VFFS Machine

- Home

- Packaging EQUIPMENT

- Vertical Form Fill Machine

Vertical Form Fill Machine

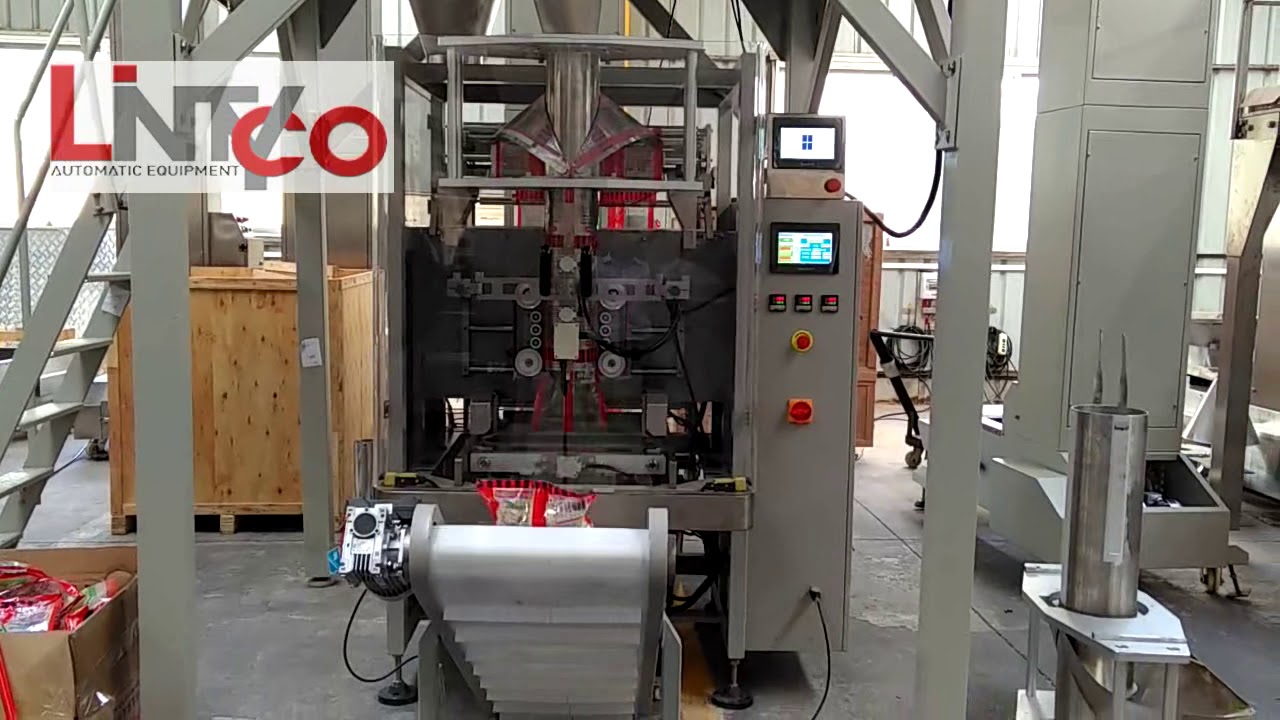

At Lintyco, we provide a comprehensive turnkey packing system that includes the LTC Vertical form, fill, and seal (VFFS) machines.We offer both OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services to accommodate your specific product requirements.

As vertical form fill seal machine manufacturer,the LTC advanced simplifies the packaging process by automatically creating bags, filling them with the product, and sealing them shut in a single operation. Its user-friendly design and compact size make it convenient and easy to use.

Automatic Vertical Form Fill Machine Choice

Depending on the product, different vffs packaging technologies are suitable for packaging foodstuffs and other products. Discover our series for the packaging industry.

- Food Industry: peanuts, popcorn, jelly, data, garlic, beans, grains, soybeans, pistachios, walnuts, rice, corn, sunflower seeds, melon seeds, coffee beans, ground coffee, potato chips, banana chips, plantain chips, chocolate ball, shrimp, sweet candy, sugar, tea, herbs, Chinese medicine, puffed food, dry food, frozen food, frozen vegetables, frozen pea, frozen fish ball, frozen pie, and other granule products.

