- Home

- Industries

- Powder

Powder Packaging Machine

Lintyco is well-versed in the field of food and Medical&Healthy packaging machines. In fact, more than 80% of the machines we produce are used in the food and health industry. We have developed packaging solutions for a wide range of items, including coffee powder, pepper powder, pepper powder, protein powder and other detergent powders. Even though we have unique cases for industrial chemistry.

Our robust packaging equipment is capable of handling food packaging projects of any size, from the smallest to the largest. Usually, the powder will raise dust. If the dust is very serious, we will equip you with a dust cleaner and lower the feeding position.

Powder Packaging Machine Chioce

Premade Pouch Powder Packaging Machine

Lintyco premade pouch packaging machine offers quick and easy adjustment for maximum customer convenience with a capacity of up to 80 bags per minute. In addition, we offer exceptional services such as layout arrangement drawings, OEM services and timely deliveries. If you have concerns regarding dust, we highly recommend considering this machine.

Vertical Form Powder Fill&Seal Packing Machine

Lintyco Vertical Form Fill & Seal Machine, a classic powder packaging solution, is one of the best choices for manufacturers who want packaging styles such as Pillow, Stick Pack, Sachet, Gusseted, Side Seal. Package Up to 60 Bags/Min,Low Price. Speed and affordability are the main reasons why these machines are still in use.

Popular Bag Style

Ultimate Guide

Most powder packagers can handle food-grade products like spices, baking mixes, flour, cereal, coffee/tea, snacks etc. Industrial models manage chemicals, minerals, pet food, supplements etc.

Thoughtfully Engineered for Productivity

An intelligently designed control panel allows efficient, automated operation with minimal oversight. Independent circuit boards for pneumatic and electrical systems ensure stable, quiet function. Fully automatic packaging expedites output.

User-friendly Touchscreen Interface

A PLC display can be programmed via an intuitive interface for adjustable speed, filling length and more.

Quality Packaging Assured

Dual belts with large wheels form bags with pleasing aesthetics. Servo film feeding provides accurate positioning. Rear-mounted film dispensers simplify replenishment. An enclosed design shelters the process from contamination.

Customization is Also an Option

We welcome opportunities to tailor equipment per specific customer needs through original equipment manufacturing partnerships.

Common filling methods include gravity, loss-in-weight or gain-in-weight systems. Auger/screw fillers are best for dense or cohesive powders. Gentle compression fills light/fluffy powders neatly.

1. Bulk Powder Loading

The powder is loaded from a large hopper or silo and fed into the machine for packaging.

2. Powder Feeding

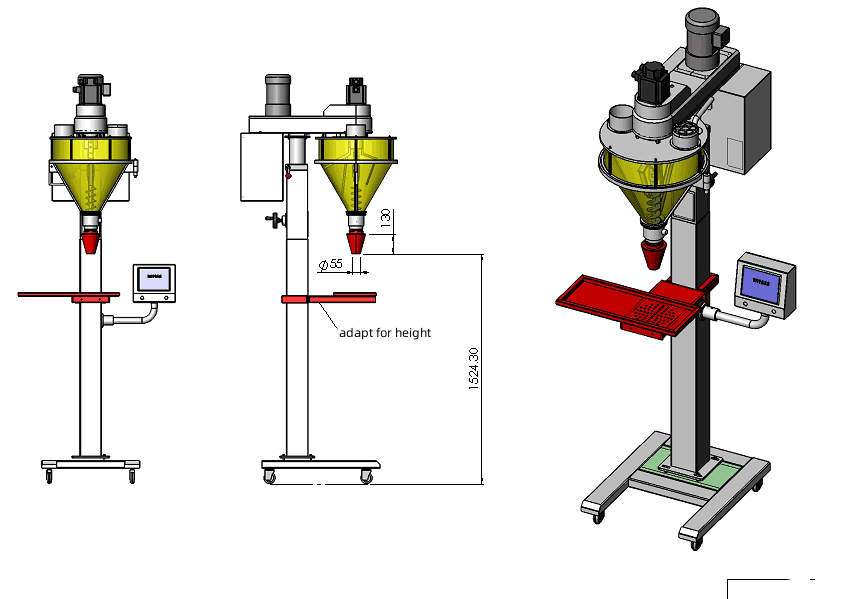

An auger, vibrating tray, or other mechanism precisely meters and feeds the desired amount of powder.

3. Dosing

The powered is dosed/weighed using loss-in-weight or gain-in-weight systems to ensure accurate fill quantities.

4. Filling

Powder is transferred into packages like bags, pouches, jars through funnels, sliding shelves or injection filling. Gentle filling minimizes powder disturbance.

5. Sealing

Open packages are heat sealed, adhesive sealed or crimped closed depending on material type. Some machines form, fill and seal in one step.

6. Inspection

Controls check fill levels, seal quality, and package integrity through metrics like weight, speed cameras, leak detectors.

7. Discharge

Completed packages are smoothly discharged via conveyors for further handling like overwrapping or boxing.

8. Automation

Advanced machines integrate all steps for high-speed, continuous production with minimal human intervention.

So in summary – powder is metered, dosed, carefully filled, sealed, inspected and discharged in an automated process.

Typical packaging formats are bags, cartons, drums, boxes, pouches, bottles/jars. Premade bags or form-fill-seal options. Small machines do pouches/sachets.

Lintyco have integrated dust control with features like mesh barriers, enclosures, bag tie systems and collector bins to maintain hygiene.if you want better we equip you with a dust cleaner and lower the feeding position.

Fully automated systems integrate weighing, filling, closure/sealing and discharge conveyors. Semi-automatic models require bag loading/unloading assistance.

Here are some tips for maintaining a powder packing machine:

Clean thoroughly on a regular schedule. Removable parts can be washed while the machine is dismantled for deep cleaning.

Inspect and lubricate moving parts as specified. Apply lubricant sparingly to avoid contamination.

Check belts, wheels and chains for wear. Tighten or replace components as needed.

Calibrate powder dosage systems periodically. Adjust settings if fill weights drift over time.

Inspect seals and empty residue after use to prevent caking or deposits.

Protect electronic components from dust and moisture. Clean printed circuit boards carefully.

Validate safety systems such as light curtains and pressure mats are functioning.

Follow engineering specifications for maintenance intervals and spare part replacement.

Train operators on cleaning procedures and proper lubrication/adjustment techniques.

Consider contracting preventive maintenance support to catch issues early.

Review motor/bearing wear over the long-term and replace as lifetime hours are reached.

Maintain product changeover records for parts that must be specific to the item packed.

Download Your Maintence List here

A machine will depend on the configuration, the degree of automation and the requirements for speed. Configuration can be Chinese domestic products or German-Japanese accessories, such as Omron, Siemens. The degree of automation can be semi-automatic, can also be fully automatic, fully automatic inside there are higher precision requirements. There are many programs to reach the speed, depending on the requirements of our customers.

Bengang Packing Machinery Co., Ltd has accrued extensive expertise over many years as a leading manufacturer and supplier of packaging machinery. We are committed to offering equipment of excellent quality along with professional service and competitive pricing for our customers. Prior to shipment, photos and videos are provided. Feedback is also welcomed to ensure continuous improvement. Post-sale support is a priority, reflecting our dedication to building strong partnerships. This commitment is evidenced by our growing global customer base and increasing international orders. Customizing solutions to meet specific needs is equally valued. Please contact us to learn more about customized options or standard models that align with your requirements. We look forward to discussing how we can assist with your packaging needs.