Introduction

Poultry packaging machine (whole chicken packaging machine or meat packaging machine) is an automated packaging equipment specially used for poultry and its accessories. It ensures the freshness and sanitation and safety of poultry products during storage, transportation and sales through an efficient packaging process. The application of this equipment not only improves packaging efficiency and reduces labor costs, but also helps to improve the appearance and texture of the product and enhance market competitiveness.

The main functions of poultry packaging machines can be summarized as follows:

- Fresh-keeping effect: Through modified atmosphere packaging technology, poultry packaging machines can adjust the gas composition in the package and extend the shelf life of poultry.

- Improve efficiency: Automated operation reduces manual participation, improves packaging speed and overall production efficiency.

- Ensure hygiene: The closed packaging environment reduces external pollution and ensures the sanitation and safety of poultry.

- Easy to transport: The standardized packaging design facilitates the handling and transportation of poultry products and reduces losses during transportation.

- Enhance display effect: The exquisite packaging appearance helps to attract consumers’ attention and enhance the market appeal of products.

In the modern food processing industry, poultry packaging machines are increasingly used and have become one of the indispensable equipment for improving production efficiency and ensuring food safety. With the continuous advancement of technology, poultry packaging machines in the future will be more intelligent and automated, meeting the market demand for high efficiency, environmental protection and energy saving.

Types of Poultry Packaging Machines

1. Tray Sealers

Tray sealers are versatile and efficient for case-ready poultry packaging. They can handle various tray sizes and materials, offering options like Modified Atmosphere Packaging (MAP) and Vacuum Skin Packaging (VSP) to extend shelf life and improve product presentation.

2. Thermoformers

Thermoforming machines are ideal for high-volume production. They form the package from roll stock, fill it with the product, and seal it. These machines offer flexibility in package design and can incorporate MAP technology. Lintyco offers thermoforming solutions for both fresh and frozen poultry

3. Flow Wrappers

Flow wrappers, both horizontal (HFFS) and vertical (VFFS), are used for wrapping poultry products efficiently. The Lintyco flow wrapper is specifically designed for fresh poultry packaging, providing a cost-effective and sanitary solution

4. Vacuum Packaging Machines

Vacuum packaging machines remove air and contaminants before sealing, which helps preserve flavour and prevent spoilage. These machines are suitable for both flexible and rigid packaging and are used for products like whole chicken and chicken breasts

5. Stretch/Shrink Wrapping Machines

These machines provide a tight, clear wrap around the product, which is cost-effective and enhances product presentation.

6. Master Bag Machines

Master bag machines are ideal for case-ready applications, grouping trays into larger Modified Atmosphere packs to maintain maximum shelf life until retail display. This method also reduces labor costs and increases throughput.

7. Premade Pouch Packing Machine

Premade pouch packing machines are used for packaging poultry in premade bags. They are efficient and designed to handle wet and sticky products, making them suitable for various poultry products

