Candy packaging Machine

An automatic weighing and filling machine fills and seals bags or pouches with hard candy or infused gummies. A conveyor line moves the candy pieces and counts them into the correct number per bag.

With the advanced PLC control system, the filling head places an empty wrapper or pouch underneath and drops the required candy pieces into it. You fold over and seal the top of the wrapper to contain the candy pieces inside. Some candy packaging machines also twist the wrapper to completely seal the contents.

These candy wrappers use heat, glue, or a clip to securely fasten the wrapper. Some machines can print information, nutrition facts, or logos on wrappers, and insert promotions like coupons. For the candy industry, candy packaging machines can work quickly, filling thousands of small bags or pouches in an hour. Machines reduce the handling of the candy and ensure accurate, consistent bag or pouch weights.

Proper packing also keeps candy fresh by sealing in liquids or preventing air exposure until consumed. Candy packers improve production efficiency and are cost-effective for large manufacturers. The goal is to produce shelf-ready, sealed products straight from the packaging equipment.

Sample bag

Machine Choice

Rotating Premade Pouch Candy Wrapper Machine

Our Premade Pouch Packaging Machine covers SS304 and adopts German/Japanese electronic components.Package up to 80 Bags/Min. We provide layout drawing service ,OEM service and decent delivery time.

Vertical Candy Form Fill&Seal Machine

Vertical Form Fill & Seal Machine, as a classic solution for Granule packaging, is also one of the choices. Package Up to 60 Bags/Min,Low price .If you have no special requirements for the appearance of the product packaging.Then it is a good Choice.

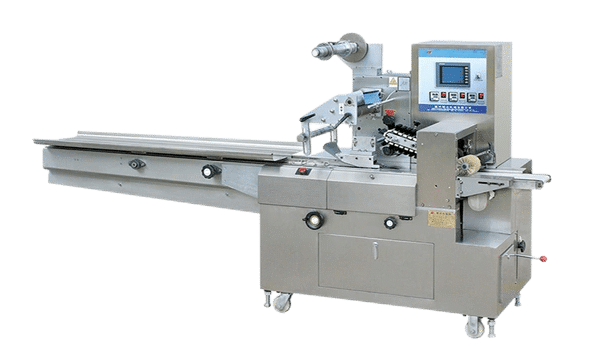

Horizontal Flow Pack Wrapper For Candy

Candy flow Pack wrapper, as a classic solution for Granule packaging, is also one of the options.Package up to 290 bags per minute with the servo intelligent control system. It runs quietly and is a great option if you need precise candy packaging.

Ultimate FAQ Guide

The fully automatic candy packaging machine can package various types of candy and chocolate products. You can use it for candies of different sizes and shapes.

The optional parts for the candy packaging machine include a motor, a control system, whether to use the German Siemens brand, a drive conveyor belt, a weighing machine, a metal detector, and many other components.

Candy packaging machines can package candy according to relevant standards. If you want more customization, you can request a higher level of support.

The lifespan of the food wrapping machine is dependent on many factors, such as the machine’s quality and maintenance, which usually last between 5-10 years.