As a machinist with 20 years of experience in a packaging machine plant, I’ve learned that proper cleaning and maintenance are crucial to keep your horizontal form fill seal (HFFS) machine running smoothly. In this blog post, I’ll share my expert tips on how to properly clean and maintain your HFFS machine to ensure optimal performance, reduce downtime, and extend its lifespan.

Why is cleaning your HFFS machine important?

Regular cleaning of your HFFS machine helps to:

- Prevent product contamination and ensure consistent product quality.

- Minimize wear and tear on machine components, reducing repair costs and extending the machine’s lifespan.

- Maintain compliance with health and safety regulations.

- Enhance overall machine efficiency and reduce downtime.

Required tools and cleaning agents

Before we dive into the cleaning process, make sure you have the following tools and cleaning agents on hand:

- Soft brushes or non-abrasive cleaning pads

- Vacuum cleaner or compressed air

- Food-grade lubricants (for lubricating moving parts)

- Food-safe cleaning solutions or mild soap and water

- Clean, lint-free cloths or paper towels

Step-by-step cleaning guide for your HFFS machine

Follow these steps to clean your HFFS machine properly:

Step 1: Power off the machine and disconnect it from the power source

Before you begin cleaning, ensure the machine is powered off and disconnected from the power source to prevent electrical hazards.

Step 2: Remove product debris

Using a soft brush or non-abrasive cleaning pad, gently remove any product debris from the machine’s surfaces, including the film rollers, forming tubes, and sealing jaws. A vacuum cleaner or compressed air can also be used to remove loose debris from hard-to-reach areas.

Step 3: Clean the product contact surfaces

Using a food-safe cleaning solution or a mild soap and water mixture, dampen a lint-free cloth or paper towel and wipe down all product contact surfaces, such as the film rollers, forming tubes, and filling nozzles. Be sure to rinse these surfaces thoroughly with clean water and wipe dry.

Step 4: Clean the sealing areas

Dampen a clean, lint-free cloth or paper towel with a food-safe cleaning solution or mild soap and water mixture, and gently clean the sealing jaws, cutting knives, and any other sealing components. Rinse with clean water and wipe dry.

Step 5: Inspect and clean the machine exterior

Inspect the exterior of the machine for any buildup of dust or debris. Using a clean, damp cloth or paper towel, wipe down the machine’s exterior surfaces to remove any dirt or grime.

Step 6: Lubricate moving parts

Apply food-grade lubricants to any moving parts that require lubrication, such as bearings, chains, and gears. This helps to minimize wear and tear and ensure smooth operation.

Step 7: Reconnect the power source and perform a test run

After cleaning, reconnect the machine to the power source and perform a test run to ensure all components are functioning correctly.

Final thoughts

Regular cleaning and maintenance of your HFFS machine are essential for optimal performance and a long-lasting machine life. By following the steps outlined in this guide, you can keep your machine in top condition and ensure consistent, high-quality packaging for your products. Remember, a clean machine is a happy machine!

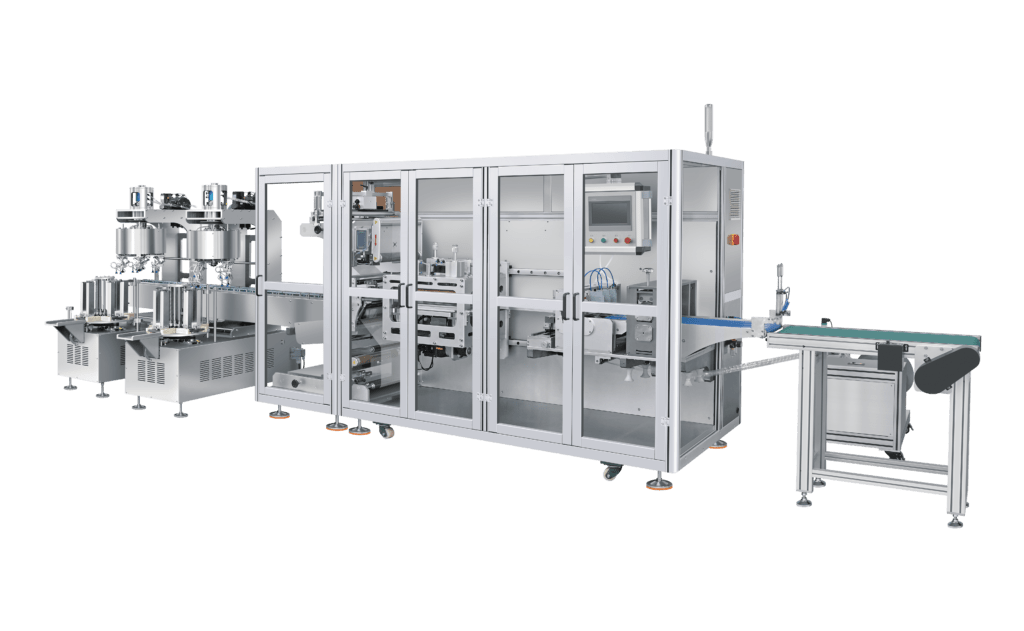

Lintyco is a pioneer and leader in automated Horizontal Form Fill Seal Machines and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.