In recent years, food hygiene and safety accidents have occurred frequently, and people’s requirements for food hygiene also continue to improve. For food and cosmetic businesses, improving production to enhance the hygienic quality of the product is of utmost importance, as the hygienic quality of the product is particularly important. Filling is a key link in the liquid packaging, automatic filling machines in this connection play a very important role. This article introduces a variety of different forms of liquid filling machine principles of operation and basic features of this article introduces a variety of different forms of liquid filling machine principles of operation and basic features, as well as the scope of application, and describes the choice of filling machines needed to consider several key points.

Introduce

The use of filling machines can lead to high-volume production of food, pharmaceuticals, and household chemical enterprises, and then help manufacturers achieve their goal of high-speed production. In the past, filling machines were not the first choice for companies in the food, pharmaceutical, and cosmetic industries. The development of filling machines was not perfect and had numerous shortcomings, including high procurement costs, large and heavy equipment, installation difficulties, maintenance costs, and other issues. However, now that advanced technology and new filling systems have replaced the shortcomings of filling machines, more and more companies are starting to pay attention to and use filling machines, and they are starting to realize the benefits they can bring to them. Filling machines in the food, medicine, and cosmetics production enterprises play an important role in the selection and use of the right filling machine, directly related to the quality of the product and the efficiency of production, so it has become a major production enterprise have to pay attention to the topic.

Type of Food Filling Machine

Filling equipment is a small type of packaging equipment, is the food, drugs, daily necessities and other products automatically filled into the container, and automatically achieve the quantitative equipment; from the point of view of the packaging of materials can be divided into liquid filling machine, paste filling machine, powder filling machine, granule filling machine, containing particles of sauce filling machine, etc., this article focuses on the food and beverage industry to use the most widely used in the principle of the various characteristics of the liquid filling machine and scope of application.

Atmospheric pressure liquid filling machine

The machine operates under both liquid self-weight filling and atmospheric pressure conditions, relying on liquid self-weight filling. This type of filling machine is divided into two types of timing filling and fixed capacity filling, only for filling low-viscosity liquids that do not contain gas, such as milk, wine, drinking water, etc. The benefits of this filling machine include its simple structural principles, low equipment cost, and simple maintenance. However, the machine for quantitative filling is rougher. For high-value-added products, filling loss is larger, and this type of machine is more widely used in the drinking water industry in more applications.

Pressure filling machine

The machine is in the filling machine. The cylinder pressure is higher than atmospheric pressure for filling, and can be divided into two types: one is the pressure in the reservoir cylinder and the bottle pressure is equal, relying on the self-weight of the liquid in the bottle and filling, referred to as isobaric pressure filling; the other is the pressure in the reservoir cylinder is higher than the pressure of the bottle, the liquid flows into the bottle by the pressure difference, using a high-speed production line. A pressure-filling machine is suitable for filling liquids containing gas, such as beer, soft drinks, champagne, etc.

Vacuum filling machine

The machine is in the bottle pressure and filling cylinder pressure below atmospheric pressure for filling. This filling machine structure is simple and highly efficient, and the viscosity of the material adapts to a wide range, such as oils, syrups, fruit wines, soy sauce, vinegar, and fruit juice drinks, etc. can be applied. Different vacuum degrees can be designed according to the viscosity size of the filling liquid to achieve the required filling speed. At the same time, the filling process can be late through the filling valve on the vacuum pipe will be excess liquid pumped back into the cylinder, to achieve precise positioning; according to the technical level of different equipment manufacturing units at home and abroad, the filling level line deviation can be controlled at 1-3mm, so that the level of the product level after filling line looks consistent, conducive to the image of the product on the shelf;

