In the grain industry, efficient and reliable packaging machines are vital to business operations. Grain manufacturers pack grain products into bags or boxes through semi-automated and fully automated methods to convey them globally for sale. In this article, we will delve into the future trends of grain, how bagged grain packaging machines work, key selection points, and guide business customers to choose the most suitable machine for their needs.

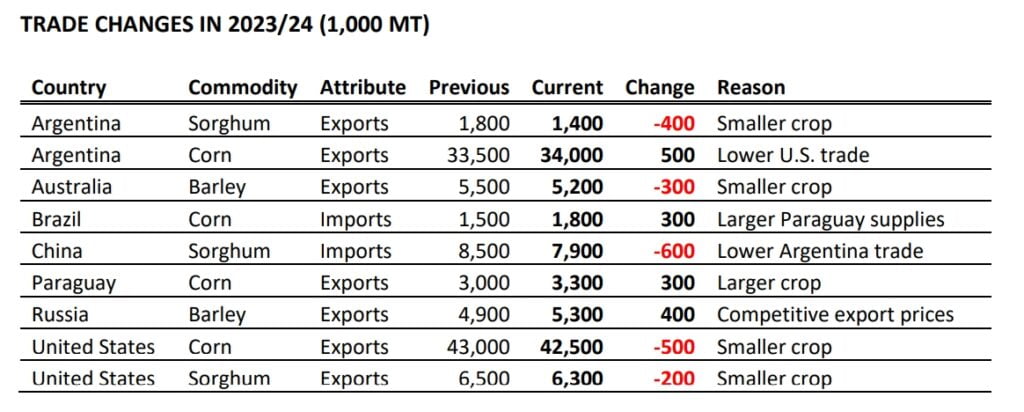

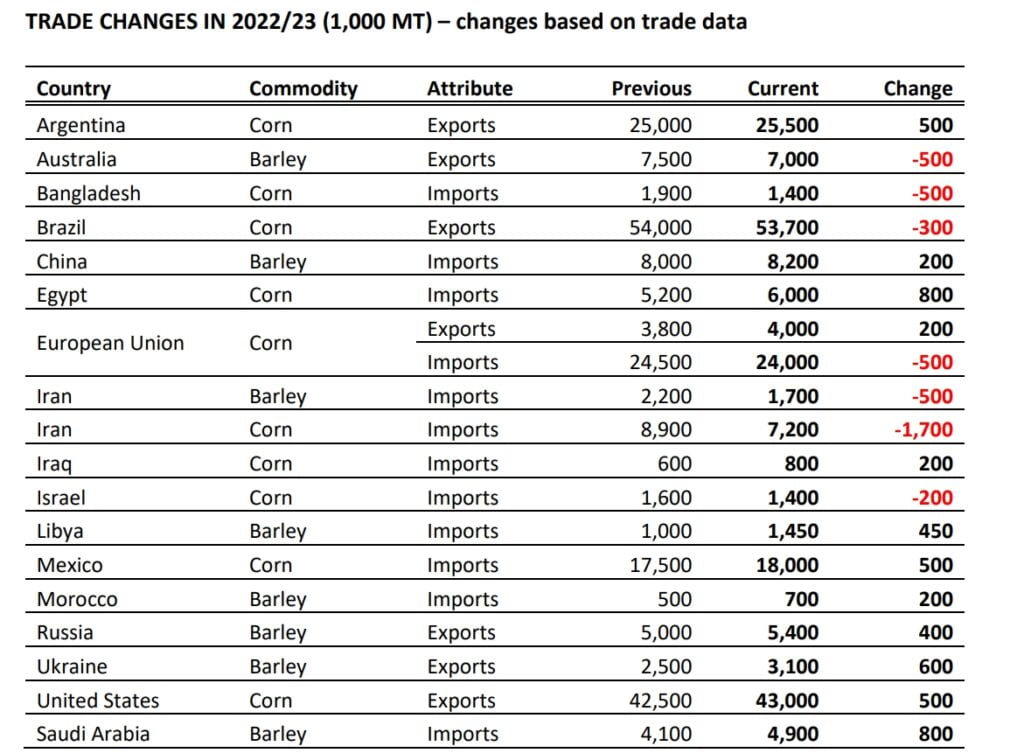

Corn and Grain Global Exports and Imports

Overall from the data, grain is still holding steady. The overall prices are expected to rise because of more instability. For large corporations and startups, costs and profits are paramount

AUTOMATIC PACKING MACHINES for Sale

Packaging machines abound in the market, and there is a wide variety of them to choose from. Some of the ways in which automatic packing machines are classified are:

Primary or secondary:

This can be referred to as inner and outer packaging. Primary or inner packing is the packaging in contact with the product while secondary or outer packaging refers to the second layer of packing and includes machines such as wrapping machine, cartoning machine, box filling machines, shrink wrap machines, etc.

Single-function or multi-function:

Single-function packing machines serve only one function in the packing process such as filling or sealing.

Multi-function machines perform multiple functions. For example, modern VFFS machines or HFFS machines automatically form the pouch into various formats like a pillow, gusset, sachet, quad seal, stick pack, etc. Then fill the product, seal it, and cut the pouch.

