- Home

- Industries

- Granule

- Pet food

Pet food packaging Machine

Pet owners have high expectations for the quality and packaging of their pet’s food. Flexible packaging is a great way to stand out from other products on shelves.

The growing popularity of raw, natural, and organic pet foods requires better freshness protection. The Rotary Premade Pouch Machine can create custom-made pouches of any shape, perfectly packaging protein-rich pet foods and treats of various textures and temperatures. People use stand-up pouches with zippers to attractively display products as a marketing tool.

These pet food packaging machines can automatically weigh, fill, and seal pet food products into bags, pouches, or cans. We load pet food into the machine and weigh it in the appropriate size portions before packaging. The packs are sealed to keep them fresh and contain the product. Sealers sometimes replace air in the packaging with inert gases like nitrogen to prevent oxidation. These pet food packaging machines can handle high volumes and fill hundreds of packs per minute. They ensure consistent weights and minimize handling for efficiency and safety.

Machines can date stamps, apply use-by-date or print product details on packages. Automated packers can handle weighing, filling, sealing, and printing inline. They produce ready-to-use, pre-packaged products for retail sale.

Sample bag

Machine Choice

Rotating Premade Pouch Dog Food Packaging Machine

Our Premade Pouch Packaging Machine covers SS304 and adopts German/Japanese electronic components.Espeicial for stand up pouches.Package up to 80 Bags/Min. Our services include layout drawing, OEM service, and decent delivery time.

Vertical Form Fill&Seal Packaging Machine For Pet Food

The classic solution for Granule packaging, the pet food form fill and seal machine, is also one of the choices. Package Up to 60 Bags/Min,Low price .If you have no special requirements for the appearance of the product packaging. Then it is a good Choice.

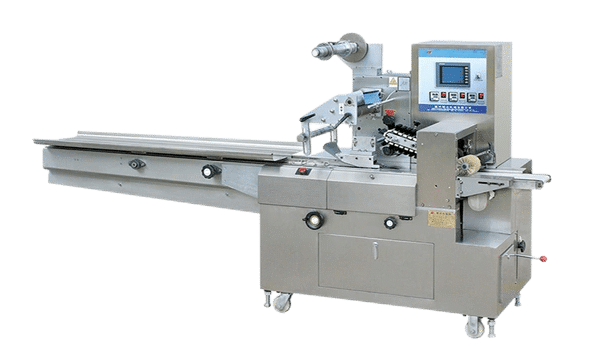

Flow Wrapper Machine For Dog food

Horizontal Flow wrapper for big granule , also as a classic solution for pet food packaging, is also one of the choices. Package Up to 290 Bags/Min, the servo Intelligent control,advanced PLC touch screen, run with low noise .If you have high special requirements for the accuracy of the product packaging, then it is a good Choice.

Ultimate FAQ Guide

The machines can handle all type of pet food. These include dog, cat, chicken,turtle food and dry pet food. The machines can handle dry kibble, wet food, and treats too.

To ensure accurate portions and airtight seals, different product types may need adjustments to feeding, weighing, and sealing systems.

A pet food packing machine automatically fills packages with pet food and seals the packages. It has everything you need for pet food, scales to measure portions, seals to close packages, and tools to move them.

- Programmable gravimetric fillers dispense calibrated rations into pending receptacles based on product bulk density profiles.

- Electronic weighing terminals can accurately measure dispensed masses and divert any over/underfilled items for rework while releasing compliant packages downstream.

- To keep your food fresh, seal your containers with hermetically sealed assemblies that bond the edges and fill them with flexible film, rigid plastic, or multi-ply cardboard.

- Robotic transfer units can shuttle just-sealed boxes between different filming, weighing, and sealing modules to maximize throughput.

- Advanced technologies use metal detection and X-ray inspection to find foreign objects, ensuring the safety of pets and their owners.

The bags automatically feed. They weigh everything accurately. You can seal them with heat or ultrasound, and they’re easy to clean. They can handle different bag styles and sizes. They are customizable.

The bags are automatically fed. They weigh everything accurately. They can be sealed using heat or ultrasound. They’re super easy to clean. They can handle different bag styles and sizes. They are customizable.

These food packaging lines are leading the way with innovative solutions for throughput needs.

- High-capacity bag loaders continuously feed blanks to fillers via vibration/suction feeding for non-stop production.

- Gravimetric scales that electronically monitor dispersed weights in real-time minimize overages/shortages by calibrating fill curves.

- Versatile sealing heads can support various closure styles, from basic heat to ultrasonic/pulse-impulse solutions for oxygen-barrier films.

- Clean-in-Place/Clean-out-of-Place systems make sanitizing between SKUs a breeze with automated disassembly/rinsing routines.

- Our modular designs can handle a variety of sack constructions, from gusseted to valves to pouches, using different tooling.

- With the programmable HMI interface, it’s easier to manage recipes when you have different products/targets that need parameter tweaks.

- Our sophisticated traceability software connects discrete serials with batch records for strict product accountability.

Automation leaders use precise and versatile packaging to reduce human factors in pet food quality.

Common packaging formats include bags (pillow bags, gusseted bags, block bottom bags, etc.), pouches (stand-up or doy pouches), trays, etc. Sizes can range from 1kg to 15kg.

Most pet food packaging comes with adjustable bag/pouch sizes, and sealing and handling systems to handle. make it easier to

Make sure to accommodate different pet food containers. You might have to make some changes for certain sizes. Specifically:

- The modular filling heads can easily swap to fit tapering/gusseted/pouch receptacles via dedicated tooling assemblies.

