Introduction

As with any kind of food production, improving efficiency and enhancing traceability are key concerns for many in the industry. UK-based GA Pet Food Partners is one of Europe’s leading pet food manufacturers, exporting premium pet food to more than 40 countries around the world.

World-class Automation Project For Pet Food Factory

GA Pet Food looked for ways to improve efficiency and traceability through automated material handling solutions and selected Daifuku as a partner to help achieve this.

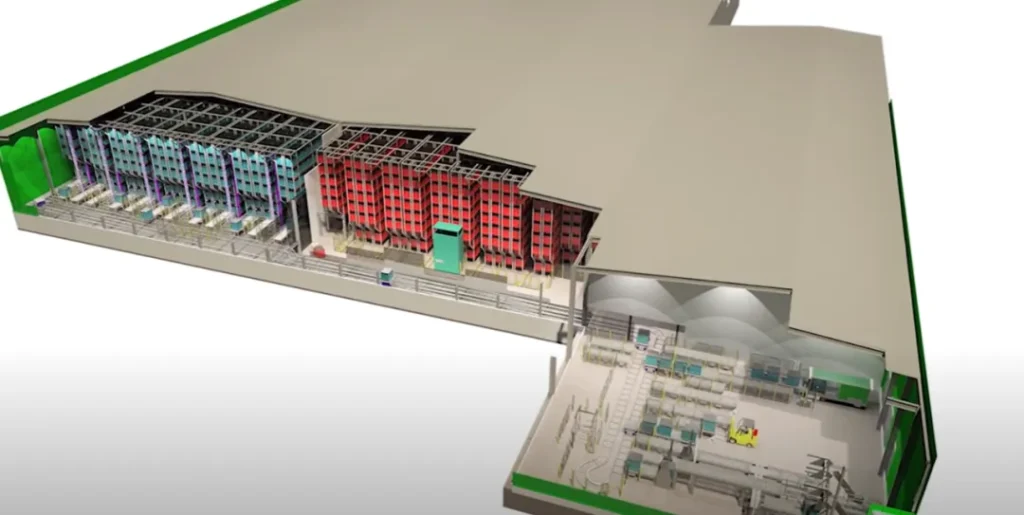

Factory automation specialist Daifuku worked as part of a collaborative team to create a world-class factory for GA Pet Food Partners pet food.

Daifuku played a major role in creating Europe’s most advanced production facility dedicated to producing high-quality ‘own label’ pet food.

GA Pet Food Partners’ Chorley, Lancashire facility received an automated material handling system consisting of two automated storage and retrieval systems (one for raw materials and the other for finished products) and sorting transfer vehicles from Daifuku, as well as systems from other partner companies.

Storage Options For Dry Pet Food Ingredients

GA Pet Food Partners first approached Goplasticpallets in 2017, looking for a large container suitable for automated handling and storage of bulk dry pet food ingredients. After a considerable period of consultation with GA Pet Food Partners to discuss exactly how the container would be used, Goplasticpallets recommended its largest plastic pallet box – the GoPalletBox 1311S 3R, measuring 1300mm x 1150mm x 1250mm and offering a storage capacity of up to 1400 litres.

For GA Pet Food Partners, automation isn’t just about labor savings or cost cutting. Instead, technology has enabled the business to increase output by 30%, improve overall plant efficiency (15% increase in extruder uptime) and maintain world-class quality standards. The use of cutting-edge automation has also enabled the company to remain flexible – one of its key areas of competitive advantage in the global pet food production space. This has all been accomplished without increasing plant headcount.

After opening its fully automated production facility, the next item on GA’s agenda is its finished product packaging line, which will further enhance its service levels to customers around the world.