Vacuum Packaging

- Home

- Packaging EQUIPMENT

- Vaccum Packaging Machine

Vaccum Packaging Machine

Vacuum packaging refers to the technique of removing air from a pack prior to sealing and it predates the use of gases as a means of food preservation. Its principal purpose is to remove oxygen by pulling the packaging material into intimate contact with the product.

It is a good system for distribution and long-term storage of fresh meat cuts, providing longer product life and, if chilled and handled properly, allowing meat color to return to a highly desirable bright red or bright pink form in retail offerings, where retail cuts are packaged with oxygen-permeable film.

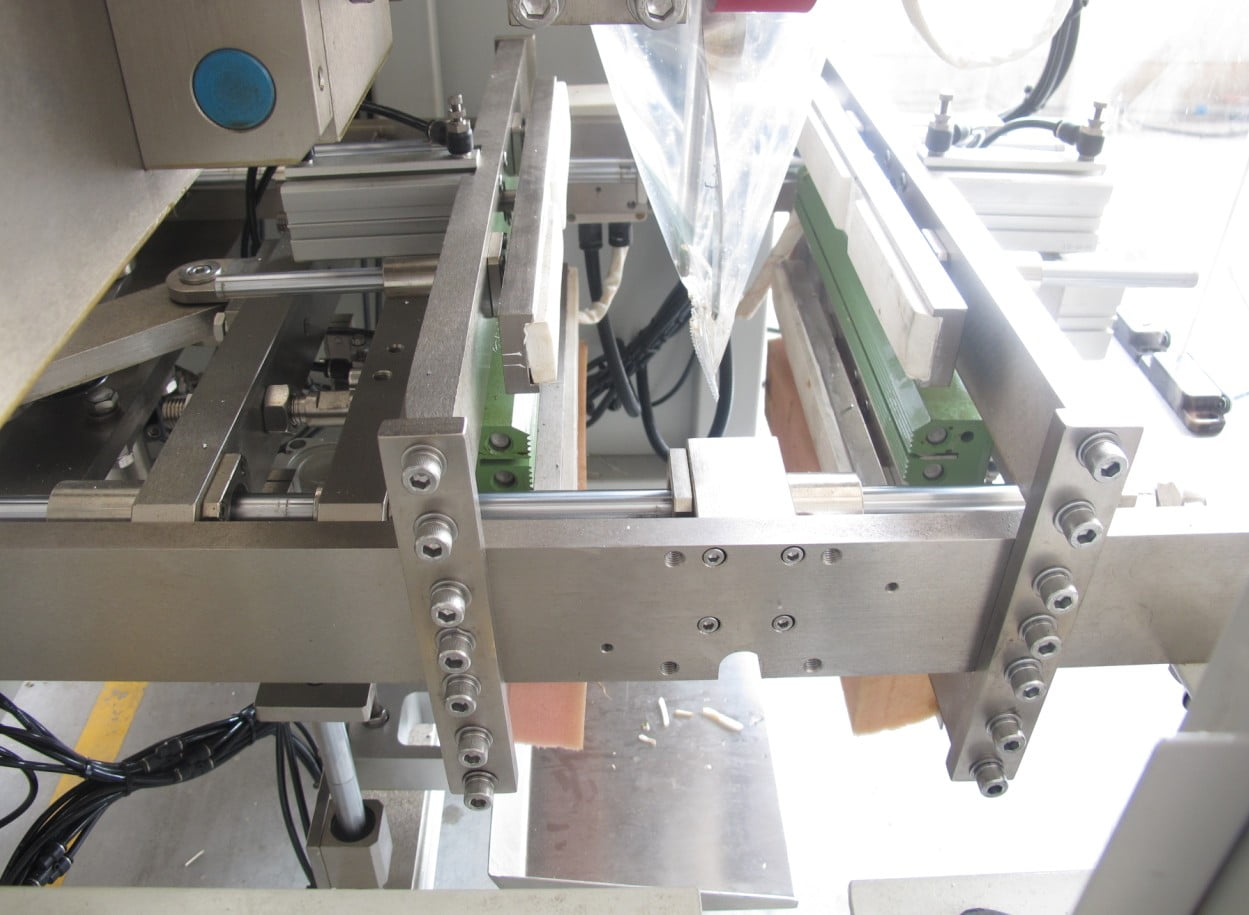

Automatic Vacuum Packaging Machine Choice

Depending on the product, different vacuum packaging technologies are suitable for packaging foodstuffs and other products. Our Equipped oil-lubricated rotary vane vacuum pumps and dry screw vacuum pumps are perfectly matched to the needs of the food industry and are continuously being further developed together with our customers. Discover our series for the packaging industry.

DOYPACK POUCH PACKAGING MACHINE

Our Premade Pouch Packaging Machine covers SS304 and adopts German/Japanese electronic components.Packing machine can work with different filler to pack solid, powder and liquid.Package up to 80 Bags/Min. It is best choice in the long time.

Vertical Form Fill&Seal Packing Machine

Vertical Form Fill & Seal Machine, as a classic solution for Granule packaging, is also one of the choices. Package Up to 60 Bags/Min,Low price .It usually has a high-precision sealing system that ensures that the bag is properly sealed under vacuum.If you have no special requirements for the appearance of the product packaging, then it is a good Choice for startup company.

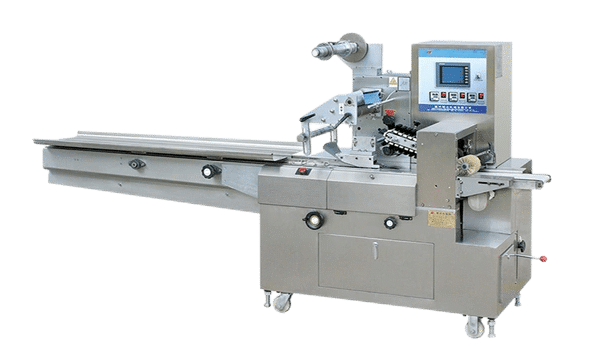

Horizontal Form Fill&Seal Packing Machine

