In the ever-evolving world of food production, efficiency and safety are paramount. As an important part of the food manufacturing process, packaging plays a key role in protecting products, branding items for retailers, and providing informative labels for consumers. Horizontal flow food packaging machines offer an automated solution that delivers numerous production and operational benefits compared to manual packaging methods. In this comprehensive guide, we’ll delve into the intricacies of HFFPMs, their benefits, and why they’re becoming an essential part of modern food production lines.

What is a Horizontal Flow Food Packaging Machine?

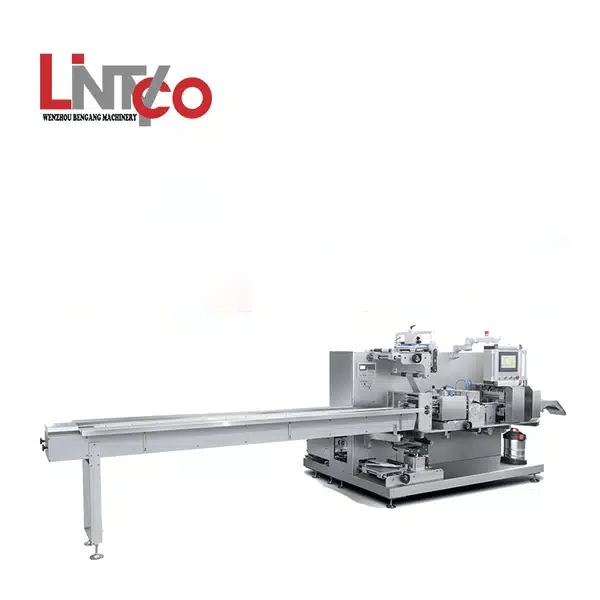

The Horizontal Flow Food Packaging Machine, also known as flow wrap machine, is a device that packages products in a secure, efficient, and cost-effective manner. Unlike vertical packaging machines that operate in an up-and-down motion, HFFPMs work horizontally. They use a single film coil situated at the machine’s base to package products ranging from baked goods and snacks to meat and dairy products.

How Does a Horizontal Flow Food Packaging Machine Work?

The HFFPM process begins as the product is placed on a conveyor belt. The machine then folds the film around the product, creating a tube. The edges of this tube are sealed longitudinally, and then the ends are sealed, creating a package. This method ensures a secure and hygienic seal, protecting the food from external contaminants.

Here are the specific steps in how a horizontal flow packaging machine works:

- Products are loaded onto the infeed conveyor in single layers.

- As products move through, rollstock film is unwound from its roll.

- Sealing tools heat seal the film edges, wrapping the leading film completely around the products.

- A transverse seal cuts and heat seals the film vertically between each product.

- The products continue along the conveyor while the film isalso fed forward in a continuous wrap.

- A second transverse seal cuts the wrapped package from the film tube.

- Finished packages are discharged via the outfeed conveyor for storage or shipping.

- The machine repeats this process non-stop to maximize output rates.

The Benefits of Using Horizontal Flow Food Packaging Machines

Increased Output Capacity

The continuous, high-speed nature of horizontal flow machines allows for packaging throughput rates that manual methods simply cannot match. Industries requiring large volume outputs can maximize line efficiencies.

Consistency

Precise packaging is ensured batch after batch due to the machine’s automatic and regulated functions. This consistent packaging quality helps reduce product damage or tampering.

Reduced Labor Costs

The machine minimizes labor needs since packaging tasks are automated. Fewer employees are required to operate the line compared to manual packaging workflows.

Packaging Flexibility

These machines can accommodate different product sizes and formats on a single line. Changeover to new SKUs is also faster than reconfiguring manual packing stations.

Improve Food Safety

Automatic in-line packaging in a controlled environment reduces human contact and contamination risks compared to manual packaging. It also forms air-tight protective seals.

Branding Opportunities

Packs can be custom printed, labeled, or marked on demand to differentiate products for clients and end users with minimal changeover times.

Lower Operating Costs

Over time, horizontal flow packaging machines deliver a lower total cost of ownership through higher throughput, labor savings, reducing waste, and consistent operational efficiencies compared to manual packaging alternatives.

By offering these advantages, horizontal flow machines provide an optimal packaging solution for many industries’ high-volume production needs. Their automation drives efficiencies while delivering high-quality, safe packaging run after run.

The Role of HFFPMs in the Future of Food Production

The future of food production leans towards automation, and HFFPMs are at the forefront of this movement. Their ability to adapt to different products, coupled with their speed and efficiency, makes them an ideal choice for businesses seeking to optimize their packaging processes.

Moreover, with increasing consumer awareness about food safety and hygiene, the demand for machines that can guarantee secure, contaminant-free packaging is also growing. HFFPMs meet this demand, making them an integral part of the future food production landscape

FAQ

Q: What are Horizontal Flow Food Packaging Machines (HFFPM)?

A: Horizontal Flow Food Packaging Machines (HFFPMs) are automated packaging systems used for wrapping food products. Unlike vertical packaging machines, they operate horizontally and are particularly effective for packing products like baked goods, snacks, meats, and dairy products.

Q: What products are best suited for HFFPMs?

A: HFFPMs are versatile and can be used for a wide range of food products, including baked goods, snacks, confectionery, meats, cheeses, and dairy products.

Q: How do HFFPMs contribute to food safety?

A: HFFPMs contribute to food safety by reducing human contact during packaging, thus minimizing contamination risks. They also create air-tight seals that protect food from external contaminants.

Conclusion

From their operational mechanics to their numerous benefits, Horizontal Flow Food Packaging Machines are transforming food production. They offer a versatile, efficient, and safe solution to packaging needs, making them an invaluable asset for any food processing and packaging business. As we move towards a future dominated by automation and heightened food safety standards, the importance of HFFPMs will only continue to grow.

Remember to stay informed and adapt to advancements in technology – the future of food production is here, and it’s moving at an unprecedented pace. With the help of machines like the HFFPM, we can look forward to a safer, more efficient, and more sustainable food industry.