Flow meter filling machine

The machine refers to the installation of a high-precision electronic flow meter in each filling valve’s pipeline, through which the liquid volume is measured to achieve quantitative filling. The advantage of this approach is the simple structure of the equipment. Without the need to configure the equipment buffer cylinder, the filling valve design is simple, simple, and thorough automatic cleaning, and the filling process, the filling valve will not come into contact with the mouth of the bottle, clean and hygienic, without the risk of cross-pollution. For adjusting the filling volume, you only need to modify the parameters that can be adjusted without the need to replace any parts, This filling method is widely used both at home and abroad because it significantly improves traditional filling methods’ accuracy. However, due to the limitations of the flow meter itself, this type of filling machine can’t handle materials without conductivity or containing gas. Non-conductive liquids can not be measured by the flow meter, such as cooking oil, and materials containing gas result in measurement errors, making it difficult to use the flowmeter filling machine for filling;

Weighing filling machine

Type filling machine refers to installing a high-precision dynamic electronic scale at each filling station, and quantitative filling is achieved by measuring the weight on the electronic scale. This filling method has all the advantages of a flowmeter filling machine, and the versatility of application is broad, not just to adapt to different viscosities of the material but also for the liquid containing air bubbles, such as milk, soy sauce, dairy drinks, etc.; In addition, the filling accuracy of this filling method is far more than any other filling method, for the 2kg of products, the filling accuracy can be up to 2 grams, which is not comparable to other filling methods. This is not comparable to other filling methods. Currently, this filling method is being widely used by some high-value-added products enterprises; and domestic and foreign packaging equipment manufacturing enterprises. However, due to the high technical requirements of the equipment, the cost of components is expensive, resulting in equipment costs being higher than other forms of filling machines, for some small-scale enterprises, there are certain difficulties in equipment investment.

Working Process of Food Filling Equipment

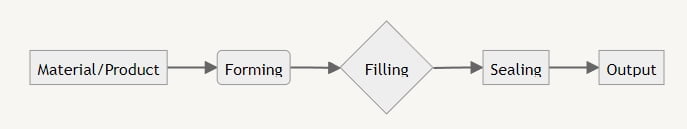

Bag Filling Machine

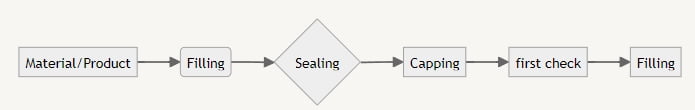

Bottle Filling Machine

Maintenance and Troubleshooting

Many producers neglect maintenance and troubleshooting. Stable use of the machine determines the output of product yield. Once maintenance is done it may take several tonnes less output to be produced.

How to maintain food filling machines on a daily basis

(1) Before using the filling machine, you should first check if the power supply is normal, the material supply pipeline is normal, and if the valve is opened correctly.

(2) In the checks mentioned above, the parameters are correct and the appropriate methods for changing the filling weight are the mouth and cap searches. Confirmation: After resetting the emergency stop button, press the start button to start filling.

(3) After filling, the material should be weighed to verify its weight. If the weight is incorrect, adjust the filling weight of the filling machine. Click on the ” Parameter Setting in the Change” and change the filling weight to a reasonable value. After completing the filling, exit the interface to the filling display interface, fill again, and verify the weight until there are no errors.

(4) If the mouth-searching method is not correct when checking, change it in the “Parameter Setting.

Note: When changing the parameter, it is not allowed to fill it; it should continue to fill after changing the parameter.

Troubleshoot

| NO | Failure phenomenon | Possible causes | Treatment |

|---|---|---|---|

| 1 | No power indication or indication but no action | No power or phase loss | Check whether the incoming power supply and all kinds of power supply in the box are suitable. |

| Fuse is blown | Replace the same specification fuse core | ||

| 2 | Cylinder does not operate or operates abnormally | Solenoid valve short-circuit caused by water | Use a dry cloth to wipe out water stains, tighten the solenoid valve terminal screws, ensure that the solenoid valve terminal dry. |

| Solenoid valve without 24V voltage | Check the state of the line, first check the corresponding box in the action to the position when there is no 24V power, if so, check the external line. | ||

