Definitive Innovation, an Italian company, is an expert in the design and construction of raw material storage, extraction, transportation and batching systems. Explore personalized turnkey solutions and trust Definitive Innovation to find the perfect answer to your moving needs.

Definitive Innovation was founded by a team of professionals with over thirty years of international experience in demand processing. Today, Definitive Innovation provides customized solutions for various industries such as food, livestock, pet food, chemicals, pharmaceuticals, construction and plastics, ensuring excellent efficiency and quality.

Definitive Innovation prides itself on delivering high quality, bespoke turnkey solutions to its customers, backed by comprehensive support including advice, technical assistance and a fully stocked spare parts warehouse.

Technology from Definitive Innovations:Measurement,storage,extraction

,transportation,mix,filter,Industrial automation.

Innovative applications in the food industry

Managing the storage, handling and accurate dosing of all raw materials and additives in food processing is critical to ensuring efficiency and safety.

Definitive Innovation offers a wide range of solutions designed for industrial systems in the food industry. Thanks to its experience, we create cutting-edge solutions that guarantee absolute efficiency and safety in food production processes.

When Definitive Innovation designs systems for the food industry, it focuses on every step of the production process, from storage of raw materials to handling, from ingredients to the addition of vitamins, enzymes and colorants.

Definitive Innovation pays special attention to the geometric design of each machine and its components to ensure thorough removal of residue and easy cleaning.

Innovative applications in livestock and pet food industries

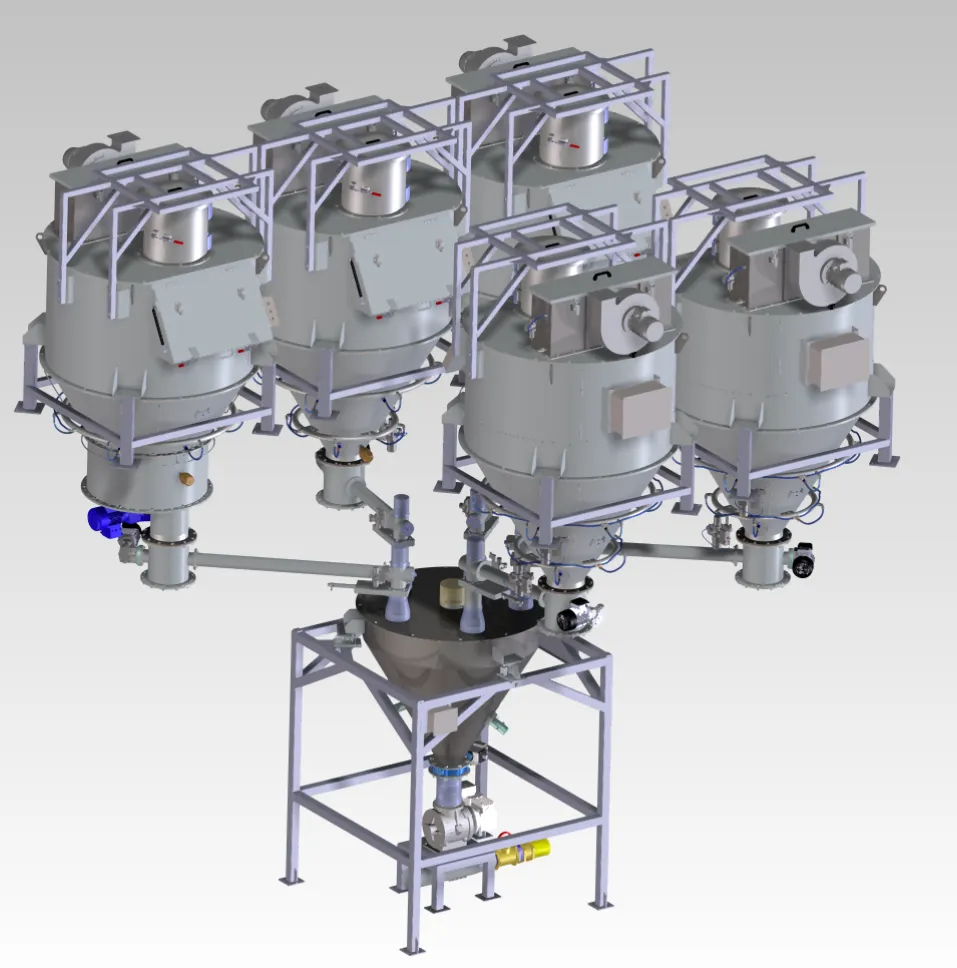

Accurate dosing is critical in livestock farming, especially for essential ingredients such as the amino acid methionine. Amino acids are the building blocks of protein and are essential for animal health and growth. Since animals cannot synthesize certain amino acids, such as methionine, on their own, it is necessary to incorporate them into the formula through pet food.

