Tea’s been a big deal around the globe since the last century, really hogging a hefty slice of the world’s consumption pie. It all kicked off with the upper crust fancying a cuppa black or green tea, and from there, tea culture started brewing up slowly but surely. The big kahunas in the tea game are Nestlé and Lipton, dishing out fresh and nifty tea blends along with some snazzy packaging. At the same time, you’ve got brands like Niche, La Fideli, and Tesis Tea, who really put the spotlight on packaging to showcase their brand mojo. Dive into this article, and you’ll get the lowdown on different types of tea, world-famous tea brands, the ins and outs of tea packaging machines, and what’s hot in the future of tea packaging trends.

Type of Tea

White Tea:

- Lightly fermented, mainly produced in Fujian,china

- Distinctive silver appearance, mild taste with cooling properties

Yellow Tea:

- Rare, slightly fermented with a mellow flavour

- Benefits include refreshing, fatigue relief, and aid to digestion

Dark Tea:

- Post-fermented, commonly pressed into compact forms

- Promotes digestion, absorption, and helps alleviate three highs

Black Tea: Fully oxidized, known for its robust flavour.

- Fully fermented, distinguished by high aroma and smooth taste

- Characterized by red color in infusion and leaf bottom

Green Tea: Minimally oxidized, offering a more delicate taste.

- Most produced type with ‘three greens’ characteristic

- Rich in chlorophyll, vitamin C, and caffeine

Oolong Tea: Partially oxidized, a balance between black and green teas.

- Semi-fermented, known for complex process and unique aroma

- Combines the freshness of green tea and the richness of black tea

Herbal Tea: Made from herbs, fruits, seeds, or roots, caffeine-free.

Suggestion: Green tea for summer, Black tea for winter,White tea for spring .

Types of Tea Packaging

Tea Bags: Tea bags are typically made of a filter bag, cotton string, and a tag. Due to their convenience, this is a commonly used method for individual packaging.

Loose Leaf: Requires ample space, usually packaged in cans and stand-up pouches. Stand-up pouches allow for custom design, meeting packaging needs while enhancing aesthetic appeal. Generally, nitrogen is flushed into stand-up pouches during packaging to ensure long-term preservation.

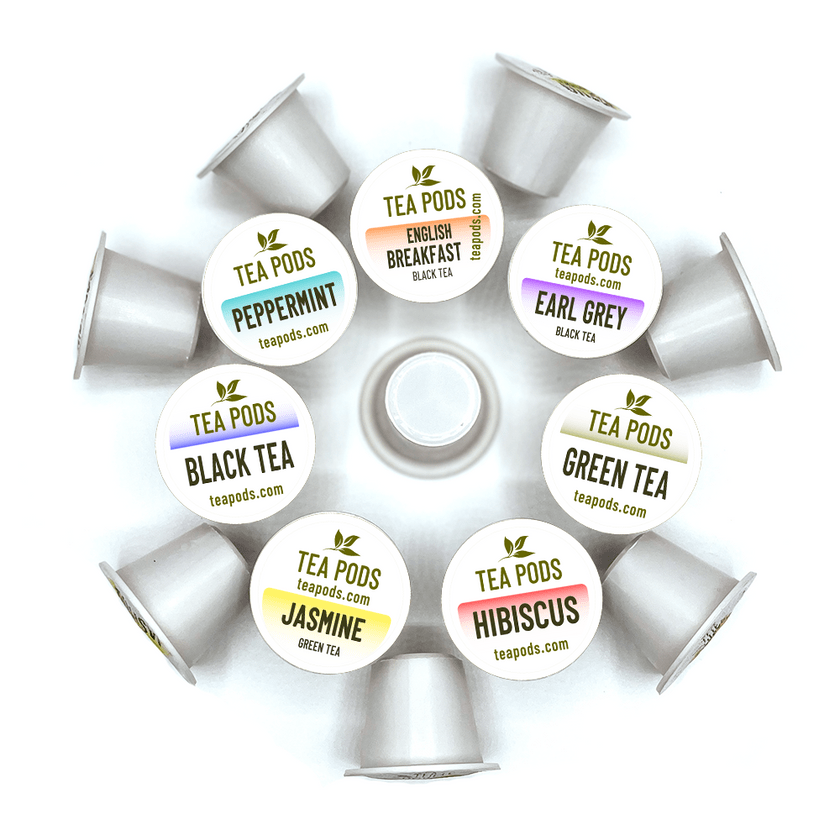

Tea Pods: The latest in packaging methods, generally requiring customized packaging machines. Suitable for medium to large enterprises.

How to Package Tea for Sale

Automatic Tea Bag Machines: The most commonly used machines by Lipton and other brands. Equipped with tags and strings, they are divided into horizontal and triangular bags. These machines are suitable for small packaging of tea.

Loose Leaf Tea Packaging Machines: Specifically designed for stand-up pouches. They offer large space, fully automated operations, and flexible packaging. The packaging process typically includes a weighing system, filling system, and sealing system.

Pod Packaging Machines: Specialized for creating tea pods for single-serve machines.

Choosing the Right Tea Packing Machine

- Understand Your Product:** Determine the packaging style you want, whether it’s small-capacity triangular bags, stand-up pouches, barrels, or tea pods.

- Production Capacity: Speed requirements are crucial for every tea producer. The minimum speed requirement should be higher than manual processing.

- Quality and Reliability: The quality of a machine is not just about the hardware; the software is also very important. Software determines the smoothness of the packaging process.

- Budget: Balance between affordability and the features you need.Download Machine ROI Here

- After-Sales Service: Easy replacement of parts and convenient maintenance are vital for tea factories, as a day of downtime can cause significant inconvenience.

FAQ

1.How Do Different Types of Tea Packaging Machines Work?

Answer: Various types of tea packaging machines include automatic tea bag machines, loose leaf tea packaging machines, and tea pouch filling machines. Each type offers different functionalities, like weighing, bagging, sealing, and labeling, to cater to specific packaging needs.

2.How Can Businesses Choose the Right Tea Packaging Machine?

Answer: When choosing a tea packaging machine, businesses should consider factors such as the type of tea being packaged, the required production capacity, the variety of packaging formats needed, and the machine’s flexibility and ease of maintenance.

3.What Are the Benefits of Using Automated Tea Packaging Machines?

Answer: Automated tea packaging machines offer benefits like increased production speed, consistency in packaging, reduction in labor costs, and enhanced precision in filling and sealing, which contributes to maintaining the quality of tea.

Automatic tea packing machine from Lintyco

Selecting the right tea packaging machine is vital for maintaining the quality of your tea and efficiency in production. Consider the type of tea, packaging style, and your production needs to make an informed decision. Investing in the right machine can significantly impact your tea business’s success.

Lintyco is a pioneer and leader in automated tea and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.