Liquid Premade Pouch PackagingMachine

- Automatic rotary premade spout stand pouch liquid detergent packaging Machine

- For stand pouch, doypack pouch,zipper pouch, spout pouch,normal pouch

- 30 days delivery time

- Free Factory Tour by Video

- Get Your Product PDF

Automatic liquid premade pouch packaging machine

Related Product Click To Check

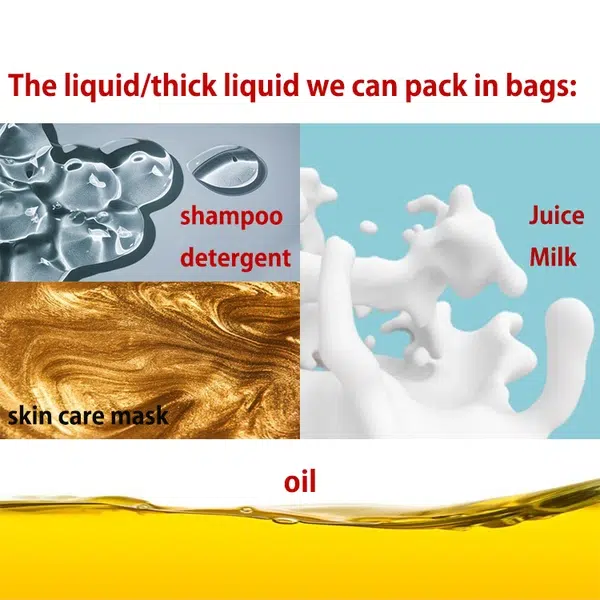

Liquid Premade Pouch Filling Machine specially for detergent, Yellow rice wine, Soy sauce, Rice vinegar, Juice, Tomato paste, Peanut paste, Fruit paste, Chili sauce, Bean sauce, etc.

Summery |

|||

|

1. Easy to change bag size and bag type.

2. Easy to adjust Printer range. 3. Machine optoelectronic system can check bag,material filling and sealing situation to avoid failure. 4. Stable worktable with low noise and long life as the bottom drive system. 5. High bag opening effective and low machine failure rate. 6. Sample wiring arrangement with high quality electronic components |

|||

Model&Parameters |

|||

|

LTC8-200

|

LTC8-260

|

LTC8-300

|

|

|

Bags size

|

W:80~210mm L:100~300mm

|

W:120~250mm L:100~400mm

|

W:200~300mm L:100~400mm

|

|

Bag type

|

Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag

|

Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag

|

Flat bag. Stand-up bag. Zipper bag. Doypack zipper bag. Spout bag

|

|

Filling Volume

|

30 – 1900g depending on type of products

|

30-2000g depending on type of products

|

100-2500g depending on type of products

|

|

Capacity

|

25-60 bags/min for different material and different bag

|

25-60 bags/min for different material and different bag

|

25-60 bags/min for different material and different bag

|

|

Dimension

|

1.140*1.500*1.560m

|

2.46*1.83*1.46m

|

|

|

Weight & power supply

|

1400kgs/1500kgs/1600kgs-1800kgs 380v 50HZ 3P 2.5kw-5kw

|

||

|

Compress air requirement

|

0.6-1m³/min supply by user

|

||

|

Working flow

|

1. Bag feeding

2. Date printing 3. Zipper opening 4. Bag opening 5. Material filling 6. 2th material filling 7. Buffering or function 8. 2th sealing and output |

||

Sample Bag

Attention: If the bag sizes fall outside of the specified range, we will offer customization options to fulfil any unique size requests.

- Zipper/Resealable/Ziplock bag packaging —— between zipper and bag mouth distance at least 2.5cm.

- Gusset bag packaging —— bag gusset width within 50mm, if the bag mouth is too small the products can’t fill completely, can’t do packing.

- Spout bag packaging —— spout at the side of the bag, sealing sizes at least 50mm.

- Pallet bag packaging —— pallet in bags, pallet length lower bag mouth at least 3cm.

Auxiliary Equipment

FAQ

|

Q1: Are you a factory or trading company?

|

|

A: We have 10+ Long Years Of Manfacturing&Trading Combo With Quality

|

|

Q2: Can you guarantee your quality?

|

|

A: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time. You can be assured of our production completely.

|

|

Q3: What should I do if we are not able to operate the machine when we receive it?

|

|

A: Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have a professional after-sale group on the customer’s site to solve any problems of liquid pouch filling machine.

|

|

Q4.What are the payment terms and trade terms for new customers?

|

|

A: Payment terms: T/T, L/C, D/P, O/A, Western Union etc.

|

Package&Delivery

Skyrocket Your Business with Lintyco

VIP Treatment, Top Brand Configuration, Miss it Forever or Get it