- Pet Food Industry: dog food, bird food, cat food, fish food, poultry food and etc.

- Hardware Industry: plastic pipe elbows, nails, bolts and nuts, buckles, wire connectors, screws and other construction products.

VFFS LIQUID PACKING MACHINE

The Liquid Vertical Form Fill Seal Machine is special for liquid detergent,milk,juice ,etc.

The packing speed ranges from 5 BPM to 60 BPM.

Flexible and versatile, it can pack liquid, colloid, and slurry products. However, the products need to be low viscosity and the sealing effect is not as good as that of liquids and granules.

VFFS POWDER PACKING MACHINE

The Powder Vertical Form Fill Seal Machine has good sealing performance, the powder is not easy to fly pollution. However, the product particle size requirements are high, viscosity limit is small. Packing Speed is from 5 BPM to 60 BPM.With low price,it is first choices to pack powder.

VFFS SOLID PACKING MACHINE

Solid Vertical Form Fill Seal Machine has Strong loading capacity, suitable for large particle packaging, high processing efficiency, but not suitable for viscous or easy to drip products.

It is suitable for snack ,pet food and hardware industry.The packing speed ranges from 5 BPM to 60 BPM.

VFFS Packaging Machine Video

How To Find Your Idal VFFS Packing Machine In 4 Easy Steps

Finding the ideal VFFS packing machine for your needs can be made easy by following these four simple steps. At Lintyco, we offer an extensive range of VFFS packaging technologies that are tailored to meet specific industry and application requirements.

Step 1: Tell us your requirement

1. What product will you pack?

2. How many gram and volume in each bag?

3. What bag shape you want to get?

4. What is bag width and bag length?

5. What is bag material do you want to use?

Whether you are in the food, pharmaceutical, consumer goods, or any other sector, Lintyco has the right packaging technology for you.

Step 2: Identify your intended usage

Different applications demand purpose-built performance from VFFS machines. By identifying your intended usage, we can recommend the most suitable machine that will meet your specific requirements and deliver optimal results. Addons optional function below

1. Punching device for round hole or Euro slot.

2. Linking bag device

3. Stand bag device, for plug in at bag bottom.

4. Servo motor on horizontal sealing parts.

5. Special device if you use single layer PE film.

6. Nitrogen inflation device.

Step 3: Choose the right intergrate equipment

Experienced users may choose to filter their search by equipment varieties. If you have familiarity with certain product types, specific engineering designs, or series of VFFS machines, you can focus your search on those options. This helps streamline the selection process and ensures that you find a machine that aligns with your expertise and preferences.For example, Auxiliary equipment like metal detector,conveyor ,box packing machine,may be need to connected.

Step 4: Refine your search based on technical parameters

Get to know the precise technical parameters that are crucial to your packaging process. Refine your search by considering factors such as pumping speeds, volumes, or any other operational metrics that are important to your specific process requirements. This will help you narrow down your options and find the VFFS packing machine that perfectly matches your needs.

By following these four easy steps, you can confidently find your ideal VFFS packing machine. At Lintyco, we are dedicated to providing you with the best packaging technology that ensures efficient operations and meets your specific requirements.

4 Top Benifit

Reduce energy consumption

Drastically cut energy consumption: food manufacturers will be able to reduce energy consumption by an incredible 60% by installing a integrated vffs system from Lintyco.

In addition,VFFS machines offer high efficiency by automating the packaging process. With their advanced technology and streamlined operations, these machines can significantly increase production speed. By automating tasks such as bag forming, filling, and sealing, they reduce the need for manual labor, resulting in lower labor costs and improved overall efficiency.

Versatility and wide Range

VFFS machines are designed to handle a wide range of packaging materials, formats, and product types. Whether you need to package solid items, liquids, powders, or even irregularly shaped products, VFFS machines can adapt to meet your requirements. They offer flexibility in choosing packaging materials, including various films and laminates, allowing you to customize your packaging based on product specifications and industry standards.

