Introduction

If you’ve ever purchased food in a stand-up pouch, you’ve encountered a product created by a Doypack machine. A Doypack machine is a type of packaging equipment designed to form, fill, and seal flexible pouches, most commonly used for food, beverages, and other consumer goods. These pouches are unique because they can stand upright on shelves, offering both convenience and aesthetic appeal. The machine derives its name from the “Doypack,” a pouch design invented by Frenchman Louis Doyen in 1962.

Why are businesses turning to doypack machines?

Doypack machines offer a host of benefits to manufacturers, retailers, and consumers alike.

Unmatched Efficiency Doypack machines streamline the packaging process, significantly reducing production time and labor costs. With the ability to produce hundreds of pouches per minute, these machines can dramatically increase your output without sacrificing quality. This efficiency boost translates directly to improved profitability and competitiveness in the market.

Versatility in Packaging One of the most significant advantages of doypack machines is their ability to handle a wide range of products. From liquids and powders to granules and solid items, these machines can package virtually anything. This versatility makes them ideal for industries as diverse as food and beverage, cosmetics, pharmaceuticals, and household products.

Eco-Friendly Packaging Solutions In an era where sustainability is paramount, doypack machines offer an environmentally conscious packaging option. The pouches produced require less material than traditional rigid containers, resulting in a reduced carbon footprint. Additionally, many doypack materials are recyclable or biodegradable, aligning with consumer demands for more sustainable packaging options.

Cost-Effective Production While the initial investment in a doypack machine may seem substantial, the long-term cost savings are significant. These machines reduce material waste, minimize labor requirements, and increase production speed – all factors that contribute to a lower cost per unit. Over time, this translates to substantial savings and improved profit margins for businesses.

Enhanced Product Protection Doypacks created by these machines offer superior protection for your products. The flexible yet durable materials used in their construction provide excellent barriers against moisture, air, and light, ensuring that your products remain fresh and intact throughout their shelf life. This enhanced protection can lead to reduced product waste and increased customer satisfaction.

Space-Saving Storage and Transportation The compact nature of doypacks offers significant advantages in terms of storage and transportation. These pouches can be efficiently stacked and stored, taking up less warehouse space compared to rigid containers. During transportation, their lightweight and flexible design allows for more units to be shipped in a single load, reducing logistics costs and environmental impact.

Marketing and Branding Opportunities Doypack machines produce packaging that serves as a powerful marketing tool. The large, printable surface area of doypacks provides ample space for eye-catching graphics, branding elements, and product information. The stand-up nature of these pouches ensures prominent shelf presence, making your products more likely to catch consumers’ attention in crowded retail environments.

How Does a Doypack Machine Work?

A Doypack machine operates using a combination of forming, filling, and sealing mechanisms.

- Pouch Loading: Empty, pre-made pouches are loaded into the machine using a pouch feeding system, which can be a conveyor or carousel.

- Pouch Opening: The machine utilizes mechanisms like vacuum suction cups or mechanical grippers to open the pouches without damaging them.

- Filling: Once opened, the machine fills the pouches with the desired product. Different filling systems may be employed based on the product type, such as volumetric or weight-based systems.

- Sealing: After filling, the pouches are sealed securely using methods like heat sealing or ultrasonic sealing to ensure freshness and prevent leakage.

- Output System: Finally, filled and sealed pouches are discharged from the machine onto a conveyor belt or into secondary packaging

Each stage of the process is tightly controlled to ensure precision and consistency, producing pouches that are durable, attractive, and leak-proof.

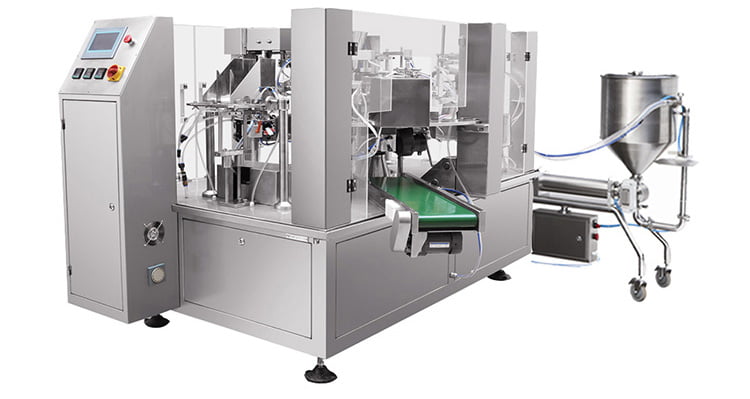

Main Components of a Doypack Machine

While the exact setup may vary, most Doypack machines consist of three key components: the filling system, sealing mechanism, and pouch formation unit.

Filling System

This part of the machine ensures the correct amount of product is dispensed into each pouch. Depending on the product, the filling system can be adapted for liquids, powders, granules, or solids. The accuracy of this system is crucial to avoid underfilling or overfilling, which can result in product loss or wastage.

Sealing Mechanism

Once filled, the pouch needs to be sealed to protect its contents. The sealing mechanism ensures airtight seals, using heat or pressure to close the pouches. This part of the process is essential for maintaining the integrity and shelf life of the product.

Pouch Formation

Before anything else happens, the machine forms the pouches from flat material. The pouch formation component folds, shapes, and creates the stand-up feature that makes Doypacks so popular. The design can be customized to suit the needs of different products, offering options like resealable zippers or spouts.

