HFFS Machine

- Home

- Packaging EQUIPMENT

- Horizontal Form Fill and Seal Machine

Horizontal Form FIll and Seal Machine

LINTYCO PACK is a factory of packing machines with 10+ years experience. We have 3 kinds of horizontal form fill seal machines:

1. Pillow 4 sides seal pouch packing machine

2. Pillow back seal flowpack machine

3. Horizontal blister packing machine

Applicate for food and commodity such as candy,biscuit,cookies,sponge,trading cards, pain relief patch,hydrogel patch,blister patch, acne plaster, rapid test kit,medical products cosmetic essence, lotion, liquid oral…ect.

Automatic Horizontal Form Fill Seal Machine Choice

Depending on the product, different pouch packaging technologies are suitable for packaging foodstuffs and other products. Discover our series for the packaging industry.

Hydrogel Patch Plaster Pad Zipper Pouch Packing Machine

BG800Z is a full servo type automatica horizontal pillow type zipper pouch form fill seal packing machine. It can form zipper bag and pilow 4 sides seal bag, double use type. It can match rotary hydrogel patch plaster feeder for packing kids fever cooling patch/medical hydrogel patch. And it can match normal multi-heads feeder to feeding pain relief patch/ trading cards/eyes mask/face mask/test kit/blister patch...ect. This machine with 2 lanes, the speed can be 50-100 bag/min for zipper bag and 100-160 bag/min for normal pillow 4 sides seal pouch.

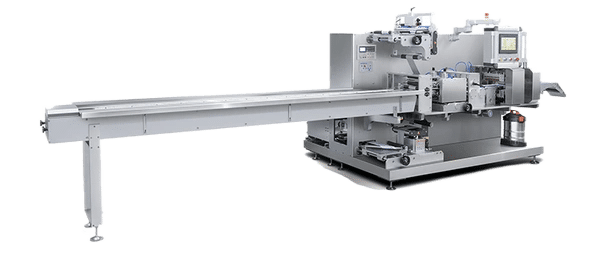

Automatic Pillow 4 sides seal flowpack machine

BG400 is full servo high speed horizontal pillow type 4 sides seal packing machine flowpack machine. It can form 4 sides seal pouch and make easy tear. It can connect multi-heads feeder to feed pain relief patch/medical plaster/trading cards/stickers/rapid test kit/face mask/eyes mask/ance plaster/hydrogel patch/blister pad...ect The speed can be 100-180 bag/min.

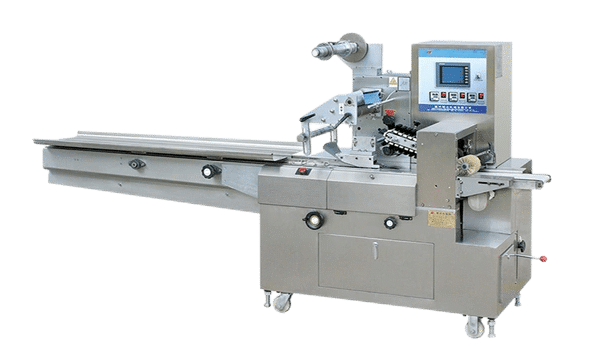

Automatic Food Commodity Flowpack Machine

Automatic food commodity flowpack machine is 3 servo flowpack machine. It has different size models such as LTC250/LTC300/LTC450...ect. It can form back sealing bag for any food like biscuit,cookies,candy,chocolate...ect and commodity like trading cards,sponge,patch,toothbrush...etc. The speed is depend on the product details and film material.

