- Home

- Industries

- Medical&Healthy

- Face mask

FACE MASK packaging Machine

Automatic face mask packaging machine is a machine that helps to pack face masks such as disposable masks, medical masks, N95 masks, KN95 masks, KF94 mask respirator masks, and flat masks. The machine can be divided into the flow wrapper and cartoning machine. The automatic packaging line is equipped with servo control and length of bag set and cut. It has a one-step setting which saves time and film. The packing speed is 30-100 Pkg/min. The machine is suitable for disposable surgical masks and can pack 1 piece, 5 pieces, 10 pieces, 20 pieces mask.

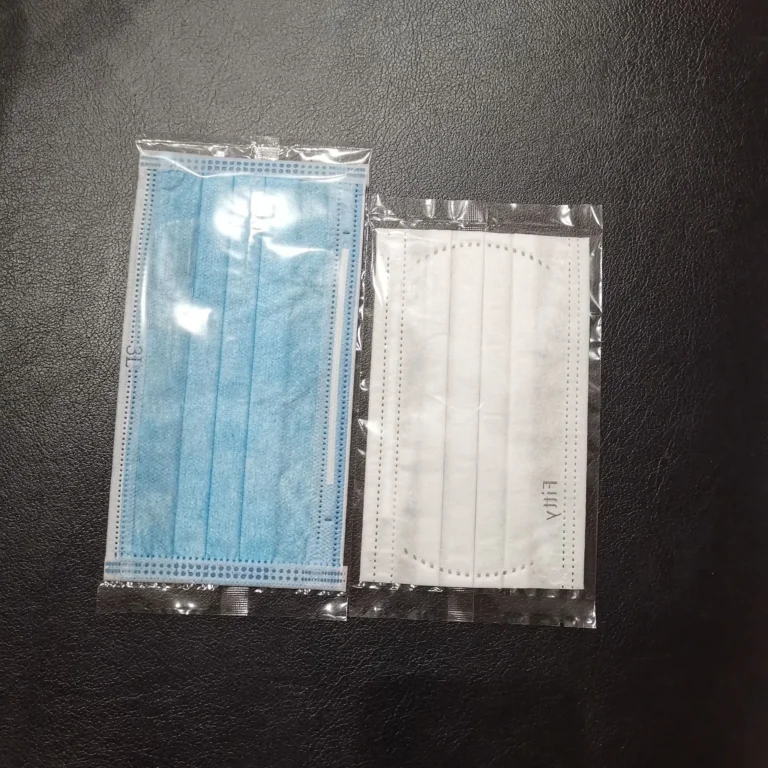

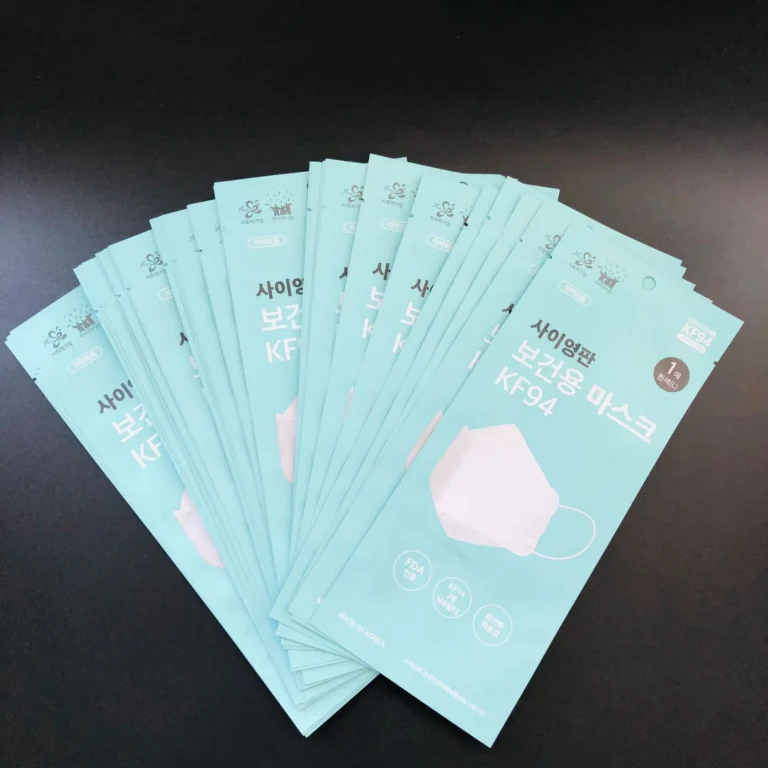

Sample Bag

Machine Choice

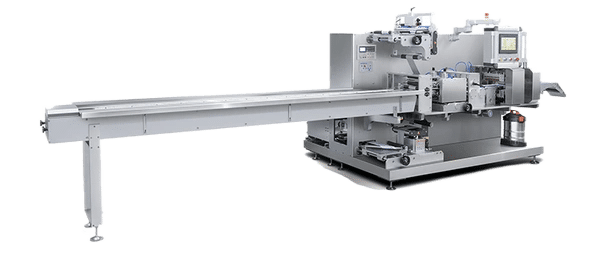

Horizontal Form Fill&Seal Machine For Face Mask

The advantage of using HFFS packaging machines is that they can efficiently package masks while still maintaining the quality and closure of the masks.Sold over 100 units during the COVID period.Speed up to 120 per/min Some additional adjustments can be made to ensure the quality of filling and sealing of the masks, depending on the particular material and shape of the masks. In general, special molds and perforators are required to coordinate the size and shape of the masks