| Dirt in the valve spool of the air circuit board | Clean the valve spool with clean gasoline, exclude foreign objects, such as damage to the need to replace the solenoid valve valve parts. | ||

| Throttle improperly adjusted | Adjust the throttle position when the clockwise rotation, the cylinder speed up; when the counterclockwise rotation, the cylinder speed slows down. | ||

| 3 | Pump stops suddenly and alarm sounds. | Thermal relays operate due to overload or phase failure. | Check the power supply status and check the pump’s condition, there is no jamming, gambling and make maintenance accordingly. |

| 4 | Sudden stoppage of the drive chain, misalignment occurs | Sudden stop during travelling causes misalignment. | Push out the spindle cylinder in manual mode and push the chain to restore the working position to normal. |

How to Choose Right Filling Machine

The best choice for filling machines is to maintain product quality and increase economic efficiency. In general, should be closely linked to actual production, and try to choose high quality, high efficiency, simple structure, easy to use, and maintain, widely applicable filling machines. When choosing a filling machine, it’s important to follow the principles of choice.

The principle of serving the production process. Firstly, based on the nature of the filling material (viscosity, foaming, volatility, gas content, etc.), choose the appropriate filling machine to meet the production process requirements. For example, for more aromatic liquor, it is recommended to use cup-type or atmospheric pressure filling machines to prevent the loss of volatile aromatic substances. For fruit juice, it is recommended to use vacuum filling machines to maintain product quality. Secondly, the filling machine’s production capacity and the processing and packaging machinery to match it.

The principle of high productivity and high product quality. The productivity level directly reflects the production capacity of the production line. The higher productivity leads to better economic benefits. To enhance product quality, we should choose equipment with high precision and high levels of automation for filling machines. However, the cost of the equipment is also correspondingly higher, increasing the unit cost of the product. Therefore, the selection of a filling machine should be combined with the requirements of the production process and relevant factors for comprehensive consideration. Products such as high-value-added ones should be preferred over machines such as flowmeters or weighing filling machines for high-precision filling. If the added value of a product is low, such as ordinary drinking water, it should be preferred over low-cost, ordinary drinking water filling machines.

The principle of a wide process range. The filling machine’s process range refers to its ability to adapt to different production needs. The wider the process range, the more efficiently the equipment can be utilized, leading to a multi-purpose machine that can be used with a variety of materials and specifications. To meet the needs of the liquor, beverage industry, multi-species, and multi-specification production industry, it’s best to choose the widest possible range of filling machine processes. A flowmeter and filling machine for non-bottle mouth contact filling, bottle size and filling capacity to accommodate a wider range and be suitable for filling various media.

FAQ

1.What Are the Main Types of Food Filling Machines?

Answer: The primary types of food filling machines include atmospheric pressure liquid filling machines, pressure filling machines, vacuum filling machines, flow meter filling machines, and weighing filling machines. Each type is designed to handle different types of food products and offers unique advantages in terms of efficiency, precision, and suitability for specific applications.

2.What Factors Should Be Considered When Selecting a Food Filling Machine?

Answer: Key considerations include the type of product being filled (liquid, paste, powder, granule), the machine’s capacity and speed, the level of automation required, compatibility with various packaging types, and the machine’s precision and accuracy.

3.How Do Different Food Filling Machines Ensure Product Freshness and Safety?

Answer: These machines ensure product freshness and safety through efficient sealing capabilities, maintaining hygiene standards, and preventing contamination during the filling process.

4.What Support Does Lintyco Packaging Offer for Food Filling Machine Solutions?

Answer: Lintyco Packaging provides comprehensive support including expert consultancy on machine selection, installation, training on operation and maintenance, and ongoing technical support to ensure optimal performance and longevity of the machines.

Automatic Filling Solution From Lintyco

Lintyco is a leader in automated filling machines and end-to-end packaging systems. Lintyco’s innovative filling solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.