Horizontal Form Fill & Seal Machine, also as a classic solution for vacuum packaging, is also one of the choices. Normally,we didn't suggest the model for your vaccum packaging.Package Up to 290 Bags/Min, the servo Intelligent control, run with low noise .If you have high special requirements for the accuracy of the product packaging, then it is a good Choice.

How To Find Your Idal Vacuum Packaging Machine In 4 Easy Steps

Select your market.Each industry has specific requirements when it comes to finding the most suitable vacuum or overpressure technology. By selecting your market, you will be shown all the matching lintyco products.

Select your vacuum or overpressure application.

Specifying your application allows you to target solutions that are a perfect match for your particular requirements.

Optional: Select product type, technology or product series.

Vacuum and overpressure experts who already know the product type or technology they need, can narrow the search down. You can even select a specific product series if you are familiar with the Lintyco product range.

Optional: Specify technical parameters.

You know precisely, which vacuum or overpressure level is required for your application? In this case, you can further refine the product search using specific technical parameters like pumping speed or volume flow, sometimes also referred to as flow rate.

4 Top Benifit

Reduce energy consumption

Save on maintenance costs

Lintyco offers ideal solutions for both small and large packaging machines. Right up to integrated vacuum systems that save energy costs through optimal pump performance and, with the automatic idle mode, prevent shutdowns due to maintenance.

Maximize operational reliability

Increase production output

All production teams aim for speedier processes, increased efficiency and shorter cycle times. The key is determining the best approach.

Precision vacuum technology from Lintyco helps manufacturing teams achieve their goals. Frequency controlled pumps adapt output on the fly for stable, optimized performance.