Automatic or semi-automatic:

Multi-function machines are usually fully automatic machines and are generally more expensive. If you have a limited budget or smaller output targets, you could consider a semi-automatic packing machine.

- Working Principles of Pouch Grain Packing Machines:

Grain packing machines are automated equipment designed to efficiently fill grain products into packaging bags and perform functions such as sealing, weighing, and coding. The primary workflow of these machines involves the following steps:

a. Conveying and Positioning: Grain is conveyed to the packing machine through a transportation system, while a positioning device ensures accurate placement of the grain into the packaging bags.

b. Weighing and Filling: The packing machine automatically measures the grain based on the set weight requirements and fills it into the packaging bags.

c. Sealing and Coding: Once the filling process is complete, the packaging bags are sealed, and additional information such as dates and batch codes can be printed on them.

d. Discharging and Arranging: The filled bags are neatly arranged and discharged through an output system.

Key Considerations for Grain Packing Machines

Packaging speed: each enterprise requires different packaging machine models and speeds. For instance, if you’re making face masks, you can bag 30 packages a minute. To increase output, we need to choose a machine that can produce more than 30 packages per minute.

Packaging range: Different grain particle sizes have different bag sizes and weights. For instance, modern packaging machines are flexible and can freely switch between multiple bag sizes. The maximum and minimum range of your products should be provided to facilitate fast and accurate model provision.

Degree of automation: Packaging machines with a high levels of automation can increase productivity and reduce labor costs. Consider the level of automation of the packaging machine, such as automatic feeding, automatic sealing and other functions. For instance, some factories can choose semi-automatic machines that only need to do sealing or feeding when the output is enough. Large factories should be equipped with fully automatic production lines.

Freshness: The effectiveness of the sealing determines the product’s insurance, so choose the best sealing method to maintain its freshness and long shelf life.

Sustainability: Modern packaging machinery not only offers good return on investment (ROI), but is also beneficial for the environment. They use fewer materials and have lesser greenhouse gas emissions.

The Success Story of Siemer Milling Company

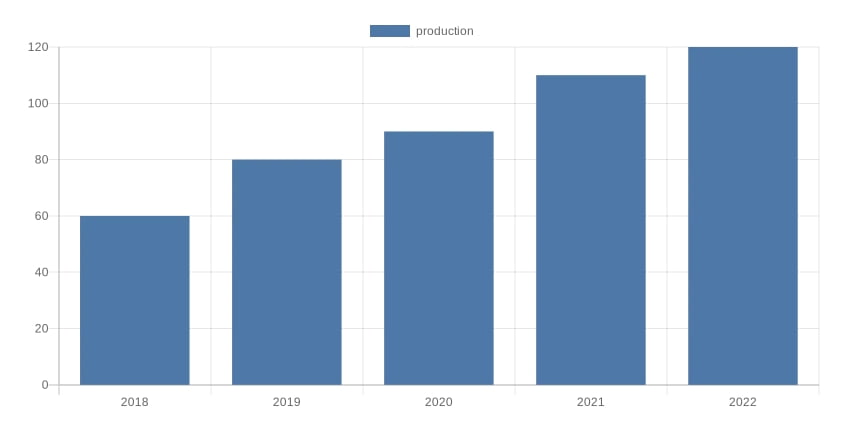

Let’s consider the case of Siemer Milling Company. This company achieved significant results after implementing a high-speed grain packing solution.

Siemer Milling Company starts in the field with the finest, responsibly grown wheat. Our community roots are built on long-standing relationships with our farmers. Our bonds, along with our history of innovation, lead to wholesome quality that our customers can trust.So they carefully consider their production demands and packaging range when selecting a packing machine. They chose an automated packing machine capable of filling up to 100 bags per minute, which met the company’s high-volume requirements. The machine is equipped with a PLC system that can easily and safely control of the entire packaging process. Temperature control is more safe and more effective through a PID controller. The packaging materials are controlled by servo motors, which are accurate and able to work continuously at high speeds with almost negligible packaging errors.

The Siemer Milling Company, they embraces our responsibility to our customers in providing a safe food product. By integrating the grain packing machine, the company has improved efficiency and stability in their packaging production line. As a result, in the years that followed, production rose and market share increased.

FAQ

1.What Are the Essential Features to Look for in Grain Packing Machines?

Answer: When selecting grain packing machines, consider features like packaging speed, packaging range, degree of automation, and the machine’s ability to maintain product freshness. Also, assess the sustainability and environmental impact of the machine.

2.How Can Grain Packing Machines Improve Product Freshness?

Answer: The effectiveness of sealing in grain packing machines is crucial for maintaining freshness and extending shelf life. Choosing machines with superior sealing capabilities is essential for preserving grain quality.

3.How Can Lintyco Packaging Assist in Selecting the Right Grain Packing Machine?

Answer: Lintyco Packaging offers expert consultancy in selecting the right grain packing machine tailored to your business needs. We provide machines that ensure efficiency, sustainability, and high-quality packaging, supported by our extensive industry experience.

Automatic Packing Machines From Lintyco

Lintyco is a pioneer and leader in automated grain packaging machines and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.