Types of Doypack Machines

Doypack machines come in various models to meet different production needs. Depending on the volume and type of product being packaged, businesses can choose between automatic, semi-automatic, and customizable machines.

Automatic Doypack Machines

These machines are fully automated and designed for high-speed production environments. They require minimal human intervention, making them ideal for large-scale operations where speed and efficiency are top priorities.

Semi-Automatic Doypack Machines

For smaller operations or those that don’t require high production rates, semi-automatic Doypack machines offer more flexibility. They still perform the same basic functions, but with a bit more manual control, which can be beneficial for specialized or short-run products.

Custom Doypack Machines

Many Doypack machine manufacturers come with options for customization, allowing to adapt the machine to customer specific product requirements. Whether you need resealable zippers, spouts, or unique shapes, there’s a machine out there that can be tailored to meet your exact needs.

Industries That Benefit from Doypack Machines

Doypack machines aren’t limited to a single industry. In fact, they’re used across multiple sectors due to their versatility and the growing demand for flexible, convenient packaging solutions.

Food and Beverage Industry

Perhaps the most common use of Doypack machines is in the food and beverage sector. From snacks and sauces to juices and powders, these machines can handle a wide variety of consumable products. The flexible pouch format also helps prolong shelf life while being easy to transport and store.

Pharmaceutical Industry

The pharmaceutical industry also relies on Doypack machines for packaging things like supplements, tablets, and medicinal powders. The pouches are tamper-evident, ensuring the safety and integrity of sensitive pharmaceutical products.

Cosmetic and Personal Care Industry

Cosmetic products such as lotions, creams, and gels are often packaged in Doypack pouches for easy use and storage. The customizable pouch options make them a favorite for personal care brands aiming for a unique, consumer-friendly design.

Pet Food and Animal Products

The convenience and durability of Doypack pouches also make them popular in the pet food industry. Pet owners appreciate the resealable designs, which keep food fresh and minimize waste.

Household Products

Detergents, cleaning solutions, pet food – you name it, doypack machines can package it. They’re making household chores a little bit easier, one pouch at a time. Who knew doing laundry could be so… well, not exciting, but at least more convenient?

How to Choose the Right Doypack Machine

Selecting the perfect Doypack machine for your business involves considering several factors.

Production Speed and Capacity

Think about how many pouches you need to produce daily. High-capacity machines might be more expensive but can handle large-scale operations, while smaller machines are ideal for businesses with lower production needs.

Packaging Material Compatibility

Ensure that the machine you choose can handle the type of material you want to use, whether it’s plastic, paper, or aluminum. Some machines may also support multilayer materials for enhanced protection and durability.

Budget Considerations

While you want to invest in a quality machine, it’s important to choose one that fits within your budget. Look for a machine that meets your production requirements without going overboard on unnecessary features.

Top Doypack Machine Manufacturers in the Market

While I can’t play favorites here, there are some big names in the doypack machine world. Companies like Volpak, Mespack, and Lintyco Pack are like the rock stars of the packaging industry. Do your research, read reviews, and maybe even try to get a demo before you commit.

Common Challenges with Doypack Machines

Like any industrial equipment, Doypack machines come with their own set of challenges.

Maintenance and Downtime

Regular maintenance is crucial to keep the machine running smoothly. If not properly maintained, breakdowns can lead to costly downtime, affecting your production schedules.

Incorrect Pouch Formation

Sometimes, issues with pouch formation can occur, resulting in uneven or improperly sealed pouches. This is often due to improper machine settings or wear and tear on components, so regular inspections are necessary to prevent this.

Future Trends in Doypack Machines

As technology continues to evolve, so do the capabilities of Doypack machines.

Automation and AI Integration

More advanced machines are starting to incorporate AI and automation features, allowing for smarter production lines with less human intervention. These advancements can help improve efficiency, reduce errors, and lower labor costs.

Sustainable Packaging Innovations

As consumers demand more eco-friendly packaging, expect to see innovations in sustainable materials and production processes. The future of Doypack machines may include even more options for biodegradable or recyclable pouch materials, helping businesses stay ahead of environmental regulations and consumer expectations.

Conclusion

And there you have it, folks – the wonderful world of doypack machines laid bare. From their humble beginnings to their bright future, these machines are truly revolutionizing the way we package products. They’re efficient, cost-effective, versatile, and frankly, pretty darn cool. Whether you’re a business owner looking to up your packaging game, or just a curious consumer wondering how your favorite snacks get into those convenient pouches, I hope this deep dive into doypack machines has been as enlightening for you as it has been for me. Remember, the next time you tear open a stand-up pouch, give a little nod to the hardworking doypack machine that made it possible. Here’s to the unsung heroes of the packaging world – may they continue to fold, fill, and seal their way into our hearts (and pantries)!

FAQs

- What products can be packaged using a Doypack machine? Doypack machines can package a wide range of products, including liquids, powders, granules, and solids, making them versatile for many industries.

- Are Doypack pouches eco-friendly? Yes, many Doypack pouches are made from recyclable or biodegradable materials, aligning with sustainable packaging trends.

- How fast can a Doypack machine produce pouches? The production speed varies depending on the machine model, but high-speed machines can produce thousands of pouches per hour.

- Can Doypack machines be customized? Absolutely. Many machines offer customizable options such as resealable zippers, spouts, and different pouch sizes to meet specific needs.

- What is the lifespan of a Doypack machine? With proper maintenance, a Doypack machine can last several years, making it a worthwhile investment for businesses.