In this article, we will dive deep into the world of coffee bag materials. We’ll explore the types of materials commonly used for coffee bags, the importance of sustainability, and how choosing the right packaging can affect your coffee brand. As eco-consciousness grows, the coffee packaging industry is evolving. Whether you’re a small roaster or a large coffee company, understanding the materials behind your coffee bags can make a significant difference in protecting both your product and the environment.

What Material is Used for Coffee Bags?

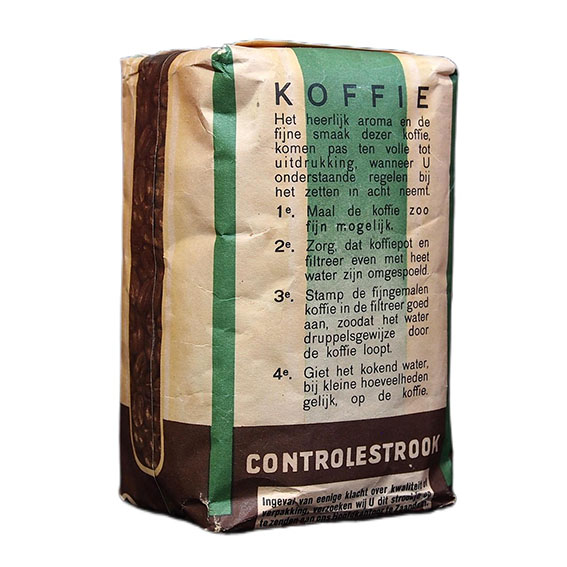

Coffee bags are made from a range of materials, each chosen based on the desired properties such as freshness retention, durability, and protection from external elements. Coffee bean bag material typically consists of multi-layered films or paper that is coated or laminated with plastics. Some materials also incorporate a layer of aluminum foil for enhanced barrier protection.

Plastic is widely used due to its flexibility and ability to provide an airtight seal, but sustainability concerns have led to the exploration of alternative materials, including biodegradable options. Understanding the material type is crucial in ensuring the coffee’s freshness, quality, and shelf life.

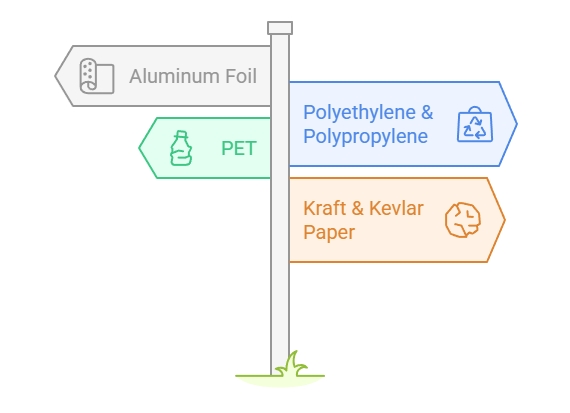

Common materials for coffee bags include the following:

Aluminum foil: Aluminum foil bags are the most widely used material in coffee packaging because of their excellent barrier properties, which can effectively prevent the entry of oxygen, moisture and light, thereby prolonging the freshness of coffee.

Polyethylene (PE) and polypropylene (PP): These plastic materials have good antioxidant, moisture-proof and wear-resistant properties, and are low in cost, but their environmental friendliness is poor and they are not easy to degrade.

Polyethylene terephthalate (PET): PET materials are widely used in coffee packaging due to their good barrier properties and recyclability, especially as inner layer materials in multi-layer structures.

Kraft paper and Kevlar paper: These paper-based materials are environmentally friendly and biodegradable, but their moisture-proof properties are relatively weak, and additional plastic coatings are usually required to improve their performance.

Bioplastics (such as PLA): PLA is a bioplastic made from renewable resources such as corn starch. It has good antibacterial and biodegradable properties, but its barrier properties are not as good as metal or composite materials.

Composite materials: such as multi-layer composite structures such as PET/AL/PE or BOPP/AL/PE, which improve barrier properties and durability by combining the advantages of different materials.

Natural fiber materials: such as sacks and cotton bags, which are environmentally friendly and biodegradable, but have strong air permeability and may not be suitable for long-term storage of coffee.

Eco-Friendly Coffee Bag Materials

As consumers become more environmentally conscious, eco-friendly packaging has taken center stage in many industries, and coffee packaging is no exception. There are various eco-friendly coffee bag materials that not only protect the product but also reduce environmental impact. These include compostable films, recyclable laminates, and plant-based materials like cornstarch or biodegradable plastics.

One popular choice is recyclable coffee packaging, which allows consumers to dispose of the bags in an environmentally responsible manner. Brands that embrace sustainable packaging often find they can appeal to eco-conscious buyers, helping to strengthen their brand identity while contributing to environmental preservation.

How Are Coffee Bag Materials Produced?

