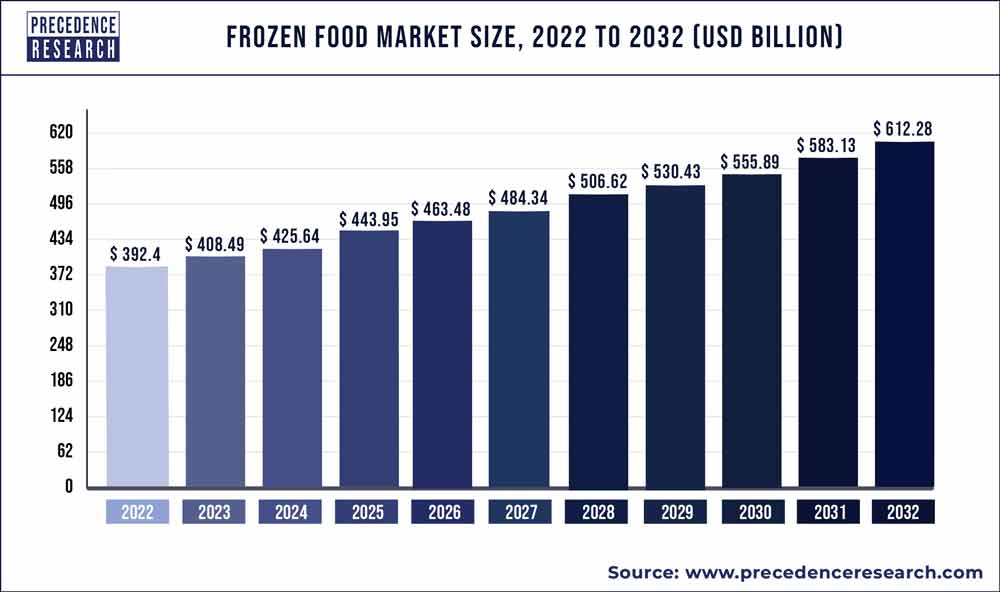

The estimated global frozen food market size was USD 392.4 billion in 2022 and it is projected to surpass around USD 612.28 billion by 2032 with a registered CAGR of around 4.6% from 2023 to 2032.

Restraining Factors

Cold chain logistics is a crucial requirement for the storage of frozen food in all nations. Emerging nations still lack the infrastructure for cold chains and are unable to provide safe products to their citizens. Although these foods have a long shelf life, the lack of infrastructure results in wastage and a loss to the producers. Investments are low in developing nations due to the financial crisis, which is hindering the growth of cold chain businesses in this area. However, emerging nations have many lucrative funding opportunities due to the changing consumer preferences towards frozen foods and their increasing acceptance.

Nielsen Market Research Company reported that frozen and shelf-stable foods were prominent in shopping carts during the COVID-19 pandemic. Consumers stockpiled these food items, which helped to reduce the number of trips they needed to make to the grocery store. Nielsen data shows that frozen foods were in the top five food categories with significant sales growth from March to June 2020.

While some consumer purchasing habits, such as purchasing frozen products, may extend beyond the pandemic, other factors may also influence frozen food sales in the future. The impact of the pandemic on purchasing power, is not equal among consumer groups. Consumer groups that are financially impacted may adopt new shopping strategies. For instance, some may opt for more frozen foods over fresh foods to reduce costs. Besides pandemic impacts, frozen food is one of the most convenient ways for consumers to find meal solutions. In recent years, food manufacturers have focused on the frozen food category by developing more delicious and nutritious products. Given these facts, it is worth exploring frozen food sales trends in Alberta. Such analysis could help Alberta food processors in exploring potential opportunities in frozen food manufacturing.

Key market players in the frozen Foods Market

- General Mills Inc (US)

- Conagra Brands, Inc. (US)

- Grupo Bimbo S.A.B. de C.V. (Mexico)

- Nestle SA (Switzerland)

- Associated British Foods plc (UK)

- Ajinomoto (Japan)

- Vandemoortele NV (Belgium)

- LantmannenUnibake International (Denmark)

- Cargill (US).

- Unilever (Netherlands)

- Kellogg Company (US)

- McCain Foods Limited (Canada)

- Kraft Heinz Company (US)

How to start a quick IQF business.

- Product research – Thoroughly research what types of frozen foods are in demand and what gaps exist in the market. Test recipes to find your niche.

- Food safety compliance – Ensure your facility, processes and products meet all food safety regulations. This is critical for building customer trust.

- Facility and equipment – You’ll need commercial freezer space and machinery suited for scaling production. Consider co-packing options initially.

- Recipes and packaging – Develop your recipes and source packaging materials approved for frozen storage and microwave/oven reheating.

- Distribution strategy – Decide how you’ll get products to customers – direct store delivery, broad-line distributors, online sales etc.

- Branding and marketing – Create a brand identity and promotional plan to engage customers and gain market visibility.

- Financial planning – Create realistic sales forecasts and budgets. Consider sources of startup capital like loans, grants or crowdfunding.

- Team building – Assemble key talent in areas like product development, operations, sales and financial management.

- Food safety program – Implement proper controls and recordkeeping for food safety, temperature control and supplier management.

Starting small and prioritizing food safety compliance will establish a solid foundation for your frozen food business.

Packing Equipment for Frozen Food

Lintyco is a pioneer and leader in automated Pouch Packaging Machines and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.

FAQ

1. What Should I Consider in Terms of Food Safety and Compliance?

Answer: Ensuring your frozen food business complies with food safety standards is critical. This includes having proper storage, handling procedures, and using packaging materials that are suitable for frozen foods.

2.What Are the Initial Steps to Start a Frozen Food Business?

Answer: Starting a frozen food business involves identifying market demand, ensuring food safety compliance, selecting the right packaging and freezing technology, and developing a solid business plan that includes financial planning, branding, and distribution strategies.

3.What Should I Consider in Terms of Food Safety and Compliance?

Answer: Ensuring your frozen food business complies with food safety standards is critical. This includes having proper storage, handling procedures, and using packaging materials that are suitable for frozen foods.

4.How Can Lintyco Packaging Help in My Frozen Food Business?

Answer: Lintyco Packaging offers a range of automated packaging machines and end-to-end packaging systems that are ideal for frozen food businesses. Our expertise and technology can help streamline your operations and enhance product quality.