Introduction

Several options exist in the manufacturing industry to ensure food is packaged safely and delivered to the customer without being tampered with. Here we have broken down the different kinds of industrial food packaging machines and their many uses to help businesses differentiate with exactly what they need.

Reading this article will help you who are looking for a food packaging machine to choose the right machine.

Market Outlook: Food and Packaging Machine for Food Products

The global food market is expected to reach US$ 195.9 billion in 2024 and US$ 391.1 billion by 2034. By 2034, the market is projected to rise at a 9.2% CAGR.

With the increasing demand for RTE foods, a wide range of RTE products are available in the market, including instant breakfast & cereals, bakery & confectionery products, and meat products. Further, ready-to-eat vegetables and salads are becoming highly popular in emerging countries due to the convenience of consumption, good taste, and growing awareness of the health benefits of vegetables.

FutureMaketSights shows the estimated growth rates of the top four countries. The United States, India, and China are set to record high CAGRs of 6.5%, 6.9%, and 7.3%, respectively, through 2034.

| Countries | CAGR |

|---|---|

| United States | 6.5% |

| Germany | 5.3% |

| India | 6.9% |

| China | 7.3% |

So packaging machine for food product is more popular than ever.According to the “China Food Packaging Machine Market Analysis and Feasibility Study Report 2024-2028” published by Xinxin Industry Research Centre, China’s food packaging machine industry has shown steady growth in recent years, with the market size growing from more than 10 billion yuan in 2019 to approximately 43 billion yuan in 2024.The market size is expected to grow to 115.85 billion yuan in 2028. This growth trend is attributed to a number of factors, including technological advancements, expanding market demand, and changes in the competitive landscape within the industry.In particular, the development of automation and intelligent technologies has led to the continuous improvement of the performance and efficiency of food packaging machines.

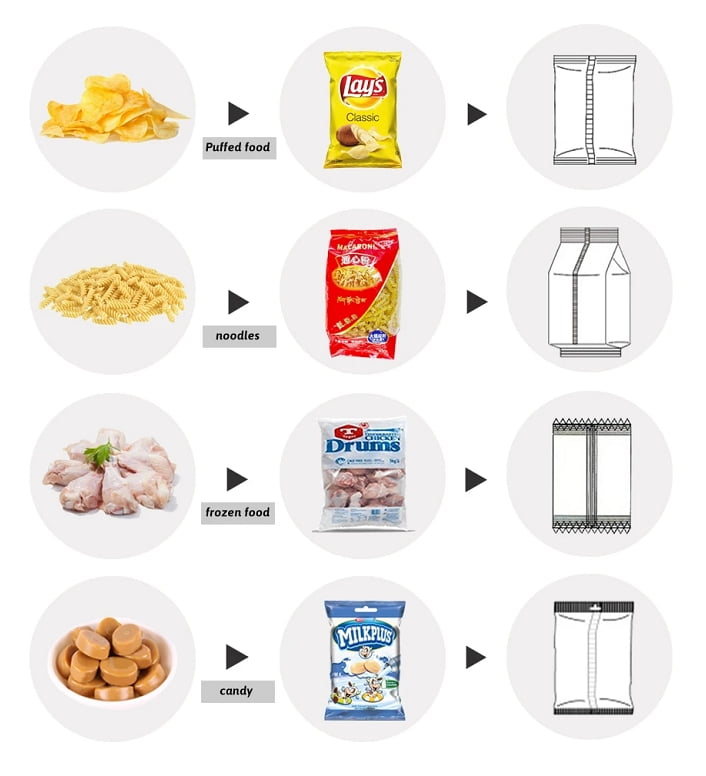

Type of Packaging Machine for Food

Packaging for food accounts for a large share of the packaging industry. High-tech packaging machines are everywhere today, and they are becoming more and more automatic.

Premade Pouch Packaging Machine

Compared to traditional packaging machines, this machine is relatively new. It uses pre-made pouch to complete the packaging. The machine automatically picks up the premade bags and opening-filling-sealing, Under certain circumstances, there is sometimes dust removal, Nitrogen filling and other processes. Rotating and horizontal machines are the two main types. In terms of function, they are similar. This video demonstrates how the rotary premade pouch packaging machine packs snacks:

There is a zipper pouch in the video above that you may have noticed. This is one of the advantages of the premade pouch packaging machine. Premade pouches can be designed with many complex designs since they are made in advance, including re-closeable pouches, spout pouches, zipper pouches, squeezed-neck pouches, etc. As a result, your products will stand out on supermarket shelves and increase sales, but such machines will also be more expensive, including the cost of the machine itself and packaging consumables.