Definitive Innovation’s multi-dosing systems provide the necessary precision and reliability to guarantee the correct formulation of animal feed, comply with legal regulations and guarantee product traceability.

In the livestock and pet food industries, efficient production processes are crucial to ensure the quality and safety of the final product.

Our industrial systems are designed to optimize every stage of the process, from handling powdered and liquid raw materials to adding essential ingredients such as vitamins and minerals. Our solutions are used to produce a variety of products including supplements, vitamins and animal feed.

With our cutting-edge technology and attention to detail, we provide tailor-made solutions to meet the specific needs of all our customers.

Innovative applications in the chemical industry

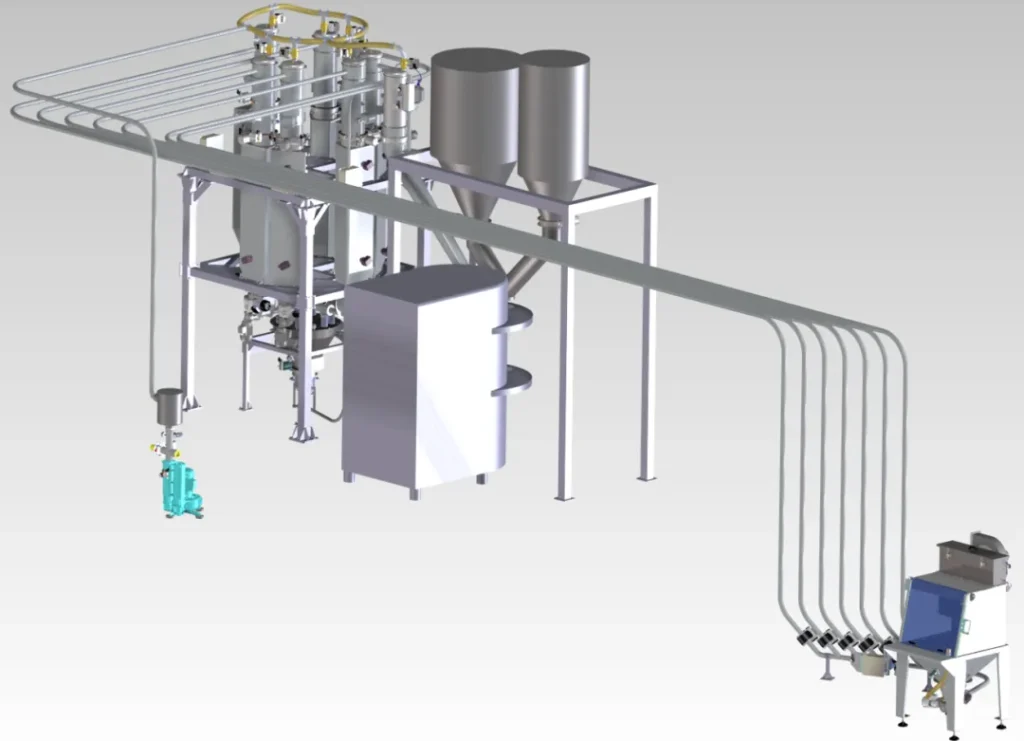

Definitive Innovation provides turnkey solutions and systems for the storage and handling of raw materials and powder additives in chemical plants.

Definitive Innovation’s systems are designed to power mixers, reactors and processing lines, transferring mixtures and primary products to chemical packaging and storage lines.

The Definitive Innovation system records alarms and production data by shift, batch and order, ensuring product traceability.

Automated management reduces the risk of human error and increases process efficiency and security.

Innovative applications in the cosmetics and pharmaceutical industries

Definitive Innovation is a leader in providing complete solutions for the cosmetic and pharmaceutical industries. From individual machines to finished systems, guaranteeing the highest quality and reliability, operating nationally and internationally.