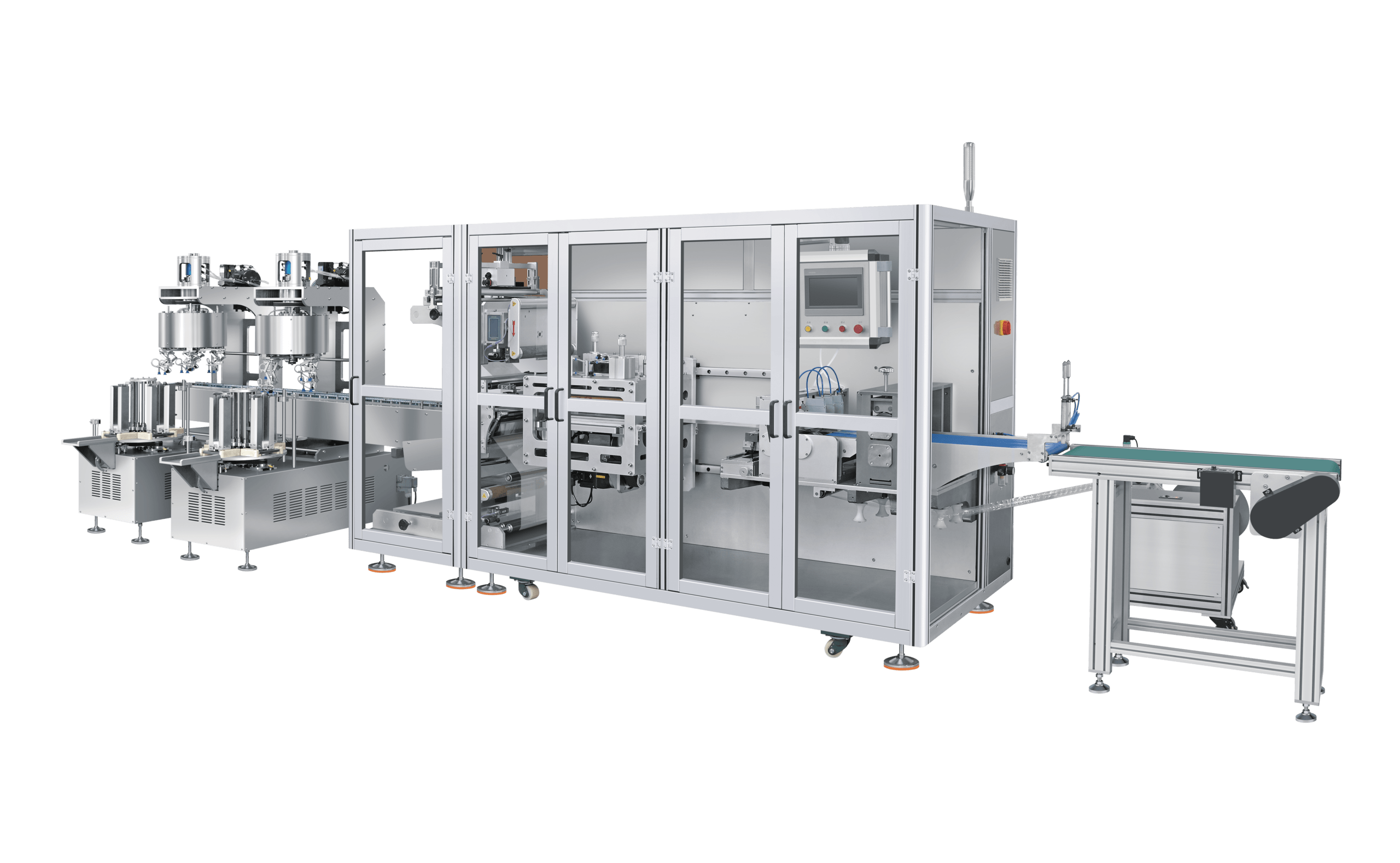

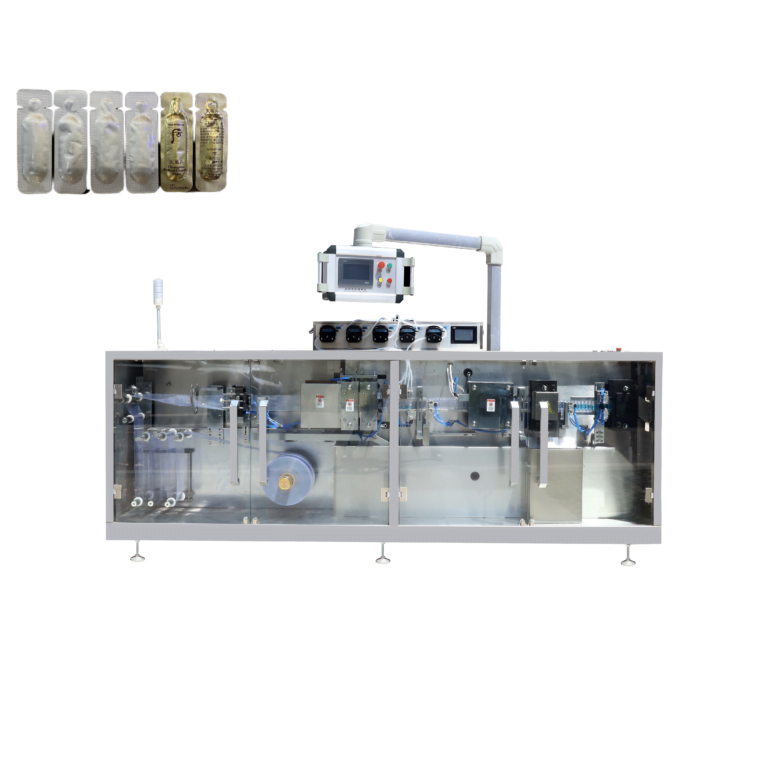

Comestic Essence Lotion Demo Form Packing Machine

This machine is horizontal double sides (ALU-ALU) aluminum blister cosmetic essence liquid demo form fill seal packing machine. It is new type double aluminum material blister model.

