การแนะนำ

What exactly is a 3 Side Seal Pouch? Why are so many companies opting for it?

Manufacturers and businesses looking for reliable, cost-effective packaging often turn to these pouches for their ability to protect contents and enhance brand presentation. One solution that has consistently stood out for its versatility and efficiency is the ซองซีล 3 ด้าน.

In this article, we’ll dive into the details of 3 Side Seal Pouch Packaging Machines, the benefits they offer, and how to choose the right one for your production needs.

What Is 3 Side Seal Pouch?

ก ซองซีล 3 ด้าน is a type of flexible packaging that is sealed on three sides, leaving the fourth side open for filling. These pouches are typically made from high-quality films, providing excellent protection against moisture, oxygen, and light. The three seals—two on the sides and one on the bottom—create an airtight, tamper-evident seal that helps extend shelf life and preserve the freshness of the product inside.

The design of a 3 side seal pouch offers several advantages: it maximizes available space for branding and product information, simplifies manufacturing, and provides a cost-effective solution for packaging small quantities of products. This type of pouch is commonly used in a variety of industries, including food, pharmaceuticals, cosmetics, and chemicals.

You can check them below.

- Food and Beverages: It is ideal for packaging snacks, powders, condiments, and liquid-based products. They ensure freshness and help extend the shelf life of perishable goods.

- ยา: 3 side seal pouches are used for packaging medicines, vitamins, and supplements, providing airtight seals that preserve product integrity.

- Cosmetics and Personal Care: 3 side seal pouches are commonly used for packaging products like shampoos, lotions, and creams, as they offer a sleek and attractive presentation.

- เคมีภัณฑ์: For industrial chemicals, fertilizers, and cleaning agents, 3 side seal pouches provide a safe and reliable packaging option that resists contamination.

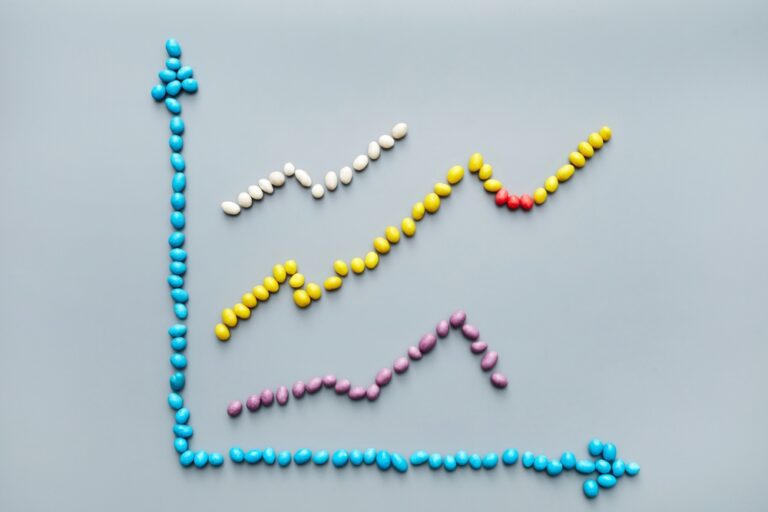

Why Most Brand Manufacturers Choose 3 Side Seal Pouch?

Are you going to set up a new brand or factory?

The quickest and cheapest way is to refer to the answer other ones given to you.

Most Brand manufacturers increasingly prefer 3 Side Seal Pouches for several compelling reasons:

- Cost-Effectiveness: 3 side seal pouches are often more affordable compared to other types of packaging. They require less material and fewer processing steps, which lowers production costs.

- Space Efficiency: The minimalistic design of 3 side seal pouches allows for more space to be dedicated to branding and product information. This is especially important in industries where packaging plays a key role in attracting customers.

- การปกป้องผลิตภัณฑ์ที่ได้รับการปรับปรุง: With excellent barrier properties, 3 side seal pouches provide strong protection against environmental factors like moisture, air, and UV light, ensuring the product inside remains fresh for longer periods.

- ความเก่งกาจ: These pouches can be used for a wide range of products, including powders, granules, liquids, and solid items. This versatility makes them ideal for many different industries.

- สะดวกในการใช้: The packaging process is simple and efficient. The open-ended design allows for easy filling, while the three seals ensure the contents are securely enclosed.

How Many Types of 3 Side Seal Packaging Machines?

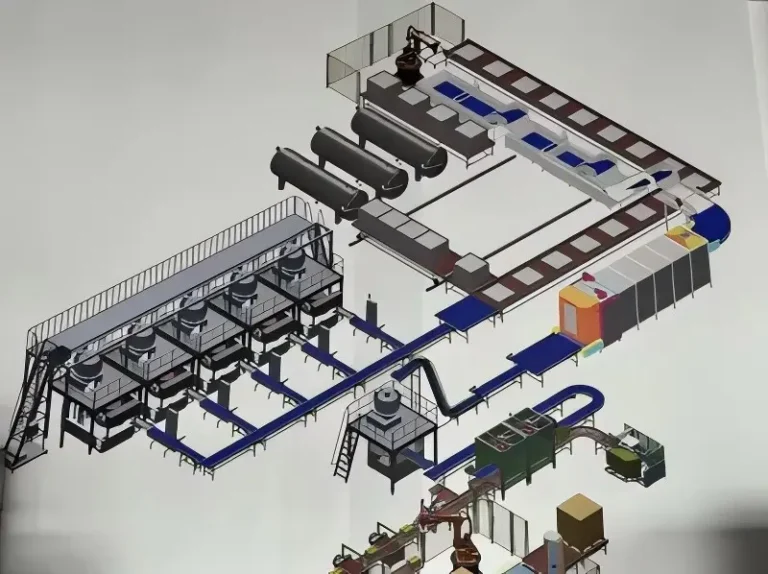

There are several types of 3 Side Seal Packaging Machines, each designed to cater to specific production needs. These machines can be classified into two main categories:

Manual 3 Side Seal Machines: These machines are ideal for low-volume operations. The process typically involves filling the pouch manually before sealing it on three sides using heat or ultrasonic sealing technology.

