introduzione

Hai problemi con la tua attività di dolciumi? Vuoi rinnovare la tua fabbrica?

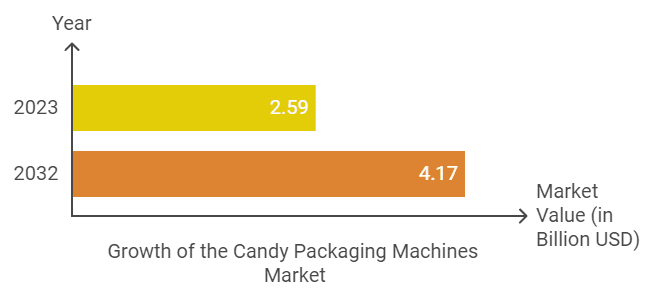

L'industria dolciaria utilizza una varietà di macchine per l'imballaggio per soddisfare le esigenze di produzione e le preferenze dei consumatori. Il mercato globale delle macchine per l'imballaggio di dolciumi è stato valutato a circa $2,59 miliardi nel 2023 e si prevede che crescerà in modo significativo, raggiungendo circa $4,17 miliardi entro il 2032, con un tasso di crescita annuale composto (CAGR) di 5.46% nel periodo di previsione dal 2024 al 2032.

Tipi di macchine per il confezionamento di caramelle

L'industria dolciaria impiega vari tipi di macchine confezionatrici, ciascuna progettata per soddisfare specifiche esigenze di confezionamento e tipologie di prodotto. Ecco i tipi più popolari di macchine confezionatrici per dolciumi:

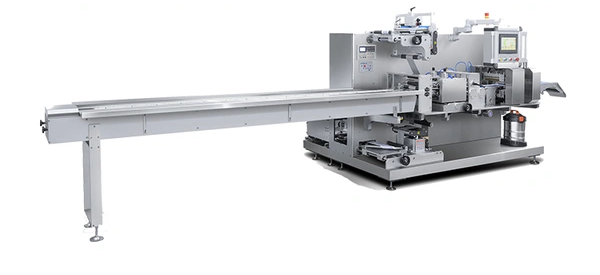

Macchine confezionatrici a flusso continuo

Le macchine flow-pack sono ampiamente utilizzate per caramelle confezionate singolarmente, offrendo una tenuta stagna che ne preserva la freschezza. Sono particolarmente efficienti per linee di produzione ad alta velocità.

Macchine insacchettatrici

Le macchine insacchettatrici riempiono e sigillano sacchetti con caramelle, spaziando da semplici modelli manuali a sistemi automatizzati avanzati. Possono gestire vari stili di sacchetti, tra cui sacchetti a cuscino e sacchetti stand-up.

Macchine avvolgitrici a spirale

Ideali per i dolciumi che richiedono estremità attorcigliate, queste macchine offrono un metodo di confezionamento tradizionale ma efficace.

Macchine Astucciatrici

Utilizzate per confezionare caramelle in scatole pieghevoli o rigide, le macchine astucciatrici massimizzano l'efficienza nella produzione di grandi volumi.

Macchine per il confezionamento in blister

Garantiscono un'eccellente protezione contro i fattori ambientali e sono particolarmente utili per i prodotti che richiedono un imballaggio antimanomissione.

Macchine confezionatrici termoretraibili

La macchina termoretraibile crea una tenuta stagna attorno ai prodotti, migliorandone la protezione e la presentazione. Sono spesso utilizzate per imballaggi alla rinfusa.

Macchine per l'imbottigliamento e l'invasettamento

Progettate per confezionare caramelle in barattoli o bottiglie, queste macchine si adattano a contenitori di varie dimensioni e forme.

Macchine per imballaggio in buste ad alta velocità

Sono adatti per confezionare più caramelle in un'unica busta, soddisfacendo così la richiesta di praticità dei consumatori.

