Meat Wrapping demands optimal shelf life, hygienic construction, and peak productivity and efficiency for operations. Our solutions cater to all types of meat—whether fresh, chilled, or frozen; hamburgers; or cured, smoked, or salted varieties. We offer packaging on various machines including thermoformers, tray sealers, flow wrappers, vertical baggers, and stretch machines. With a broad range of automation options, we can help design any packaging system, from standalone setups to fully integrated lines. Meat Wrapping encompasses a vast array of options and solutions, and we are equipped to assist with every possibility. Any product. Any cut. Any style.

Modified Atmosphere Packaging (MAP) for Meat

The purpose of modified atmosphere packaging (MAP) is to prolong the shelf life of food products. MAP reduces or removes oxygen from the packaging, which is essential because oxygen accelerates spoilage. It promotes bacterial growth, triggers lipid oxidation reactions, and increases respiration rates, all of which contribute to spoilage. In this process, the air inside the package is substituted with specific gas mixtures that enhance the longevity of the product. Common gases utilized in MAP include carbon dioxide, oxygen, and nitrogen. Nitrogen is particularly important as it inhibits oxidation and helps keep the package from collapsing. This technique involves gas flushing, where a stream of gas replaces the air, diluting it before the package is sealed.

Vacuum Meat Wrapping

Vacuum packaging for meat involves the elimination of air and its impurities before the package is sealed. This method starts by heating and shaping the packaging film into the required form, followed by placing the products into the packaging either manually or through automated systems. After introducing the products, all air and particulates are removed, and then the packaging is sealed. Vacuum packaging offers numerous advantages, including extended shelf life, enhanced product protection, preservation of flavor, and prevention of mold and bacteria growth. This method is also cost-effective and compatible with both rigid and flexible types of packaging.

Vacuum Skin Packaging (VSP) for Meat

Skin packaging involves covering the product and any exposed material surfaces with a top film. The process starts with applying an adhesive to the backing material, which is typically corrugated cardboard or paperboard. The product is then sealed with the film using heat, and a vacuum removes the air to prevent spoilage. This packaging technique is beneficial for a variety of products including seafood, fresh meats, poultry, cheese, and ready meals. Advantages of skin packaging include prolonged shelf life, preserved flavor, clear visibility of the product, capability for vertical display, and suitability for both flexible and rigid support structures. This method is popular in retail environments, allowing consumers to view the product clearly without opening the packaging. Skin packaging can be performed using either a thermoformer or a tray sealer.

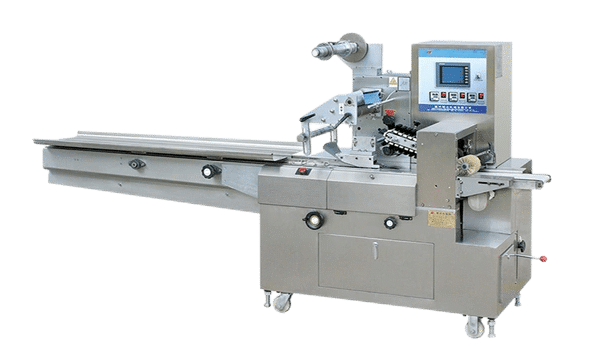

Flow Vaccum Meat Wrapping

Flow Vaccum technology enhances the efficiency of plastic film usage compared to traditional oversized vacuum bags. This process starts with products being indexed on the infeed conveyor, where each bag is customized to the product’s specific length to reduce waste. The feeding line is uniquely designed to avoid seal contamination, ensuring products are transferred smoothly from the conveyor to the film.

Loading film on Flow Vaccum machines is straightforward, and the newly model boasts a fully sanitary design with capabilities for thorough washing. Flow Vaccum machines are equipped with Lintyco® controls provided by Rockwell Automation, offering reliable and precise operations.

Stretch Seal Packaging for Sausages

Stretch seal packaging, implemented with a tray sealer, involves heat sealing the film to the tray’s flange or upper edge rather than encasing the entire tray. This sealing method effectively prevents leakage and lowers material costs. Stretch Seal is particularly suitable for poultry products due to its leak-proof properties and the exceptionally clear visibility it provides. Additionally, this technique removes the necessity for shrink tunnels, which some systems use to heat and shrink the film tightly around the product.

Lintyco on Tray Packaging for Meat

Lintyco technology enhances traditional skin packaging by incorporating a second skin that is tight and form-fitting, sealing directly to the product’s edge for additional support. This method significantly reduces waste with zero film scrap and uses up to 38% less top film compared to standard skin packaging. Additionally, it allows for a 20-30% increase in production speed, producing more trays per minute than conventional methods. Darfresh packaging is applicable to both tray sealing and thermoforming processes, making it ideal for products containing liquids. The technology features an easy-open film, ensures clear product visibility, provides superior oxygen barriers, and helps extend the product’s shelf life.

Conclusion

In the diverse world of Meat Wrapping, our comprehensive range of methods—from MAP and vacuum packaging to skin and Flow Vac technologies—ensures that we can meet the specific needs of any meat product with precision and care. These technologies not only extend the shelf life of meat products but also enhance safety, maintain flavor, and improve marketability with clear, appealing packaging. Whether it’s reducing waste with Darfresh technology or simplifying the packaging process with Flow Vac machines, our innovative approaches provide superior packaging solutions that cater to the evolving demands of the food industry. We are committed to delivering systems that maximize efficiency, minimize environmental impact, and provide the highest quality packaging solutions for all types of meat products.Contact Lintyco experts to help Now!