Automatic 3 Side Seal Machines: Automated machines are designed for high-volume production. These machines fill, seal, and sometimes even label the pouches in one continuous process, improving efficiency and reducing human error.

Types of Automatic 3 Side Seal Pouch Machines include:

เครื่องซีลปากถุงแนวตั้ง (VFFS): These machines form the pouch from a roll of film, fill it with the product, and seal it on three sides.

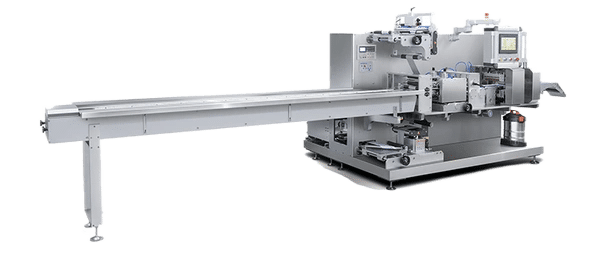

เครื่องกรอกแบบฟอร์มแนวนอน (HFFS): Hffs machines use pre-made pouches, fill them with the product, and then seal the pouches.

The Benefits of Automatic Packing Machine

What are the advantages of automatic packaging machine over a manual packaging machine?

Automatic packing machines, particularly those used for 3 Side Seal pouches, offer numerous advantages that are critical for efficient and scalable packaging processes:

เพิ่มผลผลิต: Automation reduces the need for manual labor and speeds up the packing process, allowing manufacturers to handle large volumes of products in less time.

ความสม่ำเสมอและการควบคุมคุณภาพ: With automated systems, the sealing and filling process is more precise, ensuring each pouch is sealed perfectly and the right amount of product is used every time.

ประหยัดต้นทุนแรงงาน: By minimizing the need for manual intervention, companies can reduce labor costs and redirect resources to other areas of production.

Flexible Packaging Options: Automated machines can handle a variety of pouch sizes and materials, making them versatile for different product types and industries.

Reduced Risk of Contamination: Automation lowers the risk of human errors or contamination during the packaging process, ensuring a higher level of hygiene and safety.

How To Choose The Automatic Packing Machine?

When selecting an automatic 3 side seal pouch packaging machine, there are several key factors to consider:

Production Speed: Choose a machine that matches your production capacity needs. Faster machines are suitable for high-volume operations, while slower machines might be better for smaller batches.

Pouch Size Compatibility: Ensure the machine can accommodate the pouch sizes and materials you require. Some machines can handle a variety of sizes, while others may be limited to specific dimensions.

สะดวกในการใช้: Look for a machine that is user-friendly, with easy setup and maintenance procedures. Intuitive controls can help minimize downtime and training time.

Sealing Technology: The type of sealing technology used (e.g., heat sealing, ultrasonic sealing) will impact the strength of the pouch seal and the overall quality of the packaging.

Cost vs. Return on Investment (ROI): Consider the long-term ROI. While automatic machines may have higher initial costs, they can offer greater efficiency and lower operating costs in the long run.

Frequently Asked Questions About 3 Side Seal Pouch Machines

1. What materials can a 3 side seal pouch packing machine handle?

These machines work with various flexible films, including polyethylene, polypropylene, laminated films, and multi-layered materials. The specific material choice depends on your product’s packaging needs and required protection level.

2. Can 3 side seal pouches be used for both food and non-food items?

Yes! These machines are versatile enough to package both food products (like snacks, coffee, and pet food) and non-food items (such as cosmetics, pharmaceuticals, and medical supplies). The reliable sealing technology keeps all contents safe and secure.

3. Are these machines customizable?

Absolutely. Manufacturers offer various customization options to match your production needs, including different pouch sizes, sealing methods, and integrated features like automatic filling systems, labeling, and date printing.

4. What are the maintenance requirements for a 3 side seal pouch machine?

Though designed for minimal maintenance, these machines need regular cleaning, lubrication, and inspection to run smoothly. The sealing mechanisms occasionally require adjustment for optimal performance.

5. How does the machine ensure product safety?

The three-side seal creates an airtight, tamper-evident closure that prevents contamination and maintains product freshness. This secure sealing system ensures contents stay safe until use.

สรุป

3 Side Seal Pouch Packaging Machines are essential for businesses looking to streamline their packaging process while maintaining high-quality standards. These machines offer cost savings, flexibility, and improved product protection, making them a popular choice across various industries. Whether you are just starting out or looking to upgrade your packaging process, choosing the right machine is crucial to achieving long-term success. Keep the factors mentioned in mind when selecting your equipment to ensure you meet your production goals efficiently.