The production process of coffee bag materials involves several steps. First, the raw materials, whether paper, plastic, or foil, are sourced and processed. Coffee bag material production starts with creating the base film or paper, which is then coated with layers of plastic or foil to form a protective barrier. This process ensures that the coffee beans inside remain fresh, while the outer layers provide a printable surface for branding.

The production process is a blend of advanced manufacturing techniques, where precision is required to achieve the perfect balance between durability and barrier protection. Manufacturers must also ensure the materials meet food-grade safety standards to prevent contamination. The overall goal is to ensure the coffee remains flavorful while minimizing waste and energy consumption in the production process.

Designing Custom Coffee Bag Material for Branding

When it comes to designing custom coffee bag material for branding, there’s more to consider than just the aesthetics. The material chosen must be compatible with the printing process, whether it’s digital printing, flexographic printing, or another method. These bags need to display your logo, product name, and other details, while still serving their functional role of preserving the coffee’s freshness.

Branding through customized packaging can make a significant impact on consumer behavior, as a well-designed coffee bag can enhance product visibility and appeal. Brands often opt for custom designs that reflect the unique nature of their coffee offerings, such as using eco-friendly materials to align with the company’s sustainability mission.

Comparing Plastic vs Paper Coffee Bag Materials

The debate between plastic vs paper coffee bag materials has been ongoing for years. On one hand, plastic offers durability, flexibility, and airtight sealing capabilities. However, plastic coffee bags are often criticized for their environmental impact. On the other hand, paper bags are considered more sustainable and are biodegradable, but they might not offer the same level of protection against moisture and air.

When selecting between these two materials, coffee roasters need to balance cost, sustainability, and product preservation. Some brands opt for a hybrid solution that combines both paper and plastic to get the best of both worlds – an eco-friendly outer layer with a protective inner plastic layer.

Best Practices for Storing Coffee Bag Materials

Proper storage of coffee bag materials is essential to maintain their quality and ensure that they are in good condition when used for packaging. Best practices for storing coffee bag materials include keeping them in a dry, cool environment to prevent the materials from degrading. Excess moisture or heat can compromise the material’s strength, making it less effective for sealing.

In addition, coffee packaging should be stored away from direct sunlight to prevent degradation of the outer layer. Maintaining the integrity of the materials ensures the final product will properly protect the coffee beans inside.

Advanced Printing Methods for Coffee Bag Materials

Advanced printing methods for coffee bag materials help brands make a lasting impression on consumers. The most popular methods include flexographic printing, digital printing, and rotogravure printing, each offering unique advantages depending on the scale and complexity of the design.

Flexographic printing is one of the most common methods used for packaging because it offers high-quality prints at a lower cost for larger runs. Digital printing, on the other hand, provides a more versatile and detailed design option, making it a popular choice for smaller batches or custom orders. These printing methods play a crucial role in elevating a coffee brand’s visual identity and ensuring packaging consistency across products.

How to Find Reliable Coffee Bag Material Suppliers

Finding reliable coffee bag material suppliers is key to ensuring quality and consistency in your packaging. When sourcing materials, coffee roasters should look for suppliers with a proven track record of delivering high-quality coffee bag materials that meet food safety standards.

Reliability is also an important factor. Suppliers should offer on-time deliveries, transparent communication, and quality control processes that ensure the materials meet your expectations. When possible, it’s also beneficial to look for suppliers who provide sustainable packaging solutions, as this aligns with growing consumer demand for eco-friendly options.

Sustainability in Coffee Bag Materials: What’s Next?

The future of coffee bag materials lies in sustainability. As environmental concerns rise, more coffee brands are adopting recyclable and compostable packaging materials. Innovations in materials, such as biodegradable plastics and plant-based laminates, are paving the way for more sustainable options that help reduce waste and pollution.

Moving forward, coffee roasters and packaging companies must collaborate to create sustainable, economically viable packaging solutions that meet both environmental standards and consumer demands. With continued innovation, the coffee packaging industry will evolve to become more eco-conscious while still delivering fresh, high-quality coffee to consumers.

Eco-Friendly Coffee Bag Material Packaging Solutions From Lintyco Pack

As the demand for eco-friendly coffee bag material packaging solutions continues to grow, coffee companies are turning to materials that are both functional and environmentally responsible. These include compostable coffee bags, recyclable packaging, and materials made from renewable sources.

Some brands are exploring innovative packaging options like plant-based bags made from materials such as cornstarch or sugarcane. These alternatives offer the same benefits as traditional plastic but with far less environmental impact. By choosing eco-friendly solutions, brands not only reduce their carbon footprint but also appeal to a growing segment of environmentally conscious consumers.

Lintyco Pack has invested in environmental protection for more than 20 years. Therefore, we pay more attention to the packaging details of environmentally friendly materials than other companies. If you are interested in coffee bag packaging machines, you can click it and read the following articles for reference.