Ao considerar trabalhar com um integrador de linha de embalagem, ter uma comunicação clara é essencial para obter uma configuração bem-sucedida e eficiente. A integração da linha de embalagem envolve maquinário, processos e expertise complexos, o que torna crucial estabelecer discussões claras sobre suas necessidades e objetivos. Este artigo fornece insights sobre os tópicos mais importantes que você deve discutir com seu integrador de linha de embalagem para garantir que seu projeto corra bem. Quer você esteja interessado em automação, considerações de custo ou simplificação de operações, este guia ajudará você a tomar decisões informadas.

O que é integração de linha de embalagem e por que ela é importante?

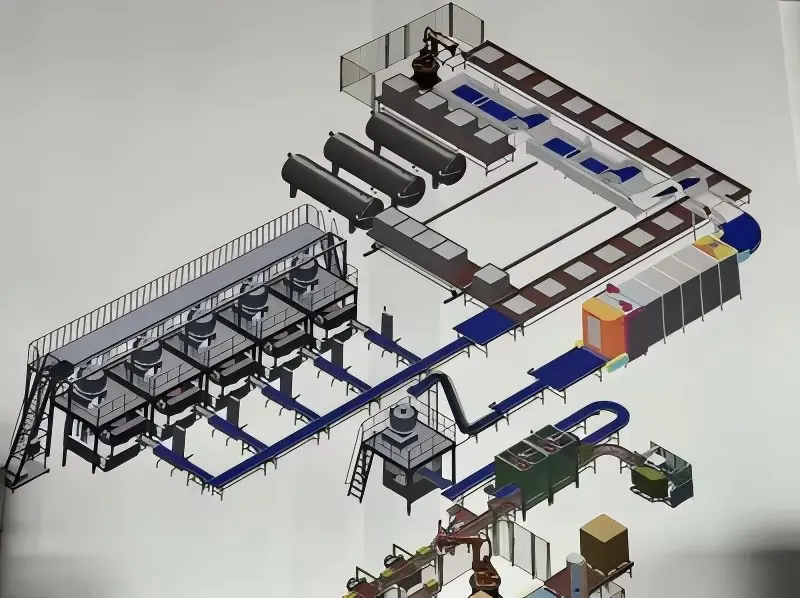

A integração da linha de embalagem se refere ao processo de coordenação e conexão de várias máquinas de embalagem em um único sistema simplificado que funciona de forma eficiente. Inclui tudo, desde máquinas de embalagem automáticas, transportadores e classificação de produtos até manuseio de materiais e embalagem final. O objetivo é criar um fluxo de trabalho eficiente que reduza os custos de mão de obra, minimize erros e aumente a velocidade de produção.

Trabalhar com um integrador profissional de linha de embalagem garante que todos os componentes da sua linha de produção sejam compatíveis, funcionem perfeitamente juntos e atendam às suas necessidades específicas. A integração adequada minimiza o tempo de inatividade, aumenta a produção e melhora a qualidade do produto, tornando-a uma parte crucial de qualquer configuração de linha de produção automatizada.

Como uma linha de embalagem automática beneficia seu negócio?

Um linha de embalagem automática oferece inúmeros benefícios, como redução de trabalho manual, aumento da velocidade de produção e garantia de maior precisão. Ao automatizar o processo de embalagem, as empresas podem eliminar o risco de erro humano, aumentar a consistência e reduzir os custos de mão de obra. A integração de sistemas automáticos também pode melhorar significativamente a qualidade do produto, pois cada item é embalado com precisão, reduzindo as chances de defeitos.

As linhas de embalagem automáticas também permitem um dimensionamento mais rápido da produção para atender às flutuações da demanda. À medida que um negócio cresce, pode ser mais desafiador manter processos de embalagem manual de alta qualidade e ritmo acelerado. Investir em uma linha de embalagem automática ajuda a mitigar esses desafios, garantindo que suas operações de embalagem possam acompanhar as necessidades de produção em expansão.

Quais fatores influenciam o custo de uma linha de embalagem automática?

O custo de uma linha de embalagem automática pode variar muito dependendo de vários fatores, incluindo o tipo de maquinário necessário, a complexidade da integração e a escala de suas operações. Algumas considerações importantes incluem:

- Tipo de máquina: Máquinas diferentes atendem a propósitos diferentes, como enchimento, selagem, etiquetagem e embalagem de caixas. Cada uma dessas máquinas pode variar em preço com base em seus recursos, capacidades de desempenho e nível de automação.

- Costumização: Quanto mais especializado o sistema, maior o custo. Recursos personalizados ou integrações que atendem ao seu produto específico podem aumentar as despesas.

