Introduction

Introducing Lintyco, a brand that epitomizes precision and efficiency in the realm of high-speed packaging machines. Inspired by the relentless and vast sea, Lintyco promises to elevate production capabilities of its clients with automatic high-speed packaging machines that blend high accuracy with cutting-edge technology. This article delves into the unique aspects of Lintyco’s packaging solutions, exploring how these machines work, their key components, and the benefits they offer across various industries.

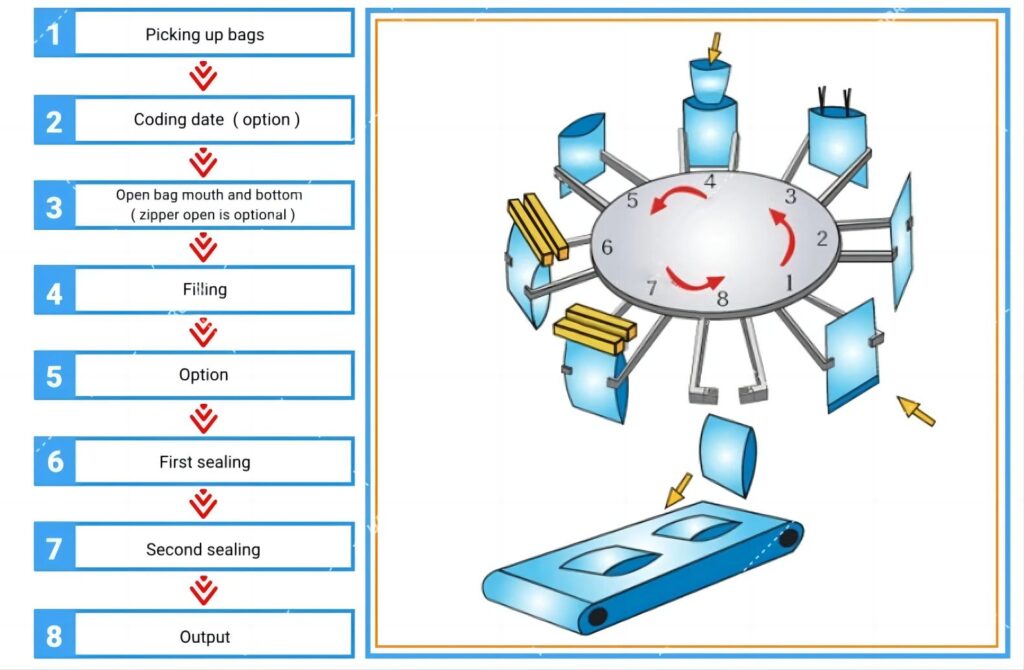

How High-Speed Packaging Machines Work?

High-speed packaging equipment are marvels of engineering designed for rapid production without sacrificing accuracy. The process begins with the automated feeding of products into the packaging system, where they are metered precisely before being packaged. Each package is then sealed securely and cut to size, preparing it for shipment or sale. The seamless integration of feeding, metering, sealing, and cutting ensures high efficiency and operational speed.

Key Components

The core of a high-speed packaging machine includes several critical components: the feeding system, metering system, sealing system, and the control system. These components work in unison to ensure that products are handled delicately yet swiftly, maintaining a consistent packaging quality that is crucial for consumer satisfaction and operational reliability.

