The flexible pouch packing machine has become increasingly popular in the food packaging industry, particularly for potato chips. This innovative technology has revolutionized the way businesses package their products, offering a wide range of benefits to both manufacturers and consumers.

Understanding the technical aspects of packaging machinery can be challenging for those without a background in engineering or manufacturing. This can make evaluating machines difficult or deciding which features are important for your specific needs. In this article, we will explore the reasons behind the popularity of flexible pouch-packing machines for potato chips and why they are the preferred choice for many businesses.

Types of packaging for potato chips

There are many types of packaging chips, all based on moisture insurance to ensure the taste and quality of chips, which can be mainly divided into the following categories:

- aluminum foil bags: this is a common and classic type of packaging, aluminum foil bags can effectively protect potato chips from factors such as moisture and oxidation.

- plastic bag: plastic bag is also a common type of packaging, it is lightweight and affordable, usually used for small packages and portable food.

- canned potato chips: this type of packaging can ensure the integrity of the chips, to avoid chips broken, and can be reused, very popular with consumers.

- boxed chips: boxed chips are usually used for gift boxes or special occasions, the appearance of gorgeous atmosphere, suitable for gift giving.

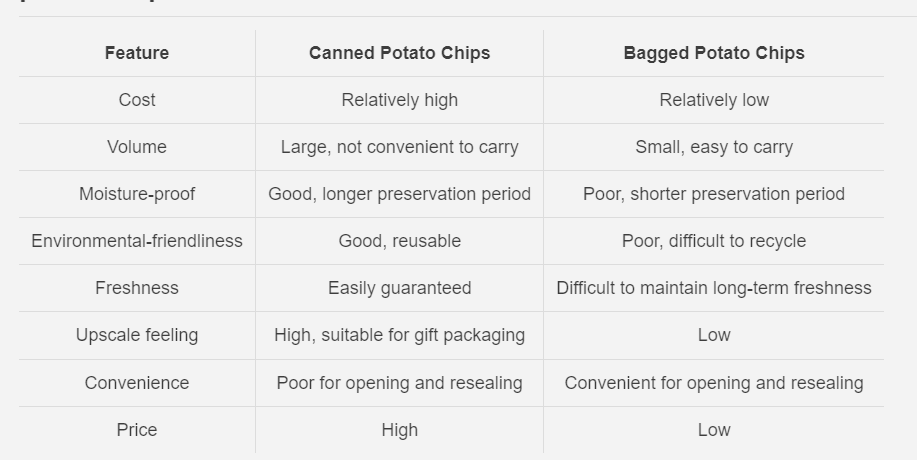

The advantages and disadvantages of bagged potato chips and filed potato chips

Types of Flexible Packaging Equipment

There are several types of potato chips packing machines available, including vertical and horizontal packaging machines. Vertical packaging machines are more suitable for single-serve portions, while horizontal machines are ideal for larger packages. Additionally, some machines use high-quality materials to ensure that the potato chips maintain their freshness and crunchiness.

Vertical Form Fill&Seal Machines for potato chips

VFFS machine (Vertical Form Fill Seal machine) is commonly used for packaging bulk foods such as particles and powders.

Its working principle is as follows:

- The packaging material (usually plastic film) is softened and stretched into a tubular shape inside the VFFS machine, which forms the packaging bag.

- The bottom of the packaging bag is sealed by hot sealing or cold seal sponge to form a vertical empty bag.

- Bulk food (such as potato chips, biscuits, etc.) enters the empty standing bag from the top through the conveying pipeline. The VFFS machine uses a weighing meter to control the product weight of each bag to ensure the product weight is consistent.

- The filled packaging bag is sealed by a heat-sealing knife and a pressure-sealing strip. After this step is completed, a packaging bag containing a fixed amount of product is formed.

- The packaged product is then subjected to subsequent processes such as metal detection, coding, and packaging as it moves along the production line.

- The finished product packaging bag will be output to the sorting and packaging workshop, waiting to be sold on the market.

Therefore, the VFFS machine achieves automatic weighing and packaging of bulk food through three processes: bag forming, bag filling, and sealing. It is efficient, hygienic and accurate, and is widely used in the food industry.

Horizontal Form Fill&Seal Machines for potato chips

HFFS machine (Horizontal Form Fill Seal machine) is also a kind of equipment used for packaging bulk food. Its working principle is similar to VFFS machine (Vertical Form Fill Seal machine), but the direction is horizontal.

The process flow is as follows:

- The packaging material (usually plastic film) is softened and stretched into a strip shape inside the HFFS machine, which forms the packaging bag.

- The packaging bag is sealed at both ends and the bottom by hot sealing or other methods to form a long empty bag.

- Bulk food enters the empty long bag from the side or bottom of the packaging bag through the conveying pipeline. The HFFS machine uses a weighing meter to control the product weight of each bag to ensure the product weight is consistent.

