Nuts packing Machine

Sample bag

Machine Choice

Rotating Premade Pouch Snack Foods Packaging Machine For Nuts

Our Premade Pouch Packing Machine covers SS304 and adopts German/Japanese electronic components.Package up to 80 Bags/Min. We provide layout drawing services ,OEM service, and decent delivery time.

Vertical Form Fill&Seal Snack Packaging Machine

Hiqh quality Vffs Machine for snack, as a classic solution for various types of nut packaging, is also one of the choices. Package Up to 60 Bags/Min,Low price .If you have no special requirements for the appearance of the product packaging, then it is a good Choice.

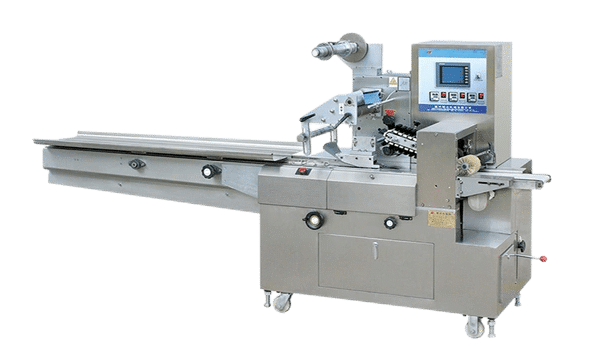

Nut Flow Wrapper Machine

Horizontal Flow wrapper, also as a classic solution for cookie packaging, is also one of the choices. Package Up to 290 Bags/Min, the servo Intelligent control,advanced PLC touch screen, run with low noise .If you have high special requirements for the accuracy of the product packaging, then it is a good Choice.

Ultimate FAQ Guide

- Maintaining quality attributes in nut packaging requires a holistic approach.

- Anoxia is critical, achieved through specialized sealing techniques. Advanced methods are used to evacuate intrusive oxygen through degassing nozzles or magnetic valves prior to closure.

- Alternatively, modified atmosphere packaging floods interiors with sterile preserving gases like nitrogen that displace air without altering its taste.

- Light-impermeable packaging materials like oxygen-scavenging films, metalized pouches, or cans protect against photo-oxidation threats.

- Humidity control through desiccant sachets or vapour-barrier laminates maintains ideal moisture levels and prevents rancidity.

- Ensure strict temperature management throughout the supply chain, from packaging to shipment to the sales floor, to protect heat-sensitive components.

- Integrated monitoring maintains environmental conditions to maximize shelf life by adhering to normative storage and distribution protocols.

- Automated leak detection during production ensures the package integrity for dependable protection in transit and beyond.

- Conveying: An entrance transports nuts from the loading point(s) to the downstream packaging stations.

- Weighing/Dosing: Precision scales for dose targets can be inserted into waiting receptacles such as bags or other formats.

- Filling: Controlled drop stations deposit levelled measures into closed packaging.

- Sealing: Heat, adhesive, or ultrasonic methods are used to bond packaging edges after product insertion.

- Coding: Inkjet arrays or labelling heads that have been freshly sealed with barcodes or other codes.

- Discharge: Outlet conveyors dispatch just-packaged items to subsequent handling, such as cartoning/case packing.

- Plastic films, papers, and coatings that are food-safe when handled and sterilized and meet regulatory requirements for indirect food contact are sufficient.

- Mono-materials streamline recycling without compromising barrier attributes when packaged properly.

- Affordable stocks like polyethene, polypropylene, and paper provide impermeability at optimal cost.

- Non-hazardous adhesives, inks, and sealants approved for such applications work without contaminating encapsulations.

- Standardized formats that are compatible with downstream applications and processes help with logistics optimization.

- Optical Inspection: Visible light and hyperspectral cameras inspect the fills to identify any defects, debris, or fragmented product anomalies before enclosing.

- Metal Detection: Critical control points throughout the line deploy precise detectors to screen shipments for tramp materials that could compromise packaging or pose risks.

- X-Ray Imaging: Where contamination intolerance applies, x-ray technology penetrates casing and nuts alike to detect even subtle foreign bodies before they are filled.

- Weight Inspection: Multi-head weighing authenticates the net contents, aligns with clearly marked labels, and reveals underfills or overages before distribution.

If the nut packaging machine is causing blockage issues during the packaging process, you can clean or adjust the discharge system, check if the conveyor channel is clear, etc. to fix it.

If you can not deal with it ,please contact us

Yes, some packaging equipment has an automatic label printing and affixing function that allows labels to be added during the packaging process.

Not only is label printing aesthetically pleasing, but it also complies with food safety laws. The general food manufacturers usually have labeling machines that are more expensive than the machines they use.

- These industrial-grade components are made from corrosion-resistant alloys and bearings, which help them last for 5-10+ years under normal operating conditions.

- Installing temperature and humidity controls in the packaging area can double the lifespan of equipment compared to unstable or extreme facilities.

- Consistent preventive maintenance, including lubrication, calibration, and systematic part replacement, as per OEM schedules, helps prevent degradation to rated performance. Download the Maintenance List Here.

- Operating at lower volumes can cause wear to increase, especially with heavy production.

- Proper cleaning protocols after a transition help keep the vulnerable internals safe from being damaged by debris over the long run.

- Basic weigh/fill: $15-100K

- Mid-range systems: $100-250K

- High-speed machines: $250K-500K

- Integrated lion systems: $500K-1M+

- It complies with occupational regulations to prevent contact with moving parts.

- To prevent operation with hazard-containing access panels, interlocks are used.

- Easily clean surfaces with Easy-Clean designs that don’t have any crevices where bacteria could hide.

- Clean-in-place systems thoroughly sanitize contact zones between runs.

- The changeover procedures minimize the risk of cross-contamination between SKUs.

- Enclosed enclosures with pre-filter air intakes and positive pressure prevent the contamination of airborne pathogens.

- Allergens are certified contained from nut surfaces and segregated from allergenic-free lines.

- Traceability protocols help us quickly recall products in case of issues.

The noise level of nut packing machines is usually between 60-80 decibels, depending on the machine model and operating condition.

Wenzhou BenGang Machinery is a well-established engineering company that combines R&D DPT, machine-producing DPT, marketing DPT, and after-sales team DPT.

We have been doing food, medical supplies, and commodity packing for over 10 years in China.

We can make and customize anything as needed.

I hope we can work together.