Macchina per caramelle Tendenze del mercato

Il mercato delle macchine per il confezionamento di caramelle sta vivendo una crescita dovuta a diverse tendenze:

Automazione

L'aumento delle tecnologie di automazione, tra cui l'intelligenza artificiale e la robotica, sta migliorando l'efficienza e riducendo i costi di manodopera nelle attività di confezionamento dei dolciumi.

Sostenibilità

La domanda di soluzioni di imballaggio ecosostenibili è in crescita e spinge i produttori ad adottare materiali e pratiche sostenibili.

Personalizzazione

I marchi sfruttano le tecnologie di stampa digitale per creare imballaggi personalizzati che rispondano alle preferenze dei consumatori, migliorando il coinvolgimento del marchio.

Aziende leader nelle macchine per il confezionamento di caramelle

Precedentemente nota come Bosch Packaging Technology, Syntegon è un'azienda leader nel settore del confezionamento di caramelle, che offre un'ampia gamma di soluzioni di lavorazione e confezionamento per vari tipi di caramelle, tra cui caramelle gommose e gelatine. Si concentra su sistemi di produzione intelligenti e flessibili ed è riconosciuta per il suo impegno verso la sostenibilità.

Con sede nei Paesi Bassi, Tanis è specializzata in linee di produzione di caramelle gommose e gelatine. Offre soluzioni complete che coprono tutte le fasi della produzione di caramelle, dalla preparazione al raffreddamento, rendendola un fornitore chiave per molte aziende dolciarie a livello globale.

Un produttore con sede nel Regno Unito, Loynds fornisce macchinari per dolciumi e cioccolato da oltre 30 anni. Offre una varietà di macchine su misura per piccoli e medi produttori di caramelle, tra cui macchine insacchettatrici e linee di produzione complete.

Con sede in Cina, Lintyco è un'azienda tecnologica leader nella rivoluzione della tecnologia di imballaggio. Negli ultimi dieci anni, ha costantemente innovato, eccellendo in particolare nelle macchine per l'imballaggio a quattro lati, classificandosi tra le prime cinque a livello nazionale. Aumentare l'efficienza produttiva dei clienti e ridurre i tassi di errore sono sempre stati gli obiettivi a cui si sforzano.

Questa azienda statunitense si concentra sulla progettazione e produzione di apparecchiature di lavorazione per il settore dolciario. Fornisce una gamma di macchine per caramelle dure, gommose e liquirizia, comprese soluzioni di cottura e confezionamento.

Nota per le sue macchine di alta qualità per la produzione di cioccolato e dolciumi, Chocotech ha sede in Germania. Offre soluzioni tecnologiche avanzate per la produzione di caramelle, tra cui macchine per temperaggio e ricopertura.

Multinazionale svizzera con una lunga storia nei macchinari per la lavorazione alimentare, Bühler fornisce attrezzature per la produzione di cioccolato e dolciumi. La loro competenza in ingegneria aiuta a migliorare l'efficienza produttiva per i produttori.

Specializzata in macchinari per l'imballaggio e l'astucciamento, Delkor si è affermata come leader nel mercato del confezionamento dei dolciumi, concentrandosi su soluzioni di imballaggio pronte per la vendita al dettaglio che soddisfano le moderne esigenze dei consumatori.

Queste aziende sono riconosciute non solo per i loro macchinari innovativi, ma anche per la loro capacità di adattarsi alle mutevoli tendenze del mercato e alle esigenze dei clienti nel settore dolciario.

Conclusione

L'industria dolciaria si affida a una vasta gamma di macchine per il confezionamento, studiate su misura per vari tipi di dolciumi e scale di produzione. La crescita continua in questo settore riflette tendenze più ampie nel comportamento dei consumatori e nei progressi tecnologici, sottolineando l'importanza di soluzioni di confezionamento efficienti ed efficaci.

Ora che conosci i tipi di macchine confezionatrici per caramelle e i produttori più noti, se hai domande puoi contattarci.