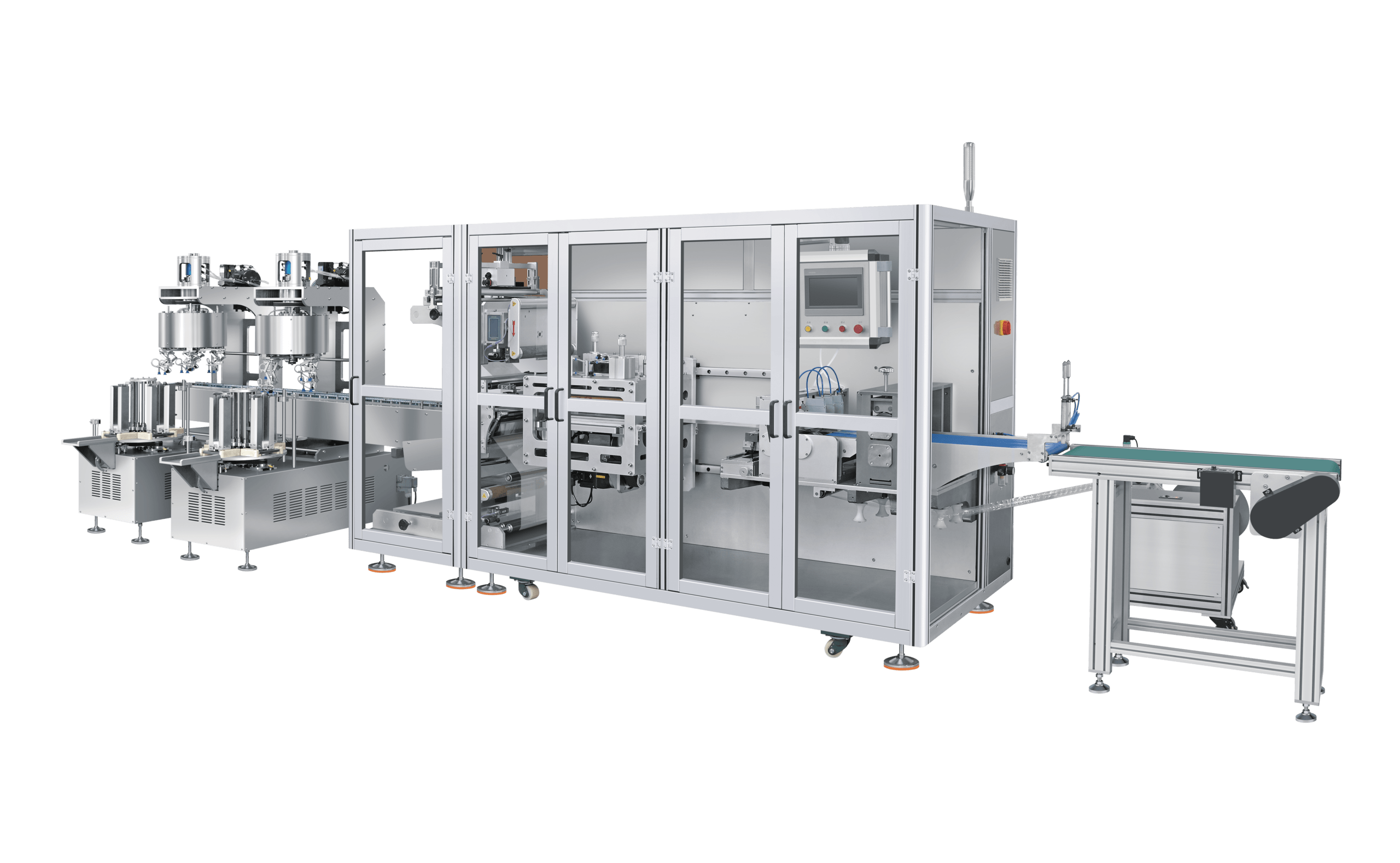

Face Mask Flow Wrapper Machine

Automatic flow wrappers are used to package different sizes of pharmacy products with robot arm . A pillow bag with a zipper is available, and up to 200per/min

Ultimate FAQ Guide

Automatic Face mask packaging machine is a machine designed specifically for hygienically packaging face masks. It can automatically package face masks into pouches, bags or other packaging materials.

Key features of a face mask packaging machine include: automated mask feeding, hygienic and sterile design, airtight and moisture-proof sealing, compatibility with different mask types and sizes, flexibility in packaging materials and closures, fast packaging speed, compliance with medical standards, etc.

Yes, face mask packaging machine can handle different types of face masks like surgical masks, N95 respirators and cloth masks in different sizes.

face mask packaging machine ensures hygienic packaging through a sterile and easy-to-clean design, automatic mask feeding that minimizes human contact, and airtight and moisture-proof heat sealing or ziplock sealing of the packaging.

Common packaging materials that can be handled include polyethylene (PE) pouches, polypropylene (PP) bags, paper bags, etc. The machine can apply heat seals, ziplock seals or adhesive seals to securely seal these packages.

Yes, Lintyco face mask packaging machine can accommodate different mask sizes, shapes and thicknesses through adjustable mask feeding and sealing mechanisms. It allows for quick format changes to switch between different mask types.

Yes, the packaging process can achieve airtight and moisture-proof seals when required to maximize mask protection and shelf life.

