If you’re looking for a granular packing machine , the variety of options available in the market may overwhelm you. Investing in a suitable machine can be a significant decision for your business, impacting production efficiency, tablet quality, and overall costs. With so many factors to consider, including machine types, features, and applications, it can be challenging to know where to start.Hope you find your answer here.

1. Introduction : Granule Packing Machines

Granule packing machines is also called granule filling machine ,granule packaging machine or granule sealing machine. It is an automatic equipment specially designed for measuring, packing and sealing granular substances, mainly used for packing and sealing granular substances in the fields of food (such as nuts, cookies, candies), chemicals (, pharmaceuticals, etc.). The machine usually adopts advanced sensors and control systems to ensure packaging accuracy and stability, and precise dosing control.

2. Where to Buy Granule Packing Machines

Purchasing a granule packing machine can be a hard task for first time buyer and Experienced Buyer .With the development of packing machine available in the market, Here are 3 tips on where to buy a granule packing machine:

- Online platforms: B2B E-commerce websites like Alibaba, often have listings for granule packing machines from various manufacturers and suppliers. These websites offer a wide range of options and allow you to compare prices and specifications easily.

- Local dealers: You can also find granule packing machines through local dealers near you.These supplier can provide after-sales support and may offer machine installation and maintenance services in time.

- Trade shows and expos: Industry trade shows and expos are great places to find granule packing machine manufacturers and suppliers. By attending these events, you can see the machines in action and directly interact with manufacturers and dealers.

3. Granule Packing Machines Near Me

There is few growing market for granule packing machines, with several manufacturers and suppliers offering their products in the country.

Some of the top companies providing granule packing machines in Nigeria include:

- Emel Group: Emel Group is one of the leading companies in Nigeria dealing with mechanical, electronic, plastic and chemical products. The company’s packaging machinery products include filling machines, sealing machines, filling machines, etc. 2.

- Nichemtex Industries Limited: Nichemtex Industries Limited is a Nigerian packaging machinery manufacturer that produces PET bottle production lines, as well as a wide range of packaging machinery.

- Duravant: Duravant is a US-based company that provides packaging, automation and process equipment worldwide. The company has a branch in Nigeria and provides packaging machinery and services. 4.

- La Mancha Company: La Mancha Company is a company that provides packaging and printing solutions. The company deals in accessories, equipment and services to provide customized packaging machinery to its customers.

Some top companies providing granule packing machines in Pakistan include:

- Makrotec: Makrotec is a leading packaging machinery manufacturer in Pakistan, specializing in providing filling, sealing and packaging solutions. Their product range includes liquid filling machines, solid filling machines, capsule filling machines, etc.

- Garments Machinery Solutions: Garments Machinery Solutions is a Pakistani company that provides textile and packaging machinery. They provide automatic packaging machines, printing machines, sewing machines and other equipment for the textile and garment industry.

- Shabbir Packaging Industries: Shabbir Packaging Industries is one of the leading packaging companies in Pakistan that offers various types of packaging materials and machinery. Their products include corrugated carton lines, case sealers, tape sealers, etc.

- Kamran Engineering Industries: Kamran Engineering Industries is a manufacturer specializing in food and beverage packaging machinery. They produce a variety of filling machines, sealing machines, labeling machines, etc. to provide solutions for the food industry.

Some top companies providing granule packing machines in India include:

- Bosch Packaging Technology India: A leading global provider of packaging technology solutions with its parent company based in Germany, the company’s Indian subsidiary also offers high-quality packaging machinery and solutions.

- Nichrome India Ltd.: Established in 1948, this company is one of the largest manufacturers of packaging machinery in India. The company’s products include automated packaging machines, canning machines, filling machines, weighing machines, etc.

- PMW Industries: Established in 1992, this company specializes in the production of packaging machinery. The company’s products include automatic sealing machines, automatic filling machines, automatic filling machines, etc.

- Om Chamunda Enterprises: Established in 2011, this company is a fast growing packaging machinery company in India. The company’s products include automatic sealing machines, automatic filling machines, automatic label attaching machines, etc.

Some top companies providing granule packing machines in China include:

1.Hangzhou Youngsun Intelligent Equipment Co., Ltd.: Hangzhou Youngsun Intelligent Equipment Co., Ltd. is one of the leading packaging machinery manufacturers in China, mainly producing various types of sealing machines, case sealers, labeling machines, etc.