Benefits and Applications

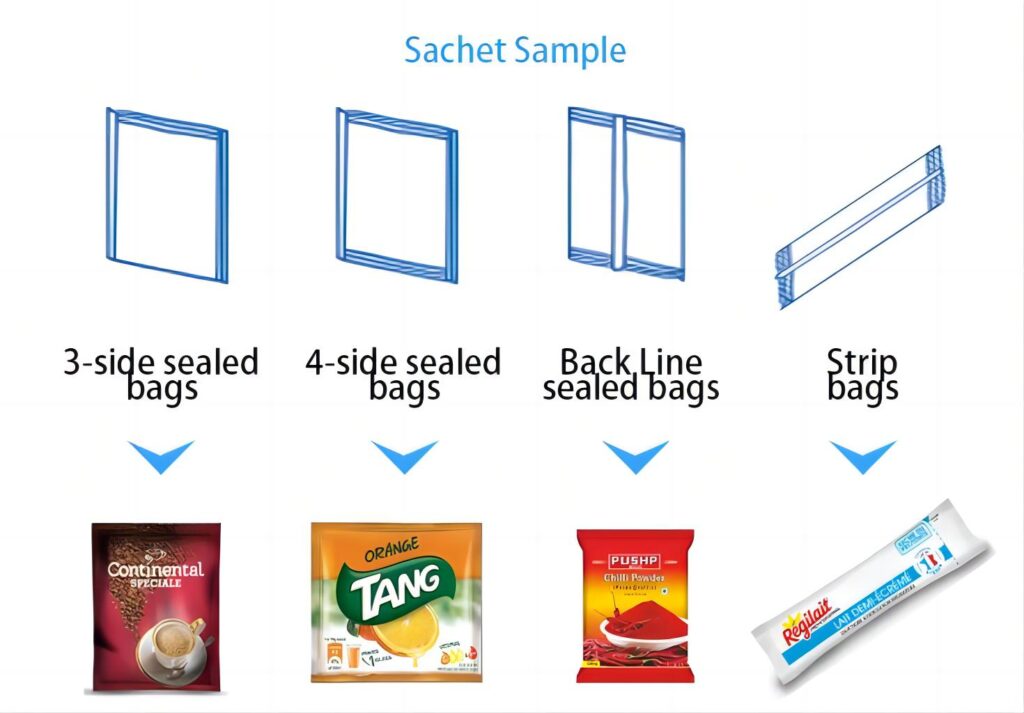

Lintyco’s high-speed case packer and packaging machines offer significant advantages, including increased productivity, reduced labor costs, and enhanced packaging quality. These machines find extensive applications across various sectors such as food and beverage, pharmaceuticals, cosmetics, and electronics, highlighting their versatility and essential role in modern manufacturing processes.

Texture

The texture of packaging plays a pivotal role in consumer perception and product protection. Lintyco machines are designed to handle a wide range of packaging materials, allowing for various textures that can be tailored to specific product needs or branding requirements, ensuring that the end product is not only well-protected but also appealing to customers.

Difference Between High-Speed Packaging Machines and Ordinary Packaging Machines

Contrasting high-speed machines with their ordinary counterparts, the differences are stark. Machines like speed pack machines offer vastly superior packaging speeds, greater throughput, and higher levels of automation and efficiency. These enhancements allow businesses to handle larger volumes of products more efficiently, significantly impacting overall productivity and operational cost-effectiveness.

| Difference | High Speed Packaging Machine | Ordinary Packaging Machine |

| packaging speed | The packaging speed has exceeded the traditional level and reached 3,600 packages per minute. It is more than 10% higher than traditional products. | Packaging speed can vary depending on product and bag size, usually between 2,000 bags per hour |

| Capacity | Have higher throughput, allowing them to handle larger quantities of products in a given time frame. | Lower throughput |

| Automation and Efficiency | Enable precise and efficient handling, filling, sealing and labeling processes to minimize downtime and maximize productivity. | The function is relatively simple and the level of automation is not high |

| flexibility | Can accommodate various types of packaging including bags, pouches, cartons, bottles, etc., providing a wider range of product packaging options. | Packaging form is relatively limited |

Market Demand and Significance

The demand for speed packaging solutions is driven by the need for efficiency and scalability in production lines. As industries continue to grow and consumer demands evolve, the ability to quickly package and distribute products becomes increasingly crucial. Lintyco’s solutions not only meet these demands but also contribute to sustainable operational practices by improving resource utilization and reducing waste.

Enhancing Brand Identity Through Innovative Packaging

In a competitive market, the packaging can significantly influence brand perception. Lintyco machines support innovative packaging designs that resonate with brand identity and consumer expectations, thereby enhancing brand visibility and market reach.

Sustainable Practices in High-Speed Packaging

Sustainability is no longer a choice but a necessity in manufacturing. Lintyco’s high-speed packaging machines are designed with sustainability in mind, using energy-efficient processes and materials that reduce the environmental impact, aligning with global efforts towards more sustainable production methodologies.

Conclusion

Lintyco is not just a brand; it’s a revolution in the packaging industry, inspired by the robust and ever-changing nature of the sea. With its state-of-the-art automatic high-speed packaging machines, Lintyco is set to transform production lines across industries, making them faster, more efficient, and more environmentally friendly. Embracing Lintyco means not only boosting your production capabilities but also committing to quality and sustainability in packaging.