Advanced face mask packaging machines can be equipped with vision inspection systems to detect defects in mask sealing, positioning or contamination before packaging. Any rejected masks are removed automatically to ensure quality.

Routine maintenance like cleaning, part replacement (sealing jaws, forming collars, etc.) and lubrication is required for a face mask packaging machine. It needs to be done by trained technicians to sustain performance and compliance.

Automatic Face mask packaging machine can package up to 80-120 masks per minute for simple mask shapes. The speed varies depending on mask type, packaging material and other factors.

Yes, face mask packaging machine can work with different label placements – front, back, top, etc. It can also accommodate custom branding including printed packaging materials, labels and logos.

Yes, as long as the physical dimensions of the masks remain largely unchanged, a face mask packaging machine can handle masks with different performance levels or specifications. The packaging setting may need adjustments for masks with significant thickness or material differences.

Specialized or coated mask layers may require some adjustments to the sealing parameters and temperatures on a face mask packaging machine to achieve optimal sealing without compromising the mask integrity or performance. With testing, most mask types can be accommodated.

Yes, a face mask packaging machine can handle masks made of various materials such as non-woven polypropylene, melt-blown polypropylene, cotton, etc. Adjustments may be needed for some materials to optimize sealing and product integrity.

Skin type recommendations, treatment benefits and other product specifications can be printed on packaging or labels by a face mask packaging machine. The specific text, graphics and position are customized through the control interface for each product.