- Volume de produção: Quanto maior o volume de produção, mais substancial o investimento. Linhas de alto volume normalmente exigem maquinário mais robusto e caro.

| Recurso | LTC-100L | LTC-120L | LTC150L |

|---|---|---|---|

| Velocidade | 100 unidades/hora | 120 unidades/hora | 150 unidades/hora |

| Nível de automação | Totalmente automatizado | Semi-automatizado | Totalmente automatizado |

| Custo | $200,000 | $150,000 | $250,000 |

| Requisitos de manutenção | Baixo | Médio | Alto |

| Escalabilidade | Alto | Médio | Alto |

Ao compreender esses fatores, as empresas podem planejar melhor os custos de integração de suas linhas de embalagem e tomar decisões financeiras informadas.

Como escolher o integrador de linha de embalagem certo?

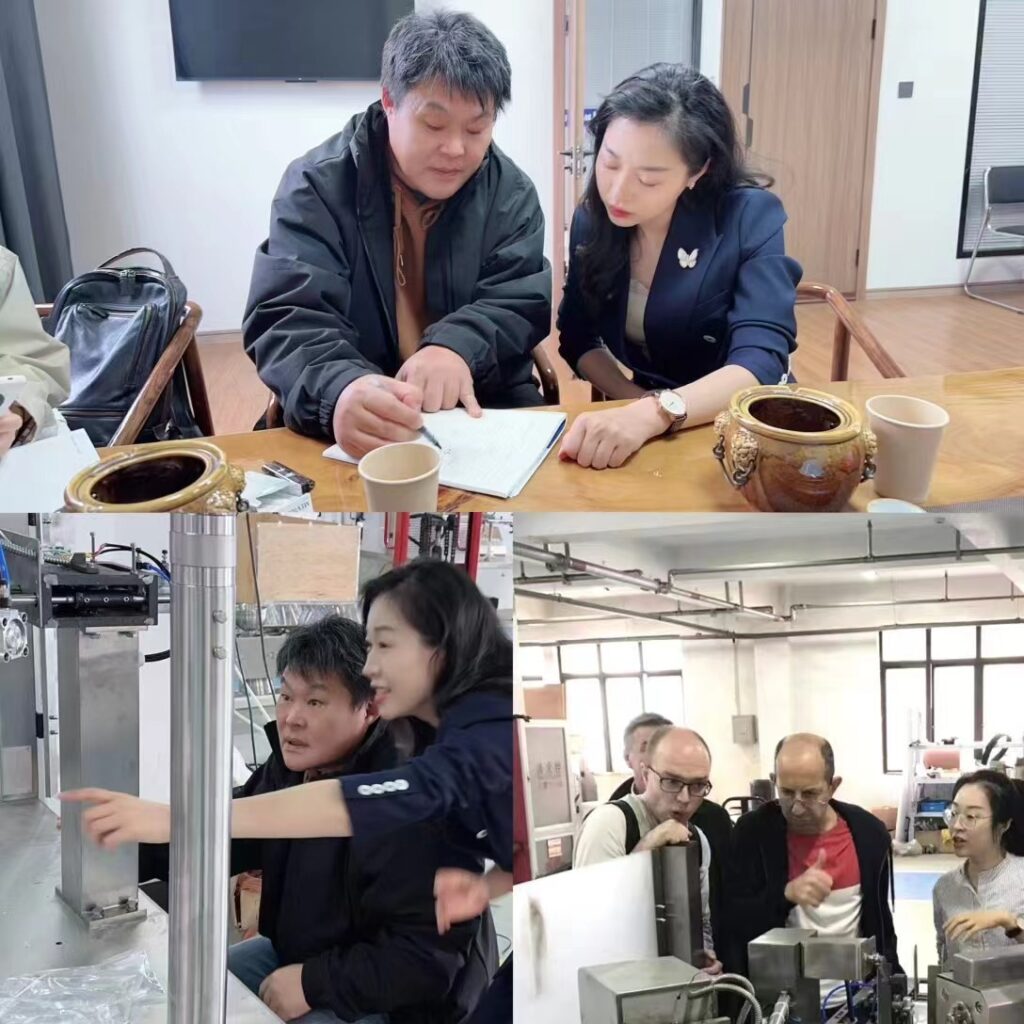

Escolher o integrador de linha de embalagem certo é essencial para garantir o sucesso do seu projeto. O integrador que você selecionar deve ter experiência em projetar e instalar sistemas de embalagem automatizados para sua indústria. Procure as seguintes qualidades em um integrador:

- Experiência: Um integrador com experiência comprovada em seu setor estará mais bem equipado para atender às suas necessidades e fornecer soluções confiáveis.

- Reputação: Analise depoimentos de clientes e projetos anteriores para avaliar a confiabilidade e a qualidade do serviço do integrador.

- Serviços de suporte: Após a instalação, você precisará de manutenção e suporte contínuos. Garanta que seu integrador ofereça suporte pós-venda robusto para resolver problemas potenciais rapidamente.

Com o integrador certo, sua linha de embalagem pode operar sem problemas, reduzindo o tempo de inatividade e garantindo eficiência operacional a longo prazo.

Quais são as principais características de uma linha de embalagem automática?