Vertical Form Fill Seal Machine

VFFS (Vertical Fill & Seal Machine) is an old-school packaging machine. Filling and sealing are done vertically using a rollstock. Watch the video we shot below to understand its working principle more intuitively:

There is a great deal of similarity between the packaging ranges of the Premade Pouch Packing Machine and the Form Fill Seal Machine. Many people will hesitate in these two machines. You can read Premade Pouch Packing Machine VS Form Fill Seal Machine, Which one should you choose? to understand the difference In order to better choose the machine you need.

Horizontal Form Fill Seal Machine

Hffs is a horizontal form fill and seal machine (HFFS) that was developed almost at the beginning of automated packaging. It is similar to VFFS. Instead of using Rollstock, it uses horizontal Rollstock. The packaging speed of HFFS is very fast except for its robot catch mode. However, it can only pack certain large pieces of individual materials, such as bread and whole meats. The following video shows the process of packaging sausage:

At the same time, we have made some special modifications to our HFFS machines, which can be used as packaging for medicines as well as for cards. The video is as follows:

Vacuum Sealer

When food is packaged using these machines, it has an airtight seal, which allows it to be preserved for 3-5 times longer than if it was stored in plastic bags or other containers. It is common for manufacturers to use clear film so that their customers can see what they are buying and consuming. Furthermore, the plastic allows the food inside to be kept at a constant temperature – resulting in less food waste, as the likelihood of food spoiling is greatly reduced.

Work Process of Food Packaging Machines

The specific operation of a food packaging machine may vary depending on its design and functionality, but here is a general overview of how it works:

Product Feeding

Food products are either manually or automatically fed into the packaging machine. The process involves loading bulk quantities into hoppers or putting individual items on conveyor belts.

Product Orientation and Alignment

In order to ensure that the food products are positioned correctly for packaging, the machine may align or orient them according to the packaging requirements. This can be done using sensors, guides, or mechanical mechanisms.

Packaging Material Supply

Plastic films, laminates, or trays are used as packaging materials in packaging machines. These materials are supplied to the machine and unwound or formed as needed.

Forming and Filling

As the packaging material is formed into desired shapes, such as bags or trays, and filled with food products, the packaging machine fills these structures with food. The filling system can be vertical or horizontal, volumetric or weigher-based, or custom-designed.

Sealing

Once the packaging is filled with the food products, the machine seals the packaging material to create a secure and airtight seal. The sealing method can include heat sealing, ultrasonic sealing, or other sealing techniques depending on the packaging material and product requirements.

Coding and Labeling

Some food packaging machines are equipped with coding or labeling systems that apply date codes, batch numbers, or product labels onto the packaging. This can be done using inkjet printers, thermal transfer printers, or other printing methods.

Discharge and Packaging Collection

Once the packaging process is complete, the finished packages are discharged from the machine onto a conveyor belt or into bins for collection and further processing, such as boxing or palletizing.

The factors that need to be considered when selecting the machinery

The nature of the product

Identifying the product’s nature is the first step in choosing the right packaging machinery. Is it a liquid, a powder, or a solid? Each type of food product will require different packaging and, as such, different machinery. When packaging a liquid product, it must be packaged in a container that will not leak, while when packaging a powder product, it must be packaged in a container that can be sealed tightly to prevent spills.

It’s crucial to assess the sensitivity of the food product to factors like temperature, pressure, and handling during packaging. Some products may require specialized machinery to maintain their quality and freshness.

Packing speed

The second factor to consider is packing speed. What is the number of food products that need to be packaged per minute? The answer to this question will help determine the type of packaging machinery that is best suited for consumers’ needs.

Budget

The main factor determining a company’s choice of packaging machinery is its budget. In addition to the cost of machinery, packaging materials must be considered.

Packaging Material Compatibility

In addition to considering the nature of the product, it’s important to ensure that the packaging machinery is compatible with the chosen packaging materials. For example, some machinery may work better with certain types of plastics or biodegradable materials.

Effortless operation

It is also important to consider how easy it is to operate the system. Easy-to-use and easy-to-maintain machinery is ideal for companies. It will minimize downtime and keep costs low.

Flexibility

Last but not least, companies should consider the flexibility of the packaging machinery. Their decision will depend on whether they need a machine that can package a variety of food products or a machine that is specifically designed for one type of food.

Takeovers

Now that you understand the different types of food packaging machines and process of packaging foods, it’s important to select the right machine for your business.

So, what type of food packaging machine is best for your business? That answer depends on the products you are looking to package and the level of automation you need.

If you are unsure which machine would be a good fit for your company, contact Bengang Machine.

At Bengang Machinery, we can help you find the perfect machine for your needs. We have a wide selection of machines and knowledgeable staff who can answer any questions you may have about selecting the right packaging machine for your business.

Contact us today to get started!