Meat packaging Machine

Automatic meat packaging machine weighs, fills and seals meat into trays, pouches or vacuum packs. Meat is loaded into a hopper and weighed into proper part sizes before packaging. For meat vacuum packaging machine , air is removed from the pack before sealing to prevent exposure. Some sealers add inert gases like nitrogen or carbon dioxide to displace oxygen and preserve freshness.

Food and meat packing machines can process thousands of packs per hour, enabling high-volume production. They ensure consistent pack weights and reduce handling for efficiency and food safety. Proper packing, sealing, chilling and sanitation prolong shelf life. Pre-weighed meat is convenient for consumers and food service.

Machines may print date stamps, temperature requirements or nutrition labels on the packaging during the automated packing process. Automated packers integrate many functions including weighing, tray filling, vacuumpacking, sealing and inline printing. They produce shelf-ready, pre-packed meat for retail and wholesale distribution.

Sample bag

Machine Choice

Rotating Premade Pouch Packaging Machine for Ground meat

Our Premade Pouch Packaging Machine covers Stainless Steel SS304 and adopts German/Japanese electronic components.Package up to 80 Bags/Min. We provide layout drawing service ,OEM service and decent delivery time.

Vertical Form Fill&Seal Meat Packaging Equipment

Vertical Form Fill & Seal Machine, as a classic solution for Granule packaging, is also one of the choices. Package Up to 60 Bags/Min,Low price .If you have no special requirements for the appearance of the product packaging, then it is a good Choice.

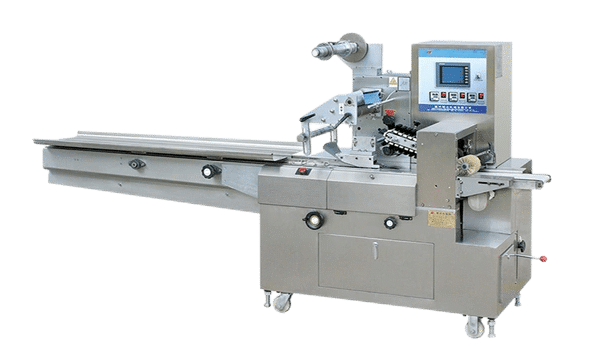

Sausage Wrapping Machine

Horizontal Form Fill & Seal Machine, also as a classic solution for Granule packaging, is also one of the choices. Package Up to 290 Bags/Min, the servo Intelligent control, run with low noise .If you have high special requirements for the accuracy of the product packaging, then it is a good Choice.

Ultimate FAQ Guide

Meat packing machines work with plastic trays, vacuum bags, pouches, cartons and other packaging.

Meat packing machine prices range from $20,000 to $500,000 depending on the model, capacity and level of automation.

A meat packing machine automatically portions, fills and seals meat packages. It has a meat feeding system, weighing and portioning unit, packaging units and a sealing system.

Key features: precise electronic scales, cut-off device for portions, interchangeable tools, hygienic design, programmable controls, quality monitoring, automated maintenance.

Yes, machines can handle most meat types with customizable tools and adjustments for size, shape, density and moisture levels.

Packaging options include trays, MAP trays, vacuum bags, shrink bags, skin packs etc. Precut or form-fill-seal options are available.

Most meat packing machines can handle both fresh and frozen meats with minor adjustments to feeding, portioning and sealing systems.

Output ranges from 5 to 100 packs per minute depending on pack size, meat type and machine complexity. Suitable for small to large scale operations.

Yes, machines offer customizable features for portion sizes, pack styles, labeling,monitoring and rejection systems specific to meat products and brands.

Accuracy typically within ±1-5% depending on scales, portioning tools and product consistency. Higher precision available for some machines.

Features include easy-to-clean surfaces, food-grade materials, automatic tool and conveyor sanitation, designated cleaning modes and CIP systems.

Additional functions like labeling, printing, metal detection and x-ray inspection are common. Automated film changing is available for form-fill-seal machines.

Quality control systems including checkweighers, x-ray and metal detectors can detect problems and divert defective packs for manual inspection.

Cleaning and maintenance is easy with smooth surfaces, easy-to-disassemble parts, designated cleaning modes and CIP systems. Meets hygiene standards.

Safety features include guards, light curtains, emergency stops, non-slip surfaces, lockout systems, metal detectors and lockable controls.

Integration into automated meat packaging lines is possible through connecting machines with other equipment like cameras, robotic arms and conveyors.

Power requirements vary – single or 3-phase, 380V – 480V, up to 50kW depending on machine configuration, size and complexity. Air and water hookups also needed.

Machines comply with standards like ISO 22000, HACCP and regulations like EU, FDA etc. depending on target markets and end uses.

Installation time ranges from a few hours for simple machines to a few days for complex systems. Commissioning and validation may take longer.

Most manufacturers provide extensive training programs, installation support, maintenance contracts and priority technical assistance through help desks and field engineers.

Yes, machines can handle materials specifically designed for meat such as high barrier films, MAP films and recyclable/ Biodegradable options depending on production needs.

Benefits include higher efficiency, output and accuracy, lower labor costs, product waste and safety risks, and extended shelf life due to optimized packaging solutions.