Flow Wrapper Machine Video

How To Find Your Idal HFFS Packing Machine In 4 Easy Steps

Evaluate Your Requirements: Begin by assessing the products you intend to package, including their dimensions, weights, and materials. Consider factors such as production volumes, packaging formats, and any specific packaging needs.

Explore Machine Capabilities: Check Lintyco HFFS machines that align with your identified requirements. Examine features like operating speeds, material compatibility, changeover times, and ease of operation and maintenance.

Prioritize Flexibility: Opt for a machine that offers adaptability to accommodate your present and prospective packaging demands. Versatile machines can expedite product changeovers and minimize downtime.

Factory tour: Before buying the horizontal form fill seal machine,you have to collaborate with reputable HFFS machine manufacturers or suppliers who possess extensive knowledge and experience in the packaging industry. Their insights can prove invaluable in selecting the most suitable solution for your specific application.At last, Factory tour is necessiary for you .

4 Top Benifit

RESOURCE-SAVING PACKAGING IN FILM AND PAPER

As the leader in hffs packaging machines, we have always put the environment first. hffs machines save up to 60 per cent more film and paper than other packaging machines, which is why we often recommend them to our customers.

Industry 4.0

Humanized programs are used to control the machine, so that one person can control it simply and reduce labor costs.

The precision of the machine is supported by the world’s outstanding partners, such as Siemens, Schneider, etc., and deep automatic machine learning, data visualization and production process monitoring are carried out so that our standard digital solutions can be suitable for every customer.

variability and integration

At lintyco, we guarantee multi-modular replacement of conveyor belts, inlet devices, sealing devices and printing devices to avoid downtime and inconvenience to our customers.

Together with the cartoning machines, our machines are often at the level of the German machines in Europe.

Extremely long service life

Our Lintyco pack machines often stay with our customers for their entire working life – 15 years is unusual, and even 30 years later, many are still in use.

Unlike ordinary commodities, machines are made to last and have a low maintenance rate, and it has always been our goal to help our customers increase their production and market share.

Application&Solution

Frequently Asked Questions

HFFS stands for Horizontal Form-Fill-Seal, which is a packaging method used to create packages by horizontally forming a film, filling it with the product, and sealing it.

The HFFS packaging system operates by horizontally unwinding a roll of packaging film. The film is then formed into a tube, and the bottom of the tube is sealed to create a bag. The bag is then filled with the desired product, such as food, pharmaceuticals, or consumer goods. Finally, the top of the bag is sealed, and the filled and sealed packages are discharged for further processing or distribution.

Foodstuffs can be packaged in pouches through various methods. Dry food items, such as snacks or cereals, are often directly filled into pre-formed pouches and sealed. For liquid or semi-liquid food products, the pouches can be filled using specialized liquid filling machines that ensure accurate and controlled dispensing. The pouches are then sealed to maintain product freshness and prevent contamination.

Vacuum is commonly used in the HFFS packaging process for certain food products. By removing air from the packaging, vacuum sealing helps to extend the shelf life of perishable food items, prevents spoilage, and maintains product quality. Vacuum sealing can be achieved by integrating a vacuum pump or system into the HFFS packaging machine.

HFFS packaging is widely used in the food industry due to its ability to provide efficient and hygienic packaging solutions. It ensures product safety, extends shelf life, and enhances the overall presentation of food products. HFFS machines can handle a variety of food packaging formats, including pouches, sachets, and trays, catering to the diverse needs of the food industry.

The main difference between horizontal form fill seal machines and vertical form fill seal machines lie in the orientation of the forming, filling, and sealing process. HFFS machines operate horizontally, forming bags or packages in a horizontal position, while VFFS machines operate vertically, forming bags or packages in a vertical position. The choice between HFFS and VFFS depends on factors such as product characteristics, production speed, and packaging requirements.

A vacuum medical devices flow wrap machine works by incorporating specialized features for packaging medical devices. These machines ensure the sterility and integrity of medical devices by creating a controlled environment, including vacuum sealing and gas flushing. The packaging process follows strict regulations and standards to meet the specific requirements of medical device packaging.

HFFS packaging offers several advantages over alternative packaging technologies. It provides efficient, high-speed packaging, reduces labor costs through automation, and allows for customization and flexibility in packaging design. HFFS machines are versatile and can handle various product types and packaging materials. They also offer excellent product protection, extended shelf life, and improved presentation.

When buying an HFFS filling system for packaging purposes, key points to consider include the desired production capacity, packaging materials compatibility, flexibility in package sizes and formats, ease of operation and maintenance, integration with other production processes, and after-sales support from the manufacturer.

An integrated HFFS packaging solution brings multiple packaging processes together into a seamless and synchronized system. It eliminates the need for separate machines or processes, optimizing efficiency and reducing production costs. An integrated system ensures smooth material flow, reduces product handling, minimizes errors, and improves overall productivity and output quality.