Through the automation of processes, efficiency and precision are guaranteed, providing cutting-edge solutions for every production need.

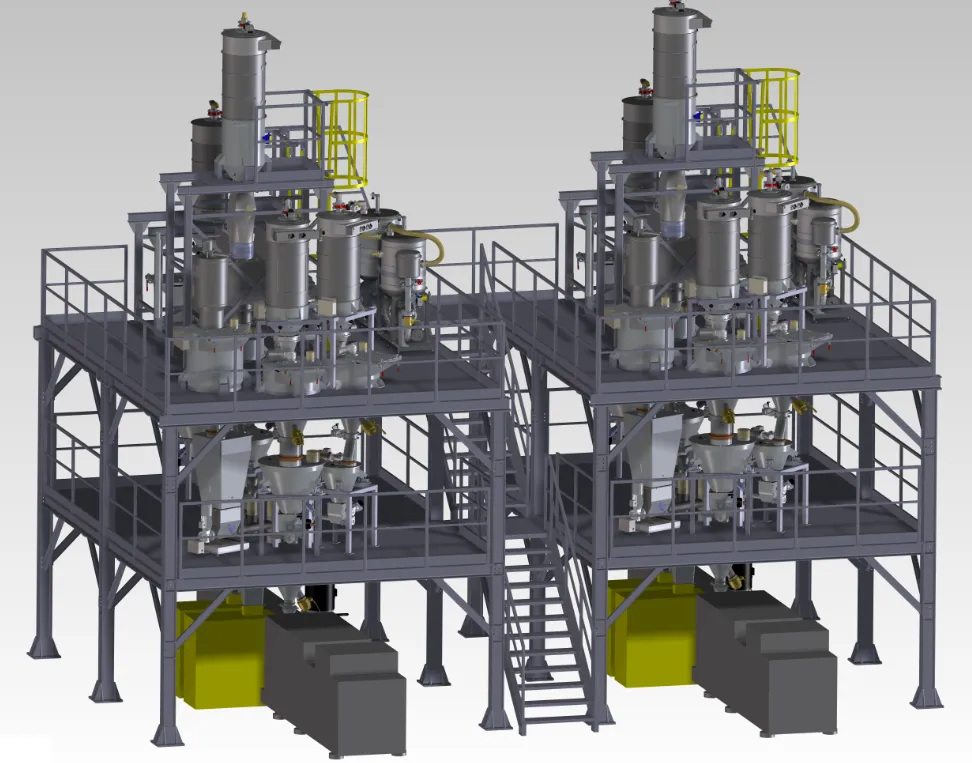

Definitive Innovation’s systems and machines for the cosmetics industry guarantee speed and reproducibility in dosing. Its systems are designed to minimize operator exposure to dust and reduce material dispersion, reducing human error, ensuring the highest production quality and ensuring a safe and healthy working environment.

Definitive Innovation’s software can autonomously and efficiently manage recipes containing one to multiple ingredients, even when left unattended.

Products are automatically loaded via vacuum conveyors, and raw materials are identified via barcodes. All operations are managed from a PC, allowing the operator to select recipes, check the weight of each ingredient during the batching process and control the automatic save cycle.

In the pharmaceutical industry, precise management of bulk ingredients, often in minute amounts and expensive, is critical. Our machines and systems reduce waste and ensure precise measurements and meticulous data recording.

With in-depth knowledge of the pharmaceutical industry, Definitive Innovation takes all application specifications and ingredient properties into account during the design phase. These often have unique features that require special design choices, such as using small hoppers with mirrored finishes. Our raw material management solutions guarantee ingredient integrity and safety. Avoid contamination to ensure final product quality and consumer safety.

Due to the focus on contact materials, Definitive Innovation selected precious materials such as 304 and 316L stainless steel and polymers such as PTFE that are particularly resistant to oxidation or chemical reactions.

In addition, our batching and weighing systems follow strict hygiene practices and are regularly cleaned and sanitation services are provided.