As linhas de embalagem automáticas são equipadas com vários recursos para agilizar a produção. Alguns dos recursos mais importantes incluem:

- Operação de alta velocidade: Essas linhas podem operar em velocidades muito mais altas em comparação aos processos manuais, o que aumenta a produtividade e reduz gargalos.

- Enchimento e selagem automatizados: Esse recurso garante que os produtos sejam enchidos e selados com precisão e com intervenção manual mínima, reduzindo os custos de mão de obra.

- Rastreamento de produtos: Sistemas avançados são capazes de rastrear cada produto através do processo de embalagem, proporcionando maior visibilidade e controle. Também equipado com máquina de etiquetagem automática

Esses recursos contribuem coletivamente para a eficiência e produtividade da linha, tornando as linhas de embalagem automáticas um investimento significativo para qualquer empresa que pretenda melhorar sua capacidade de produção.

Como a integração da linha de embalagem afeta a eficiência e a produtividade?

A integração adequada da linha de embalagem aumenta significativamente a eficiência e a produtividade geral. Ao automatizar tarefas repetitivas, como enchimento, etiquetagem e classificação, o sistema pode operar sem supervisão constante, aumentando o rendimento. Além disso, ao reduzir a intervenção humana, a probabilidade de erros é minimizada, resultando em menos produtos defeituosos e menos desperdício.

O processo simplificado permite que toda a linha de produção trabalhe em conjunto como uma unidade coesa, tornando os ajustes mais fáceis e rápidos. A capacidade de monitorar cada parte da linha de embalagem em tempo real ajuda a identificar gargalos, melhorando ainda mais a eficiência.

Quais desafios você deve esperar ao integrar linhas de embalagem?

Embora a integração da linha de embalagem ofereça inúmeros benefícios, há vários desafios que as empresas podem enfrentar durante o processo:

- Problemas de compatibilidade: Integrar novos equipamentos a uma linha de produção existente pode, às vezes, resultar em problemas de compatibilidade, exigindo tempo adicional ou modificações.

- Treinamento: Sua equipe precisará ser treinada nos novos sistemas automatizados, o que pode desacelerar temporariamente a produção.

- Excesso de custos:Se o escopo do projeto mudar ou surgirem problemas técnicos imprevistos, o custo da integração poderá exceder as estimativas iniciais.Baixe agora a Calculadora de ROI da Máquina de Embalagem!

Entender esses desafios e estar preparado para enfrentá-los pode ajudar a garantir um processo de integração mais tranquilo e minimizar interrupções.

Como um integrador pode ajudar na manutenção da linha de embalagem?

A manutenção é crucial para manter sua linha de embalagem automática funcionando sem problemas. Um integrador de linha de embalagem pode ajudar com isso oferecendo serviços de manutenção preventiva, solução de problemas e reparos. Eles podem ajudar você a estabelecer um cronograma de manutenção para garantir que todos os equipamentos sejam inspecionados e limpos regularmente, reduzindo a probabilidade de quebras inesperadas.

Além disso, os integradores podem fornecer treinamento para sua equipe sobre os cuidados adequados com os equipamentos e procedimentos de manutenção de rotina, ajudando-os a identificar os primeiros sinais de desgaste antes que problemas maiores surjam.

Quais tecnologias devem ser integradas à sua linha de embalagem?

A integração de tecnologias avançadas pode melhorar significativamente o desempenho e a eficiência da sua linha de embalagem. As principais tecnologias incluem:

- IoT (Internet das Coisas): Os sensores de IoT permitem que você monitore e controle sua linha de embalagem remotamente, oferecendo maior flexibilidade e rastreamento de dados em tempo real.

- Sistemas de Visão:Esses sistemas podem inspecionar produtos em busca de defeitos ou inconsistências, garantindo que apenas produtos da mais alta qualidade passem pela linha.

- Robótica: Robôs podem executar tarefas repetitivas, como classificação, embalagem e paletização, reduzindo a necessidade de trabalho manual.

Integrando essas tecnologias de Pacote Lintyco na sua linha de embalagem não só melhora o desempenho, mas também ajuda a proteger suas capacidades de produção no futuro.

Como garantir escalabilidade futura com a integração da sua linha de embalagem?

À medida que seu negócio cresce, sua linha de embalagem deve ser capaz de escalar para atender à demanda crescente. Para garantir escalabilidade futura, considere o seguinte:

- Sistemas Modulares: Os sistemas modulares permitem que você adicione novos componentes à sua linha sem grandes revisões.

- Máquinas Flexíveis: Escolha máquinas que possam lidar com diferentes produtos ou formatos de embalagem, o que permitirá que você se adapte a futuras mudanças em sua linha de produtos.

- Integrações à prova do futuro: Trabalhe com um integrador familiarizado com as últimas tendências e tecnologias, garantindo que sua linha de embalagens possa evoluir com os avanços do setor.

Ao planejar a escalabilidade, você pode evitar atualizações dispendiosas e mudanças no sistema à medida que seu negócio cresce.

Para mais informações sobre a integração da linha de embalagem e para explorar recursos adicionais, confira estes artigos: