- Thuis

- Industrieën

- Medisch & Gezond

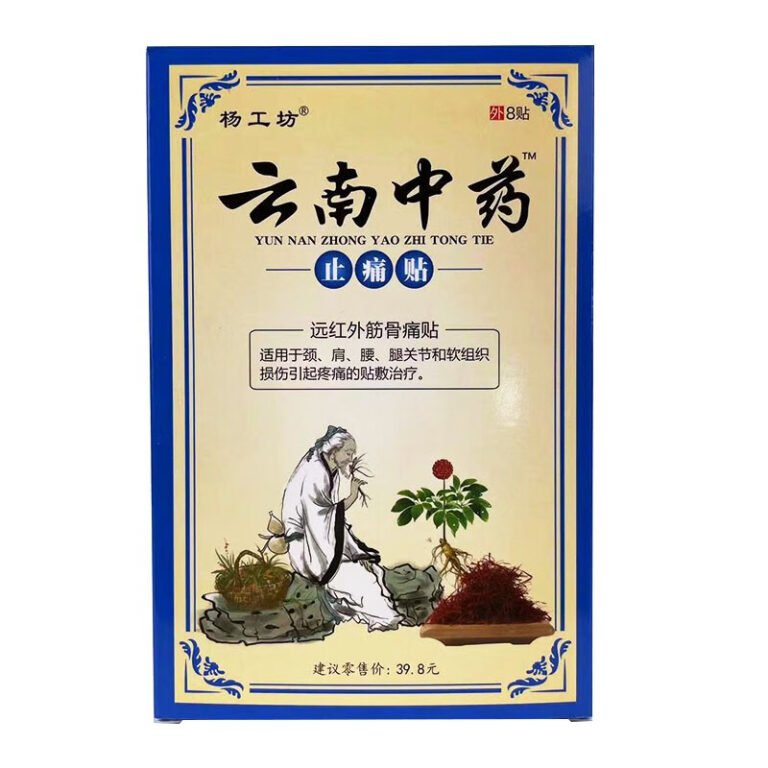

- Pijnstillende pleister

Pain relif patch packaging Machine

When you need to efficiently and reliably package your PAIN relief patch products, we recommend using our improved HFFS machine. Lintyco HFFS machine is capable of quickly and accurately packaging PAIN relief patches of different sizes into airtight sealed pouches that are resistant to moisture, heat, light, and harmful substances, ensuring safe delivery to your consumers.

Lintyco improved HFFS machine features a high degree of automation and intelligent control systems to significantly increase your manufacturing productivity, allowing for superior packaging quality. Choose our HFFS machine, and we guarantee to provide you with exceptional product quality and outstanding production efficiency to help you stay ahead in a competitive market environment.

Steekproef

Machinekeuze

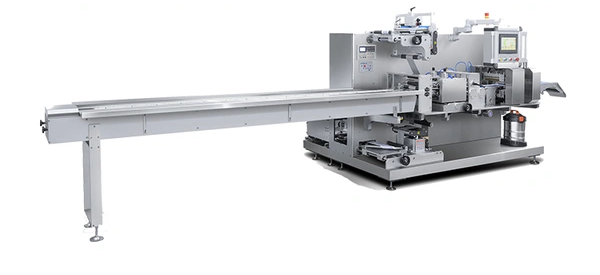

Horizontal Form Fill&Seal Machine For Pain Relif Patch

Automatic pain relief patch packaging machine are used to package different sizes of pain relief patches and can be customized to meet the specific needs of different varieties of patches.Up to 180per/min

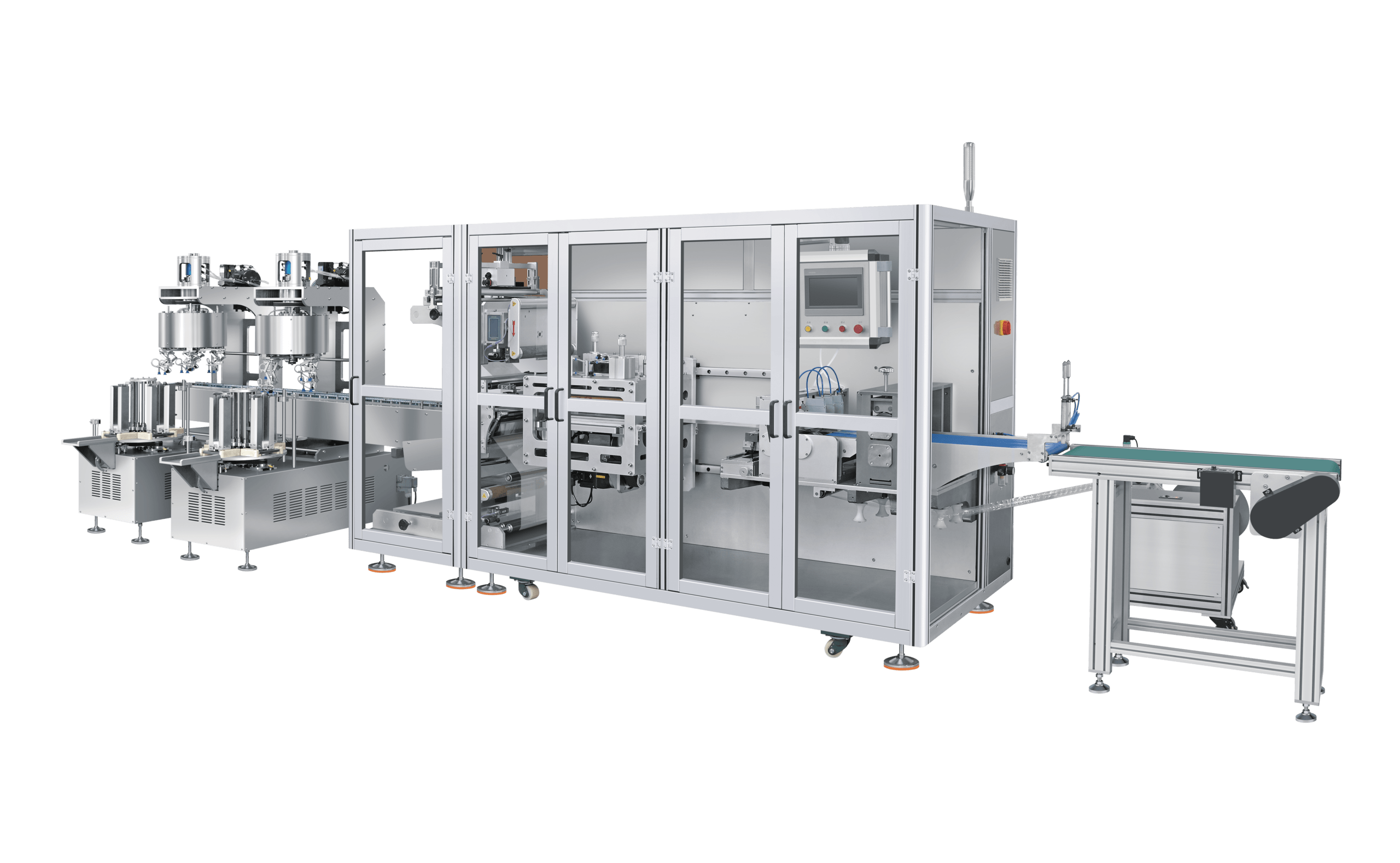

Horizontale flowwrappermachine voor medische producten

Automatische flowpackers worden gebruikt om verschillende formaten farmaceutische producten te verpakken met een robotarm. Er is een kussenzak met ritssluiting beschikbaar, en tot tot 200 per/min

Veelgestelde vragen

Various types of pain patches, including different shapes, sizes and materials.

Any type of pain relievers can be packaged on this machine. It can accommodate all shapes, sizes and materials of pain relievers. It can accommodate all shapes, sizes and materials, including some of the unusual shapes you see on the market.

The speed of this machine depends on the number of sheets per minute. You can adjust the speed according to your needs. Usually it is 100-180 packs per minute.

Only one operator is needed. If you need faster packing speed, you can consider adding additional operators or adding packing lines.

This machine requires regular maintenance, including cleaning, replacing parts, adjusting the drive system, etc. It is recommended that you check the owner’s manual for information about the machine. You can refer to the user manual for maintenance requirements.

The machine is warranted for one year. During this period, if you find any manufacturing defect or malfunction in the machine, we will make a video repair or arrange an engineer to fix it for you.