CPM Wolverine Proctor

CPM Wolverine Proctor, renowned for its innovative approaches tailored to customer needs, has pioneered the JetTube air handling technology for the processing industry. This technology is now indispensable in the processing of a wide range of food, chemical, and textile products. Proctor & Schwartz was the first manufacturer to apply the principle of forced convection drying across various industries. Their commitment to innovation has consistently benefited their clients.

The company’s international business personnel, manufacturing capabilities, and extensive global after-sales support network ensure that clients everywhere can access CPM Wolverine Proctor’s services. With over two centuries of experience, they have become a benchmark in the food, tobacco, and chemical equipment manufacturing sectors. Their excellence in heat treatment process design, grain production, and snack equipment packaging keeps them at the forefront of processing technology.

The (SCF) Single Conveyor Dryer/Cooler supplied by CPM is the most widely used continuous dryer in the world, and for good reason. This is due to years of production experience, bringing together carefully selected fans, heating systems, conveyors, chain plates, and other equipment to meet your production needs.

Application of Pet Food Dryer

Baked pet food comes in a variety of shapes and sizes. Therefore, pet food manufacturers need high quality equipment that is systematically integrated. CPM Proctor has world-class processing equipment and decades of experience in pet food mixing, moulding and baking to deliver the best solutions for customers.

Additionally, integration with the Lintyco packaging production line enables direct product delivery to distributors, significantly boosting sales.

Lintyco is a pioneer and leader in automated Pet Food Filling Machines and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.

Benifit & Feature

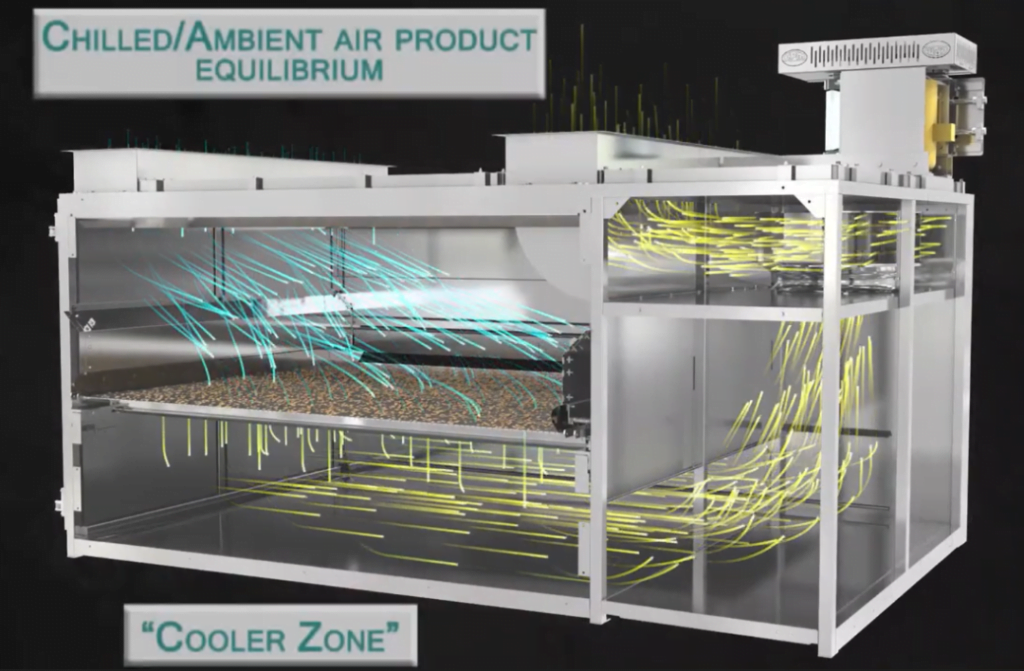

Maximum Consistency: Multi-zone temperature control with adjustable airflow and temperature control provides maximum thermal efficiency and gentle drying,. Prevents product grading.

Uniformity: Airflow and temperature distribution ensures better uniformity of the final product.