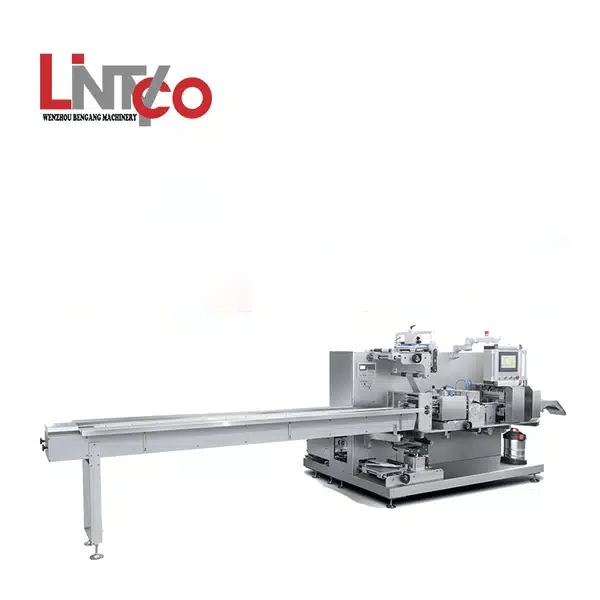

- Wenzhou Bengang Machinery Co., Ltd.: is a 15 years manufacturing experience company, mainly produces bag feed packing machine, pillow packing machine, granule packing machine, powder packing machine, packing machine, filling machine, the website is www.lintyco.com

- Redpack Packaging Machinery: Redpack Packaging Machinery Co., Ltd. is a manufacturer in China that specializes in high speed packaging machinery. They produce all kinds of heat shrink packaging machines, horizontal packaging machines, vertical packaging machines, etc.

China and India, Nigeria, Pakistan and other countries have different advantages and disadvantages in the field of packaging machinery. The following is a comparative analysis:

Disadvantages of Chinese packaging machinery:

- Processing quality and brand reputation: There is some variation in processing quality and brand reputation in China’s packaging machinery industry. Some manufacturers may face challenges in quality control and after-sales service.

- Intellectual property issues: China’s packaging machinery industry also faces challenges in intellectual property protection and technological innovation. Some companies may have problems with intellectual property infringement or technology copying.

In comparison, purchasing packaging machinery in China has the following advantages: - Customized solutions: Some Chinese packaging machinery companies have the advantage of providing customized solutions with specialization in specific areas.

- Social and cultural adaptability: These Chinese companies may have a better understanding of the local market and customer needs and can provide products and services that are more in line with local culture and customs.

Disadvantages of packaging machinery in other countries: - Technology level: Compared with China, the technological level of packaging machinery in other countries may be relatively backward and may lack advanced production technology and innovation capabilities.

- Supply chain and delivery capacity: The supply chain in other countries may be relatively weak, and the delivery time may be longer to meet the needs of some urgent orders.

In general, China has a greater advantage in the packaging machinery field, but packaging machinery companies in other countries also have their own characteristics and advantages. You can choose according to your needs.

How many type of automatic granule packing machine for sale

Small packing machine for sale.

Small packing machine is a mechanical device used to pack bulk products such as candy, coffee beans, seasoning into small sealed sachets or pouches. Small packaging machine can realize automatic filling, dosing, sealing and bag cutting functions, easy to operate. Small packaging machine for sale has the advantages of high automation, easy operation and stable product quality, which is especially suitable for small and medium-sized enterprises.

Pre-made bag packaging machine for sale.

Pre-made bag packaging machine refers to the bulk products into a pre-made vertical bag, and complete sealing equipment. Compared with small packaging machines, the advantage is that they are faster, as there is no need to make bags on site, only the bagging and sealing process. However, it also limits the flexibility of bag customization. Pre-made bag packaging machine for sale is suitable for companies with high production volume and high requirements for packaging speed.

VFFS machine for sale.

VFFS machine, known as vertical form fill seal machine, is a fully automatic machine that forms rolled packaging material into vertical bags and automatically completes bagging and sealing.VFFS machine has the advantages of fast packaging speed, high efficiency and good packaging quality, and is one of the most widely used machines in the food packaging industry.VFFS machine for sale is suitable for companies with high degree of mechanical automation and need for bulk production.

HFFS machine for sale.

HFFS machine is called Horizontal Form Fill Seal machine, its working direction is horizontal, forming the rolled packaging material into long bags and then automatic bagging and sealing. Compared with the VFFS machine, the HFFS machine has a smaller footprint and a simpler and more compact mechanical structure, and the HFFS machine for sale is more suitable for companies with limited production line layout. The product range is also more homogeneous and suitable for customized production of specific packaging specifications.