- Sealing modules come in all shapes and sizes, including pre-opened sacks, re-sealable pouches, convertible sealing jaws, rollers, and heating components.

- Repeatable bag handling systems have quick-change grippers and transfer devices to minimize reset times between stock-keeping units.

- Pressurized multi-head weigh fillers ensure accuracy regardless of vessel depth/diameter variability by optimizing filling curves.

- The routine adjustment capacity streamlines the transition between planned formulations packaged in unique envelopes.

With these customizable features, single lines can optimize throughput across a mixed product portfolio while still adhering to strict standards. The operator-friendly conversion between change parts capitalizes on the equipment utility.

The output can range from 30 to 100 packs per minute. Depending on package size, filling speed, automation level, number of filling stations, etc.

The slower models are good for small packages up to 30-50 packages per minute.

Can handle up to 50-80 packages per minute with a medium-power automatic line.

High-speed automatic lines can handle up to 80-100 packages per minute, depending on the package size.

Machines with multiple gauges and sealing stations can dispense various products quickly, dispensing over 100 packages per minute. These machines can handle the highest capacity.

The capacity depends on sealing speed, dosage, robot changeover, and emulsifier performance.

Small and medium-sized businesses prefer machines that can produce 30-80 pages per minute. Big businesses can choose production lines that can churn out 100 pages a minute or more.

Most machines have customization options like bag sizes, sealing types, labelling, etc. Some OEMs offer complete co-packing solutions for specific products.

The accuracy of Pet Food Bagging Machines can range from ±1-5% depending on the weighing system used. Combination weighers or multi-head weighers provide better precision for smaller packages. They also use volumetric filling.

People usually use heat sealing, ultrasonic sealing, or tape/glueing. Heat or ultrasonic sealing seals the airtightly to maximize shelf life. You can usually adjust the sealing times and temperatures.

- Heat sealing is a common method for creating a tight seal. It’s all about controlling time and temperature to achieve this. The goal of heat sealing is to extend the product’s shelf life.

- Ultrasonic sealing is better at keeping materials safe from heat and damage.

- Glueing or taping is great for quick output or when the food material is sticky.

- Newer equipment often has multiple sealing options, allowing flexibility in switching between methods. You can use both heat sealing and ultrasonic methods to adjust parameters to control seal quality for different materials online.

- By properly setting up sealing parameters, we can meet the needs of different bag/pouch designs and packaging materials, ensuring efficient airtight seals.

- Sealing methods give production lines powerful adaptability and flexibility to changing market demands.

Companies use heat sealing and ultrasonic sealing methods to make sure their packaging is top-notch and efficient.

Lintyco’s high-quality machines use sensors to detect problems like incorrect filling, and damaged packs, and prevent repacking of rejected items.

- These optical sensors can detect issues like under/overfilling in real-time to minimize waste.

- With sophisticated metal detectors and X-ray technology, we can identify foreign material contamination risks and direct nonconforming units to reject bins.

- Checkweighers measure individual unit weights to ensure consistent fill levels by diverting any above or below tolerance thresholds.

Designers create pet food packaging lines with smooth surfaces, stainless steel parts, and easy cleaning options to make cleaning easier. Some people have certifications for food processing.

Lintyco Machine follows strict hygienic design principles.

- Cleanable-in-place/clean-out-of-place designs ensure thorough cleaning and disinfection of contact areas between uses. Integrated CIP systems do that.

- Operators don’t have to worry about intensive manual washing and hygienic cladding prevents bacterial harborage on smooth surfaces.

- Stainless components can handle caustic washdown protocols between products.

- Quick-release carriages make validation quick and easy.

- Our programmable cleaning cycles disinfect every surface according to regulated standards using approved detergents.

- Leading machines get 3A or EHEDG certification to make sure they follow food safety regulations.

These hygienic packaging solutions address microbiological concerns by prioritizing uncompromised sanitation and effortless cleaning validation. Their certifications and design features lend transparency throughout the supply chain.

Lintyco machinery manufacturers prioritize worker protection and safety compliance. We usually use fancy packaging like emergency stops, protective guards, overload protection, anti-slipping parts, and dust control.

Specific function:

- Emergency stop circuits and guards keep the operators safe from moving parts.

- To prevent maintenance or jams, use interlocks.

- The components are tested by authorities like UL, CE, and CCC to ensure electrical and mechanical integrity. The low-voltage components are designed to minimize exposure risks.

- Machined surfaces have non-slip coatings to prevent slips and falls.

- Enclosures and ventilation systems help prevent airborne dust inhalation hazards.

- Our drive components are designed to shut down automatically in heavy loads to prevent damage or failure.

By adopting proactive ergonomic and safety-engineering practices, we create a risk-averse culture. Proper worker protection protocols are crucial for industry longevity.

Food bagging machines connect to conveyors, palletizers, robots, etc. to create a complete packaging line solution.

Power ratings usually go up to 200 to 500V, 25 to 100A, single or three-phase. Some systems require additional air supply, vacuum, or cooling depending on the configuration.

A standard pre-built machine usually takes a few hours to days to install. Installing, testing, and commissioning customized or integrated systems may take weeks.

Leading food packaging machinery suppliers believe that effective training is crucial in maximizing line uptime and return on investment. Their typical offerings include:

- We’ll have onsite commissioning and orientation by application engineers to ensure seamless production handoff.

- We’ll cover operating principles, sanitization procedures, and performance optimization techniques.

- We offer remote or on-call troubleshooting for unexpected issues via multimedia support portals.

- We have scheduled preventative maintenance programs and service agreements.

- You’ll have easy access to a huge inventory of spare parts.

Hope you have a great experience with Lintyco’s service!