- The filled long packaging bag is sealed by a heat sealing knife and a pressure sealing strip to cut and seal the opening, forming a single packaging bag containing a fixed amount of product.

- The packaged product is then subjected to subsequent processes such as metal detection, coding and packaging as it moves along the production line.

- The finished product packaging bag will be output to the sorting and packaging workshop, waiting to be sold on the market.

The main differences between the HFFS machine and the VFFS machine are as follows:

1) The packaging bag of the HFFS machine is a horizontally formed long bag, while the packaging bag of the VFFS machine is a vertically formed short bag.

2) The bag filling and sealing of the HFFS machine are performed horizontally, while the process of the VFFS machine is in a vertical direction.

3) The speed of the HFFS machine is generally faster and the output is higher than that of the VFFS machine.

Premade Pouch Potato Chips Packaging Machines

Premade Pouch Packing Machine is a device that fills bulk food into pre-made vertical packaging bags and seals them.

Its working principle is as follows:

- Bags are made beforehand by a machine and put on a conveyor for packing. The packaging bag is usually made of plastic film and has an opening at one end.

- Bulk food enters the pre-made packaging bag from the top through the conveying pipeline. The premade pouch packing machine uses a weighing meter to control the product weight of each bag to ensure consistent product weight.

- The filled pre-made packaging bag is sealed by a heat sealing knife and a pressure sealing strip. After this step is completed, a pre-made packaging bag containing a fixed amount of product is formed.

- The packaged product is then subjected to subsequent processes such as metal detection, coding, and packaging as it moves along the production line.

- The finished product packaging bag will be output to the sorting and packaging workshop, waiting to be sold on the market.

The working principle of the premade pouch packing machine is simple, mainly using pre-made packaging bags for quantitative bag filling and sealing. Compared with VFFS machine and HFFS machine, its advantages are:

1) The packaging bags are produced in advance on a separate bag-making machine, and the packaging machine only needs to fill and seal the bags, simplifying the structure of the packaging machine.

2) The packaging speed is relatively fast because there is no need to stretch and form the packaging bags on site.

3) It reduces the consumption of film, and the packaging bags can be precisely made, reducing waste.

However, the disadvantage of premade pouch packing machine is that the packaging bags need to be produced in advance, limiting the efficiency of the packaging machine if production cannot keep up. The packaging bags can be customized by us online.

Packaging Auxiliary Parts to Choose

In terms of the technical details, a potato chips packing machine typically consists of a conveyor belt, weigher, bag maker, sealing machine, and coding machine. The conveyor belt transports the potato chips from the production line to the weigher, which accurately measures the weight of each package. The bag maker then produces the packaging, and the sealing machine heat-seals the packages shut. Finally, the coding machine prints details such as the expiration date or batch number on the package.

Are Chinese Packing Equipment Supplier Reliable?

If you’re interested in purchasing a potato chips packing machine, there are a few things you should keep in mind:

- Capacity: Decide how many chips per hour you need to pack and choose a machine that can handle that amount. Check the machine’s specifications for bag capacity per minute or hour before deciding which one to choose.

- Bag size: Choose the right bag size for your potato chips by checking the machine’s maximum and minimum sizes before buying.Remember, bigger bags mean more time to pack due to machine capacity.

- Quality: Look for machines made from high-quality materials that are easy to maintain and durable. You’ll want a machine that can operate smoothly and produce high-quality packages consistently over time.

- Price: Potato chips packing machines can vary widely in price, so determine your budget in advance. Consider purchasing a used machine if your budget is limited, but always make sure to inspect it carefully before making a purchase. You can also consider leasing or financing options to spread out the cost over time.

- Manufacturer & Warranty: Choose a machine from a reputable manufacturer with a strong track record of customer support. Be sure to read reviews and testimonials to get an idea of what other customers think of the company and its products. Additionally, always check the warranty offered, as you’ll want to be covered in case of any issues or defects.

- Download the file and check more detail.

Conclusion

Flexible pouch packing machines for potato chips are popular because they have many benefits. Their packaging design is excellent. It protects the chips, reduces waste, and saves money. It is also easy for customers to use and can be customized.

Vertical apparatuses are conventionally employed for single-serve portions because they can yield smaller pouches, with each pouch encompassing one serving of potato chips. In contrast, horizontal mechanisms are better suited for larger pouches, which can contain multiple servings of potato chips.

If you use pre-made bags, pick a machine that works with their size and shape, whether it’s vertical or horizontal. Check the machine’s specs before buying because some can pack both vertical and horizontal bags.

In summation, if you are employing pre-made bags, it is essential to select a machine that is compatible with the bags you mean to utilize, regardless of whether it is a vertical or horizontal apparatus.