Cost-effectiveness

VffS packaging solutions provide an affordable packaging solution that offers a quick return on investment. By automating the packaging process, these machines reduce the need for manual labor, thereby minimizing labor costs. Additionally, VFFS machines optimize the use of packaging materials, reducing waste and lowering material expenses. This, combined with their high production speed, translates into cost savings and improved profitability for businesses.

Reliability and easy maintence

Reliability is a crucial factor in packaging operations, and modern VFFS machines excel in this aspect. They are designed for long-lasting performance with minimal downtime. The machines undergo rigorous testing and quality control measures to ensure their reliability in demanding production environments. This reliability contributes to increased productivity and continuous operations, minimizing disruptions and maximizing output.

Application&Solution

Frequently Asked Questions

VFFS stands for Vertical Form-Fill-Seal. It is a packaging method that involves forming a bag or pouch from a roll of flexible packaging material, filling it with the desired product, and sealing it vertically. VFFS machines are commonly used in various industries for packaging a wide range of products, including food, pharmaceuticals, and consumer goods.

The VFFS packaging system typically consists of a machine with a film roll holder, a forming tube, product filling mechanism, and sealing jaws. The packaging material, usually a roll of flexible film, is unwound and passed through the forming tube, which shapes it into a bag. The bag is then filled with the product through the product filling mechanism. Finally, the sealing jaws seal the bag vertically, creating a sealed package ready for further processing or distribution.

Foodstuffs can be packaged using VFFS pouches by using appropriate VFFS machines designed for food applications. The food product is typically dispensed into the forming bag through a filling tube or auger system. The VFFS machine then forms the bag, fills it with the food product, and seals it vertically to create a secure package. This packaging method is commonly used for packaging various food items such as snacks, grains, powders, and frozen foods.

Vacuum is often used in the packaging process to remove air from within the package, creating a controlled environment. Vacuum packaging helps extend the shelf life of perishable products by reducing oxygen levels and inhibiting the growth of spoilage-causing microorganisms. It is commonly used in various industries, including food, to maintain product freshness and quality.

VFFS packaging is widely used in the food industry due to its efficiency and versatility. It is commonly employed for packaging a variety of food products, including snacks, bakery items, confectionery, grains, and more. VFFS machines can handle different types of packaging materials and offer options for customized bag sizes and shapes. This allows food manufacturers to efficiently package their products while maintaining freshness, extending shelf life, and enhancing product presentation.

A VFFS liquid packaging machine is specifically designed to handle liquid products. The machine uses a liquid filler, such as a pump or a flow meter, to accurately dispense the liquid into the formed bag. The bag is then sealed vertically to create a secure package. These machines are commonly used for packaging liquid food products, beverages, sauces, and other liquid-based items.

A VFFS medical devices packaging machine is designed to package medical devices in a controlled and sterile environment. The machine forms a bag from a roll of medical-grade packaging material, fills it with the medical devices, and seals it vertically. The sealing process ensures the integrity and sterility of the packaged medical devices until they are ready for use.

VFFS packaging offers several advantages over alternative packaging technologies. It provides high-speed packaging capabilities, allowing for efficient production and increased productivity. VFFS machines can handle a wide range of packaging materials, including various films and laminates, providing flexibility in packaging options. The vertical sealing method offers secure and aesthetically pleasing packages. Additionally, VFFS packaging is cost-effective, reduces material waste, and offers good barrier properties to protect the product from moisture, oxygen, and light.

When purchasing a VFFS system, several key points should be considered. These include the required production capacity, the type of products to be packaged (solid, liquid, or powders), the compatibility with the packaging materials, the desired bag size and format options, the ease of operation and maintenance, the level of automation and integration with other equipment, and the availability of technical support and after-sales service.

An integrated VFFS packaging solution offers several benefits. It combines various functions, such as forming, filling, and sealing, into a single system, eliminating the need for multiple machines and reducing floor space requirements. Integration ensures better synchronization and control over the packaging process, leading to higher efficiency and improved productivity. Additionally, integrated solutions often come with advanced features such as automated adjustments, quality control systems, and data monitoring capabilities, allowing for precise and consistent packaging results.