- Home

- Industries

- Medical&Healthy

Packaging Machine for Medical&Healthy

Lintyco has been supplying packaging machinery to the pharmaceutical and nutraceutical industries for many years. From capsules to nutritional powders, we can provide packaging solutions for it all. We have installed many packaging machine solutions worldwide for the following projects:

– Capsules – soft and hard capsules, etc., requiring counting and filling machines, etc.

– Tablets – tablet packaging usually requires high speed in-line packaging machines for automatic sieving, counting and sealing

– Bulk powders – e.g. vitamin powders, nutritional powders, etc., requiring weighing and filling machines followed by sealed packaging

– Ointments – such as ointments, creams, etc., which require special filling and sealing machines

– Liquids – liquid products such as eye drops and cough syrup require high speed filling machines and form and seal packaging machines

– Suppositories – special counting and filling machines are required to fill and seal suppositories into bottles

– Medical masks – require automatic up and down conveyors to fill predetermined bags with mask sheets and then seal and cut them

Pharmacy Packaging Machine Choice

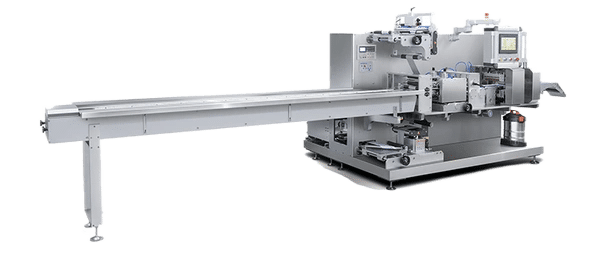

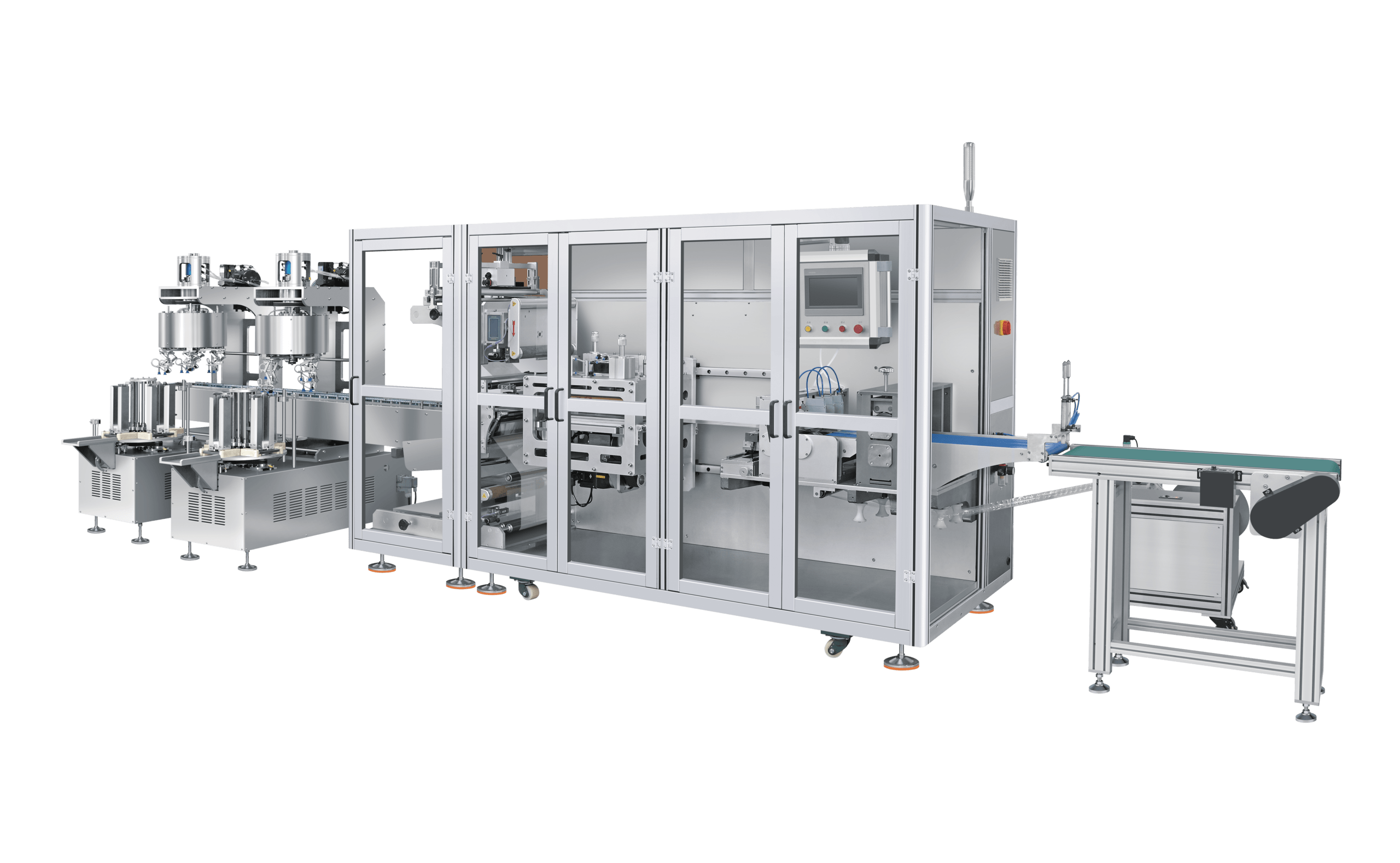

Horizontal Form Fill&Seal Machine For Medical Product

HFFS Packing Machine is particularly suitable for medical products. High precision, high speed and low product waste are guaranteed.Sold over 100 units during the COVID period

Horizontal Flow Wrapper Machine For Medical Products

Automatic flow wrappers are used to package different sizes of pharmacy products with robot arm . A pillow bag with a zipper is available, and up to 200per/min

Popular Bag Style

Playlist

Ultimate Guide

Common items include pills, capsules, strips, powders, creams, surgical kits, device components, syringes, etc. Some machines specialize in specific formats.

Fully automated machines integrate counting, filling, sealing, inspection and discharge. Semi-automatic models require loading/unloading assistance.

Popular formats include blister packs, pouches, bottles, jars, tubes, clamshells and other rigid or flexible containers in various materials.

Rates vary by machine size and complexity of parts packaged.Countertop models fill 50-500 units/hour. Floor/table models reach 500-5000+/hour for high-volume needs.

Common features include tamper-evidence seals, print/expiry tracking, weight verification, vision inspection, leak testing, serialized serialization etc.

Leading models are cGMP, ISO 13485, FDA approved for packaging pharmaceuticals, medical devices and IVD products meant for clinical use.

Most suppliers provide operator training, spare parts supply, preventive maintenance programs, retrofits and post-sales support.

Related Mecial&Healthy Material

Get A Free Quote Today

Get In touch

Don’t Compromise on Material Packaging. Customize with Our Team.

available from 10:00 – 19:00

Email [email protected]