Centralized systems consolidate multiple vacuum points into a single source. This streamlines vacuum delivery while lowering energy usage through intelligent control. Lintyco can customize the perfect Integrated solution to suit specific manufacturing needs.

Application&Solution

Frequently Asked Questions

Vacuum packaging is a method of packaging where air from the interior of a package is removed in its entirety immediately prior to sealing the package. This involves placing food products in a plastic film package (or potentially a film package made with other polymer materials), removing air from inside the package with a vacuum pump, and then sealing the package (Church & Parsons, 1995)

The first step is to place the product inside the packaging material – whether a bag, rigid tray, or sealed between two foil sheets.

Next, the packaged item is positioned in a vacuum chamber or sealing station. A vacuum pump is used to evacuate the air and lower the pressure inside the chamber.

Once the targeted vacuum level is reached, the package is securely sealed to prevent air from re-entering.

For some products, a customized gas mixture replaces the air before final sealing. Known as modified atmosphere packaging (MAP), this introduces a regulated internal atmosphere tailored for the item.

Whether utilizing standard vacuum sealing or MAP techniques, automated machinery precisely controls the oxygen removal and packaging steps. This ensures a reliable process that consistently delivers the shelf life extending benefits of vacuum technology across a wide range of perishable food and other items.

Vacuum packaging greatly extends the freshness of food with no drop in quality. The suitable process depends on the item and preservation needs. Common techniques include chamber packaging, thermoforming, clipped packaging and carousel methods.

All vacuum packaging begins by placing products in some container – either bags, an upper and lower film sheet, or rigid trays. The packaging is positioned inside a vacuum chamber. Then air and oxygen are removed before final sealing takes place. This prolongs shelf life by inhibiting aerobic bacteria growth that leads to spoilage. Furthermore, taste, smell and appearance are maintained for longer. And dehydration from evaporation is minimized.

With vacuum technology, a wide array of perishable foods can be securely sealed and safely transported or stored until ready for preparation or sale. The removal of oxygen prevents chemical changes initiated by aerobic activity, keeping contents fresher for more days or weeks than conventional packing methods alone. This reduces waste in the supply chain and provides consumers with quality products that last.

Vacuum technology plays a pivotal part across diverse packaging operations. During packaging manufacturing for instance, vacuum is applied to thermoforming processes which mold plastics into specified shapes. It also features prominently in tray sealing, chamber packaging and bag filling machineries, streamlining production. Beyond these applications, vacuum pick-and-place facilitates precise component placement within automated packaging workflows. Likewise, its abilities to securely handle materials come into play for transportation handling needs. In essence, a broad spectrum of packaging applications leverage vacuum functionality every step of the way thanks to the advantages it brings for repetition, consistency and cost efficiency.

Vacuum packaging fresh foods reduces the oxygen levels in packages by around 200 times. This maintains the quality, appearance, freshness and flavor of packed products. It prevents the growth of aerobic bacteria and thus minimizes oxidation and degradation. Considerably less food is wasted as a result.

Vacuum packaging also enables attractive product presentation for customers, especially for convenience foods, at the point of sale. The packaging safely displays quality and ingredients.

For some items, a tailored gas blend replaces oxygen inside packages before final sealing. Known as modified atmosphere packaging (MAP), this specialized technique controls the internal atmosphere. MAP extends shelf life for specific product types by inhibiting factors like bacterial growth through carefully regulated gas mixtures.

Vacuum packaging is not restricted solely to solid items. Liquids like oils, sauces, remoulades and dressings can also be packaged under vacuum conditions.

However, vacuum sealing liquids presents unique challenges. To prevent leakage during the process, the bags are positioned vertically or at an angle inside the vacuum chamber. Additionally, liquids and moist products carry a risk of boiling when exposed to vacuum pressure. This potential boiling must be avoided to prevent damage to the product.