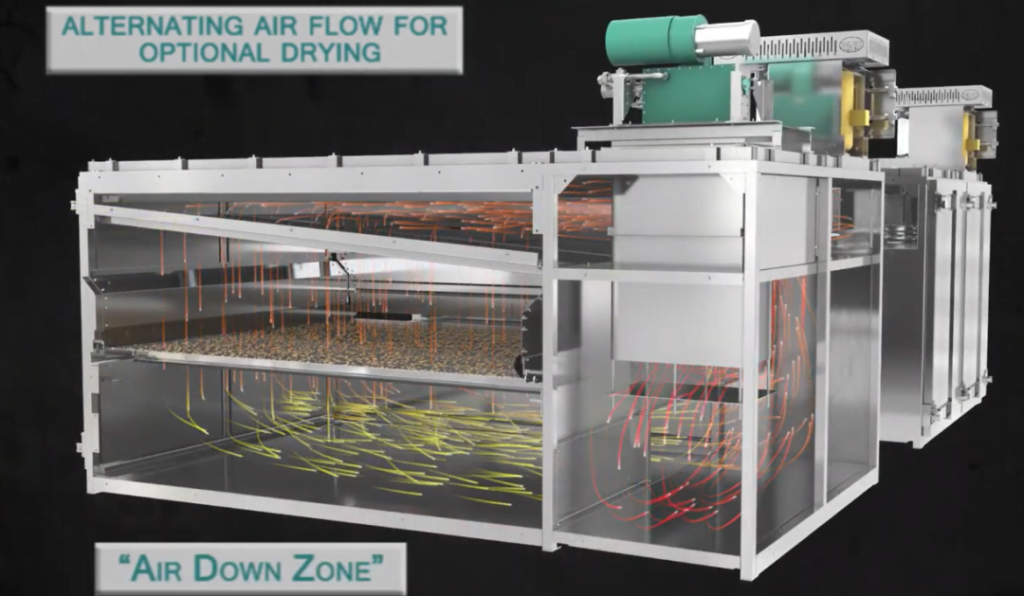

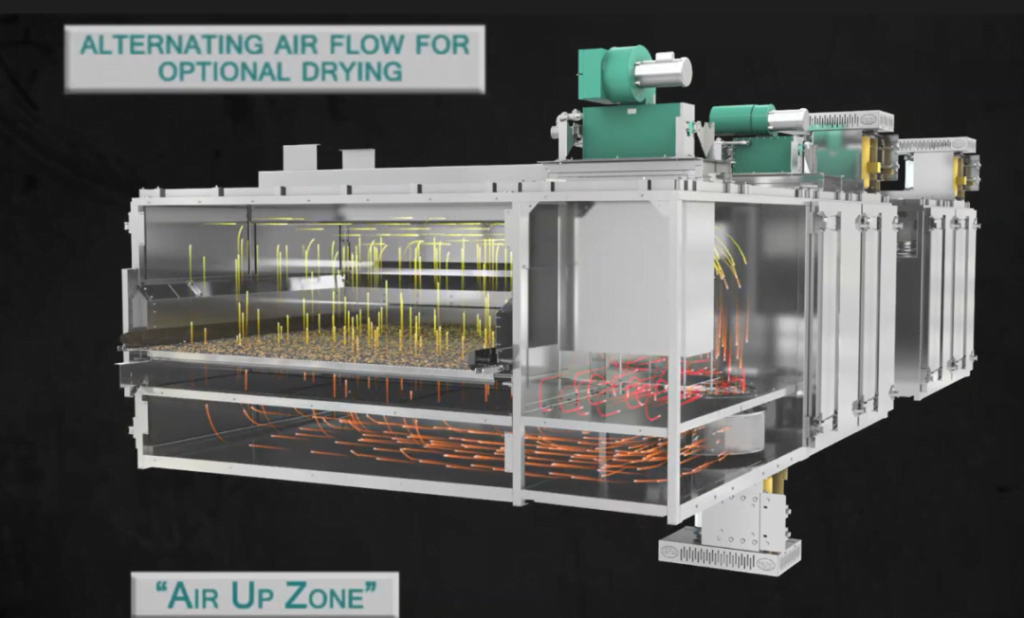

Flexibility: With upward or downward airflow (or both), the choice of product cooling, conveyor design and heating system is determined by the product and production process.

Versatility: The choice of media for heating systems includes steam, natural or non-natural gases, liquefied gas, electricity, thermal oil and geothermal water.

Control: Temperature control systems range from simple on/off indicating controls to the most sophisticated instrumentation driven through PLC menus to control drying and other equipment.

Effectiveness: Self-supporting method, segmented construction, and provision of self-driven conveyors with screen holes to reduce screening volume and improve cleaning intervals.

Minimum Losses: One-piece baffle construction facilitates containment of material, minimising losses while maintaining proper airflow through the product.

Easy Maintainability: The return conveyor is located outside the oven for easy cleaning. If required, the integral cooler is needed for the quickest stopping of drying and roasting operations and the temperature of the excluded material should be close to ambient temperature.

Quick Installation: Components are pre-assembled in the CPM WP plant, ensuring ease of installation on site and reducing the time required for installation.

Low Cost: Minimum pre-assembled parts with shipping tolerances can be provided to reduce costs. Reduces the cost of varying pass-through shipping requirements.

FAQ

Q: What is the CPM Wolverine Proctor Pet Food Dryer?

A: It’s a specialized dryer designed for efficient and quality drying of pet food, utilizing advanced technology for consistent results.

Q: How does this dryer benefit pet food production?

A: It offers precise temperature control, uniform drying, and versatility in handling different types of pet food, enhancing production efficiency.

Q: What innovative technologies are used in this dryer?

A: The dryer incorporates JetTube air handling and multi-zone temperature control for maximum efficiency and gentle drying.

Q: Can the dryer be integrated with packaging lines?

A: Yes, it can be integrated with packaging production lines for streamlined processing and distribution.

Q: What support does Lintyco provide for this machinery?

A: Lintyco offers extensive global after-sales support, ensuring access to services and maintenance.

Conclusion

In the specific case of pet food dryers, CPM Wolverine Proctor offers customized, high-quality solutions that cater to the diverse needs of pet food production. Their equipment’s flexibility, control, and efficiency address the unique challenges of pet food drying, ensuring consistent quality and minimal product loss. The integration with Lintyco packaging lines further enhances the value chain, streamlining the process from production to distribution.