Auxiliary equipment of granule packing machine

Multi-head combination refers to the configuration of multiple heads with the same or different functions on a production line to complete the continuous production process. For example, a packaging line is equipped with multiple dosing and bagging heads, multiple heat sealing heads, etc. The use of multi-head combination machine can improve production efficiency and capacity, especially for high-speed and bulk production lines.

The multi-head combination machine needs to have an automatic mechanism design, which can realize the orderly connection and stable transmission of heads to ensure the coherence and synchronization of production process. At the same time, it also needs to have detection and discrimination functions, which can quickly locate when there is a problem with the head and reduce the defects of bagging or sealing caused by head failure.

Coding machine is used to print the production date, batch number, bar code and other information on the bag or carton. It can automatically print the preset coding content on each packaging container.

The coding machine is mainly composed of printing mechanism, conveying device, control system, etc. The printing mechanism uses inkjet printing, thermal printing or laser marking to complete the printing work. The conveying device sends the packaging containers to the printing position in sequence to complete the coding. The control system can set and adjust the printing content and position, etc.

The coding machine plays an important role in the food packaging production line, which can realize the whole quality control and traceability management of the product. The coded packaging is also more convenient for circulation and sales.

Sealing device is used to complete the bag mouth closure or seal sealing machinery. It is heated and cooled in such a way that the molecules of the packaging material undergo physical changes and the two pieces of material or the mouth of the bag are actually bonded or fused together.

Common sealing methods are heat sealing, ultrasonic sealing, high frequency sealing, etc. Heat sealing is the most common way, is the use of heating elements near the packaging bag material heated to its melting point, and apply pressure to make the material fusion. Ultrasonic sealing and high-frequency sealing is the use of sound waves and high-frequency current to make the material quickly heated and molten, with high efficiency.

Sealing equipment is one of the key machinery in the food packaging line, which directly affects the shelf life and appearance quality of the product. The choice of high-quality sealing equipment plays an important role in product safety and market competitiveness.

8. How Much is Sachet Granule Packing Machine Price

Sachet packing machines are a kind of granule packing equipment specifically designed for packing granules into small sachets. Like granule packing equipment, sachet packing machine prices can vary a lot based on things such as capacity, features and the maker’s reputation. Usually, granule packing equipment can cost from a few thousand to tens of thousands of dollars, depending on your business’s specific needs.

To get the best value from your investment, consider these points when comparing granule packing equipment prices:

- The speed and precision of the machinery

- The quality and durability of the machinery’s parts

- The availability of after-sales support and maintenance

- The reputation of the manufacturer

5Kg -50Kg Big Bag Grains Weighing and Packing Machine

The 5Kg -50Kg grains weighing packing machine specializes in granular and irregular materials, such as granules, granule-powder mixtures, strip shape materials, block shape materials, threadlike tobacco materials, and other materials’ quantitative packing.

Some materials are as follows: fertilizers, feed, Chinese herbal medicines, Chinese medicine granules, premix, washing powder, casual snacks, candies, melon seeds, peanuts, salt, monosodium glutamate, chicken powder, seeds, grains, hardware, and other granular materials.

what is the type of granule material

Granular packaged products in food industry may include:

- Snack particles: such as chips, popcorn, nuts, candy and other tiny snack granules.

- Grain and breakfast granules: such as granola, cereal granules, cereal topping granules, etc.

- Dried fruit and vegetable granules: such as raisins, cranberries, dried mangoes, dried carrots and other granular dried produce

- Granular seasonings: such as salt granules, pepper granules, garlic granules, onion granules and other granular flavorings.

- Edible grain and legume granules: such as spiral pasta, granulated beans, corn, etc.

- Pastry and bread granules: such as breadcrumbs, chocolate chips, sugar decorations, etc.

- Frozen food and fast food granules: such as frozen dumplings and other granular frozen products.

- Noodle and powder granules: such as granular vermicelli, fine flour, noodle flakes, etc. for effortless cooking. Note that granule packed goods vary extensively. Specific items depend on the food type and production method. When purchasing and consuming, follow the directions and food safety labels on the packaging and the relevant guidelines for storage and consumption.

Granular packaged products in chemicals may include:

- Powdered chemicals like dyes, pigments, additives, etc.

- Granular plastics such as plastic granules, granular fillers, etc.

- Granular fertilizers e.g. for nitrogen, phosphorus, potassium, etc.

- Granular catalysts for chemical reactions.

Granule packaging products in pharmaceuticals may include:

- Pharmaceutical granules: granules, mini-pills, coated granules, etc. commonly as tablets, capsules, oral suspensions, granule injections, etc.

