- Home

- Industries

- Granule

- Biscuits

Cookie Packaging Machine

Machine Choice

Rotating Biscuit Premade Pouch Packaging Machine

Our Premade Pouch Packaging Machine covers SS304 and adopts German/Japanese electronic components.Package up to 80 Bags/Min. We provide layout drawing service ,OEM service and decent delivery time.

Biscuit Vertical Form Fill&Seal Packing Machine

Vertical Form Fill & Seal Machine, as a classic solution for Granule packaging, is also one of the choices. Easy to operate,Package Up to 60 Bags/Min,Low price .If you have no special requirements for the appearance of the product packaging, then it is a good Choice.

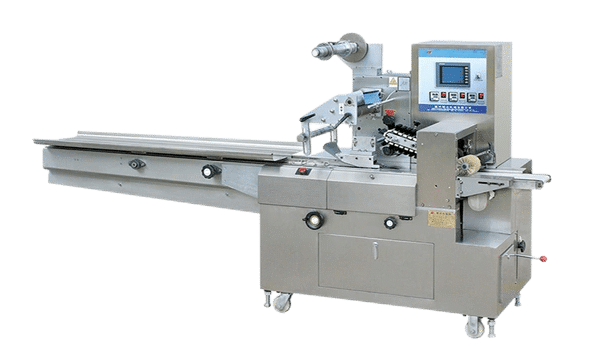

Biscuit Flow Wrapping Machine

Horizontal Flow wrapper, also as a classic solution for cookie packaging, is also one of the choices. Package Up to 290 Bags/Min, the servo Intelligent control,advanced PLC touch screen, run with low noise .If you have high special requirements for the accuracy of the product packaging, then it is a good Choice.

Ultimate FAQ Guide

The fully automatic packaging machine can wrap cookies, pastries, and other rigid food or non-food items.

Feel free to contact the sales team to provide free packaging design drawings!

The cookie packaging machine’s accuracy can be precise, down to the weight and size of each cookie.

To maintain the cookie packaging machine, it’s important to pay attention to daily cleaning, lubrication, and replacing worn parts promptly.

Download your maintence list Here

The lifespan of the food packaging machine is dependent on many factors, such as the quality and maintenance of the machine, which usually lasts between 5-10 years.Lintyco offer 1 years warrant time.

Lintyco can hook you up with a free packing line solution for your factory that’s perfect for you.

Here are a few things we can expect in the future of the cookie wholesale market.

-As people become more health -conscious, they’ll want healthier cookie options with less sugar, artificial ingredients, and more whole grains. This is a great opportunity for innovative healthy cookie brands.

– There will be a variety of cookie options, including ones that taste good for certain diets, seasons, and regions.

– Customers will be able to customize cookie flavors, mix-ins, shapes etc. Customers will be drawn to this personalized experience.

– By increasing automation in mass production and packaging, we can reduce costs and allow for smaller batch customization.

– E-commerce sales of cookies will keep growing rapidly due to the increasing global internet penetration.

-Brands like Oreo and Cadbury are expanding globally through strategic acquisitions, partnerships and building local manufacturing.

– It’s expected that some big players will acquire small/regional brands to build market share in new categories/segments and benefit from economies of scale.

– Sustainability focus – Packaging solutions will move towards eco-friendly materials with transparency around sourcing/carbon footprint attracting conscious customers.

The future looks bright for innovators who cater to evolving tastes with variety, customization, healthiness, and sustainability while leveraging automation and e-commerce globally. People want pretty, high-quality cookie packaging, so companies need to come up with advanced packaging solutions. As the industry comes up with new product variations, packaging requirements are getting more and more specific.

With all this in mind, the cookie packaging industry outlook seems really promising. The future of leadership will be defined by intelligent, digitally integrated systems that can adapt to customized packaging needs. Early adopters get an edge over the competition.

Meanwhile, technology is constantly changing and diversifying opportunities. The advanced applications in robotics, Industry 4.0 connectivity, and predictive maintenance are expanding the scope and value of packaging lines. Globalization requires high-quality premiums across the vast international distribution.

If you need help with your cookie product, Feel free to contact us!