the manufacturer’s schedule to avoid mechanical issues.

- Report any safety hazards, injuries or incidents to your supervisor immediately.

Future Trends in Cartoon Packaging Machine Technology

The future of cartoon packaging machine technology is promising. Some emerging trends include:

- Use of AI and machine learning – Algorithms can analyze data from the packaging process to optimize settings, improve efficiency, spot defects early and reduce errors. This leads to higher performance and quality.

- Increased automation and robotics – Advanced robots and automated systems are being developed to maximize the automation of packaging tasks. This significantly increases production speed and throughput.

- Focus on sustainability – There is more focus on using recycled and recyclable packaging materials as well as more eco-efficient packaging processes. Sustainable packaging machine options are emerging.

- Integration of IoT and Industry 4.0 – Connecting machines to the Internet of Things enables real-time data collection, remote monitoring and control, predictive maintenance and traceability of packages. This paves the way for Industry 4.0 benefits.

Conclusion

cartoon packaging machines provide packaging benefits that are critical for cartoon manufacturers and distributors. With proper research, machine selection and safety protocols, companies can maximize the advantages these machines offer.

The key takeaway is that cartoon packaging machines, while complex, can significantly improve packaging operations when implemented correctly. With automation, reliability and enhanced safety, they help cartoon brands increase efficiency and protect their products.