- Herbal granules: Ground herbs made into granules and packed for convenience.

- Oral care granules: Like oral rinse granules, throat lozenges, etc.

- Medication sachets: Single or multiple use sachets of medication granules e.g. for individualized or children’s doses.

- Nutritional supplements: Granular vitamins, minerals, proteins, nutrients, etc.

Note that specific items and names differ per countries/regions. Follow the local rules and medical guidelines when buying and using.

Does the granule packaging machine support multiple packaging specifications to switch?

Some granule packaging machines can be adapted to different specifications by changing molds, adjusting parameters, etc. Be sure to ask before you buy a packaging machine, whether you can do this function. Of course, also pay attention to the maximum size and minimum size

How many bag type that you can choose

The packaging machine adapts to different packaging materials, such as plastic film, aluminum foil, and paper composite materials. Packaging forms include three-side-seal, four-side-seal, vertical bag and stand-up bag.

Zipper bags are perfect if you’re opening and closing a lot. Folks can easily get at the granules whenever they want, like for snacks or portions.

Three-side seal bags suit smaller bits that pour easily. Sealing them right keeps everything fresh and moisture-out.

Four-side seal bags work better for bigger bits that need stacking neatly. They give solid, storage- and display-friendly packaging.

Stand-up bags stand on their own, stack and show well, look great on supermarket shelves. The main thing is picking food-safe stuff with the info you need. Then focus on custom details that make you stand out:

The overall principle is first to ensure that the packaging material chosen meets food safety requirements and provides the necessary labeling and information. The second is in making good details to improve their competitiveness

How much packaging speed of the granule packaging machine, what are the main factors affected by?

A number of factors, including the nature of granular materials, bag specifications and materials, equipment configuration and adjustment. Depending on this factors, non-high-speed packaging machine is generally about 20 bags a minute vertical packaging machine is generally 30-60 bags, pillow packaging machine can be up to 180 bags a minute

what is the packing process with granule packing machine

It can automatically complete a series of operations such as metering, feeding, filling and sealing, and can be set up with functions such as printing code and counting according to needs.

Weighing : The quantity or weight of granular products is automatically measured according to the set parameters. Usually done with a vibrating disc or screw feeder in flush

Feeding : Automatic conveying or supplying of granular products into the hopper or storage tank of the packaging machine.

Filling : precise filling of the granular product into the bag by means of a set device or machinery

Sealing: Automatic heating or gluing of the bag opening closed using a series of mechanical actions.

Coding: Print identification codes on the package using inkjet or other types of marking equipment, as required.

What are the main components of the granule packaging machine?

Feeding device:The supply quantity of granular materials is controlled by adjusting parameters such as the rotational speed of the feeder and the speed of the conveyor belt to achieve the adjustment of different packaging capacities.

Weighing device: Usually a vibrating disc or a screw feeder is used to accurately measure the granular material according to the set weight by vibration or rotation.

Sealing device:There are two types of sealing devices: heat seal and press fit sealing, of which heat seal sealing is applicable to plastic film bags, while press fit sealing is applicable to paper or polymer composite bags.

Control system:The emergency stop button is an emergency stop device used to stop the machine immediately in case of emergency to ensure the safety of the operator.

Safety devices: safety door, emergency stop button, shortage of material alarm, overload protection

Granule packaging machines usually need to be calibrated and verified periodically to ensure that the packaging accuracy and performance meet the requirements and comply with relevant regulations and standards.

How to assess the reliability of the granule packaging machine?

The reliability of a granule packaging equipment can be assessed based on attributes such as service life, malfunction frequency, servicing and upkeep costs, alongside consulting actual user feedback and label prestige.

A pellet packaging apparatus’s din ordinarily necessitates fulfilling noise pollution regulations, which can be mitigated via sound muffling configurations, quake dampening procedures, and utilizing hushed constituents.

Whether there are fault self-acting cautions, the moment failures or irregularities surface, the mechanism will blare an audible alarm or exhibit an admonitory message to alert the operator to address them.

What are the requirements of the working environment of the granule packaging machine?

Granule packaging machine usually requires a clean, tidy working environment, the temperature between 10-40 degrees Celsius, humidity between 30-70%.

How much compressed air is required for the granule packaging machine?

Granule packaging machine usually requires compressed air pressure between 0.6-0.8MPa.

We hope this ultimate FAQ guide has provided you with valuable information on granule packing machines. With the knowledge gained from this guide, you should be better equipped to make an informed decision when purchasing a granule packing machine for your business.