Innovative applications in the plastics industry

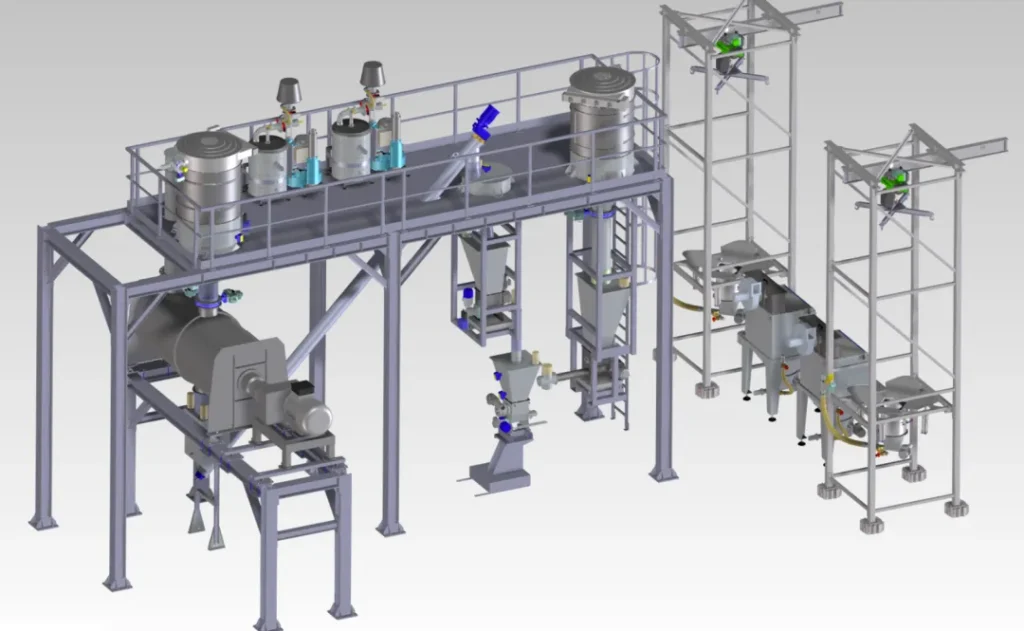

Definitive Innovation designs and manufactures turnkey systems for the storage, transportation and batching of raw materials used in the production of plastic pellets. Focus on the processing of recycled high-tech polymers and high-quality plastic polymers.

Definitive Innovation’s systems for the plastics industry are designed to produce high-quality high-tech polymers, precisely and accurately following the entire compounding process. With its systems, the necessary additives are added and metered to obtain high-quality products.

The raw materials are converted, mixed with powders and granules, colored and pigmented according to the specific needs of the final product. This makes it possible to obtain specific mechanical properties, such as weather resistance for outdoor furniture or elasticity for food films.

Over the years, Definitive Innovation has expanded the application of its systems to a wide range of industrial sectors, including masterbatches, compounds, adhesives, rubbers, glues, biomaterials, stretch films and special processes.

With Definitive Innovation’s systems, customized products can be created for a variety of applications in the following sectors: Automotive, Medical, Indoor and outdoor furniture, Construction, Packaging,Bioplymers.

Definitive Innovation stands out for its excellent technological solutions and the use of advanced production control and management systems. In fact, Definitive Innovation offers very advanced software for data collection, management of industrial automation systems, process control and supervision, automated warehouses up to remote assistance.

Production speed, reduction of material waste and adaptation of processes to specific needs make its systems for the plastics industry essential to remain competitive and meet evolving market demands.

Leading Turnkey Packaging Solution–Lintyco

No matter what product you are making, it needs to be packaged. Automated packaging is especially important for the last process. With the LINTYCO automated packaging machine, the overall coordination will be greatly improved. In the past, we have cooperated with many Fortune 500 companies and helped thousands of factories increase their overall production capacity by two to three times.

Lintyco is a leading provider of equipment and services solutions for packaging beverage, food, home and personal care products in pouch, can, glass and other materials. With over 40,000 machines installed in more than 190 countries, we have nearly 20 years of proven experience, with a strong focus on the factory of tomorrow with advanced systems, line engineering and innovation. Our 500+ employees worldwide are passionate about providing solutions that fulfil customer needs and boost the performance of their lines, products and businesses. Delivering this level of performance requires that we stay flexible. We continuously ensure we understand our customers’ changing challenges and commit to meeting their unique performance and sustainability goals. We do this through dialogue and by understanding the needs of their markets, production and value chains. In turn, we apply our solid technical knowledge and smart data analytics to ensure lifetime productivity reaches its full potential. We call it Performance through Understanding.

Contact our 1 vs 1 experts now to get a comprehensive understanding of your project !