Careful bag orientation and pressure control are therefore important when vacuum packaging liquids and wet items. Proper protocol and equipment help ensure liquids remain safely contained during vacuum sealing without compromising product quality through unwanted boiling effects. With the right packaging methodology, even fluid products can benefit from oxygen removal and the preservative qualities of vacuum technology.

Vacuum packaging serves a vital purpose in medical settings where stringent hygiene standards are necessary. Medical equipment packed in a vacuum remains protected from accidental spills, splashes and other potential contamination sources.

Vacuum packaging thus helps to maintain the sterility of medical devices, surgical tools and personal protective equipment.

It also effectively shields items from other environmental factors such as humidity and can, for instance, help prevent condensation during storage.

Vacuum packaging is furthermore an efficient and space-saving means of packing. This makes it ideal for hospital use where items like bedding and clothing need to be stored in a compact way. The protective and preserving qualities of vacuum packaging ensure supplies remain hygienic and ready for use.

Vacuum forming is used to thermoform plastic cavities or pockets for blister packaging. The packaging is commonly sealed with cardboard, an aluminum foil lidding seal, or printed plastic film. This film allows product information or branding to be displayed.

Blister packaging offers the benefit of displaying a product while also preventing contact with external factors such as humidity, contamination, and tampering. If opaque blisters are used, the packaged item can be further protected against UV rays.

Blister packs are frequently employed as single-dose packaging for pharmaceuticals like tablets and capsules. They are also commonly used for small consumer goods and food items. The rigid, secure pockets help maintain product integrity during storage and shipping.

Overall, blister packaging provides both protective properties and marketing possibilities through visible product display. It represents a versatile solution for a variety of items that require tamper-proof and shelf-stable characteristics.

Vacuum packaging provides an affordable and efficient means of safeguarding goods—both in terms of hygiene and physical protection. Prior to sealing, the air and oxygen are removed from the packaging under vacuum conditions. This confers the benefit of shielding the packed items against the proliferation of aerobic bacteria, which is particularly pivotal for foodstuff packaging. Product dehydration is also greatly diminished. Owing to the restricted exposure to oxygen, vacuum-sealed foodstuffs retain their quality, flavor, smell and appearance for an extended duration, prolonging their shelf life.

When choosing a vacuum packaging machine, several factors are critical to consider:

- Cycle time: How quickly the machine can package items.

- Chamber size: The dimensions/volume the machine can handle.

- Pump-down time: How fast it can evacuate air from sealed packages.

- Operating time: The duration the machine can run continuously.

- Reliability: How dependable it is with few breakdowns.

- Warm-up time: Long does it take to get started after being turned on.

- Availability: The percentage of time it is operational.

Other operational considerations include:

- Manpower required: Number of workers needed to operate it.

- Energy/oil consumption: Running costs of the machine.

- Maintenance/overhaul costs: Expenses for upkeep and major repairs.

- Floor space: The physical footprint of the machine.

However, there is no single vacuum packaging solution that fits all applications perfectly. When designing the best solution for your needs, additional general factors should also be taken into account:

Peace of Mind: Choose a vacuum pump designed for your specific requirements that runs reliably without worries.

Extended Lifetime: Consider technology, pump configuration and proper usage to maximize the machine’s lifespan.

Saving Money with Upgrades: Processes change over time. Evaluate if upgrades could increase productivity and lower operating costs through reduced energy consumption. An expert can identify optimization opportunities.

The goal is finding a machine tailored for your unique vacuum demands both now and in the future.

Integrated vacuum supply system offers the potential to reduce operating costs and increase energy efficiency.

Our integrated vacuum systems have proven effective at optimizing packaging processes. By consolidating multiple vacuum sources into a single centralized system, industries can benefit from energy and maintenance savings.

Are you looking to evaluate how a centralized vacuum supply could help improve your operations? Lintyco has extensive experience implementing these systems. We’d be happy to discuss your requirements and recommend the best solution to maximize efficiency and reduce vacuum-related costs.