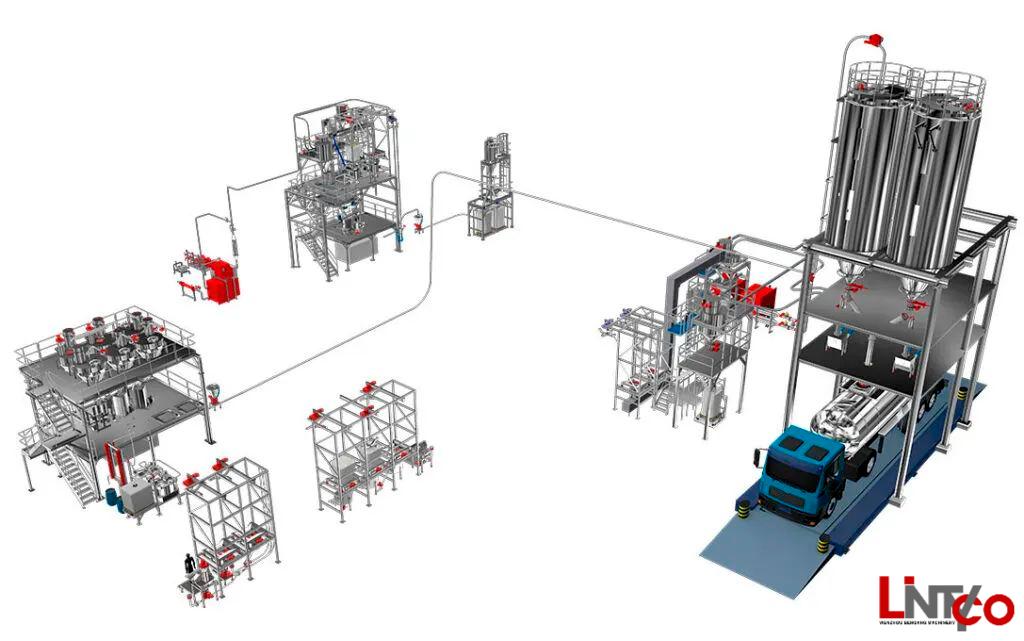

8. End-of-Line Solutions

End-of-line solutions, such as those provided by Lintyco, include tray forming, case erecting, and case packing machines. These solutions automate the final stages of the packaging process, ensuring efficient and secure packaging for shipping

How to Package Chicken

The operation process of the whole chicken packaging machine usually includes the following steps:

Pretreatment: The chicken is prepared for packaging after pretreatment steps such as cleaning and deboning.

Loading: The processed chicken is placed in the designated position of the packaging machine.

Packaging: According to the required poultry packaging solutions (vacuum, gas conditioning, etc.), the packaging machine automatically loads, packages and seals the packaging materials.

Post-processing: After packaging, the poultry products are either sent directly to cold storage or to the next step of logistics distribution.

Cleaning and maintenance: After the packaging process is completed, the packaging machine is cleaned and maintained as necessary to ensure the normal operation of the equipment and food safety.

The innovation points of the poultry meat packaging machine mainly focus on the improvement of the degree of automation, intelligent control, energy saving and reduction of consumption, as well as adapting to diversified packaging needs.

- Automatic loading: through the cooperation of infrared sensor and cylinder, it realises automatic loading of poultry meat, reduces manual input and improves efficiency.

- Intelligent control: Introducing intelligent control system to automatically adjust packaging parameters according to the size and shape of poultry meat to optimise the packaging effect.

- Energy-saving design: adopts energy-saving air-conditioning preservation technology to reduce energy consumption and ensure packaging effect at the same time.

- Diversified packaging: able to adapt to poultry meat products of different shapes and specifications, realising diversified packaging needs and meeting the market’s changing packaging requirements.

- Environmentally friendly material application: research and application of new environmentally friendly packaging materials to reduce the impact of packaging waste on the environment.

- Modular design: Adopting modular design concept, it is easy to maintain and upgrade, and prolong the service life of the equipment.

- Data tracking: Integrated data tracking system records key data in the packaging process, facilitating quality control and product traceability.

Each of these machines offers different benefits in terms of packaging style, production speed, shelf life extension, and product presentation. The choice of machine depends on factors such as the specific chicken product being packaged, desired shelf life, production volume, and retail presentation requirements.

Applications and Benefits

- Extended Shelf Life: Technologies like MAP and vacuum packaging help extend the shelf life of poultry products by reducing oxygen levels and preventing spoilage.

- Improved Product Protection: Leak-proof and durable packaging options protect the product during transport and storage.

- Enhanced Presentation: Clear and tight packaging improves the visual appeal of the product, which is crucial for retail settings.

- Increased Efficiency: Automation options reduce labor costs and increase production speed, making the packaging process more efficient.

Poultry packaging machines are widely used in various poultry processing enterprises, including but not limited to poultry slaughterhouses, poultry processing plants, central kitchens of fast food chains, and meat processing areas of large supermarkets. These places have different requirements for poultry packaging, and poultry packaging machines can provide customized solutions to meet packaging needs in different scenarios.

Poultry slaughterhouses

In slaughterhouses, poultry packaging machines are mainly used for the rapid packaging of fresh poultry that has just been slaughtered to reduce bacterial growth and extend the shelf life of meat.

Poultry processing plants

In processing plants, packaging machines are used to package processed poultry products, such as smoked poultry, poultry sausages, etc., in modified atmosphere or vacuum packaging to maintain product flavor and extend shelf life.

Fast food chain central kitchens

The fast food industry has strict requirements for food consistency and rapid supply. Poultry packaging machines ensure standardized packaging and rapid delivery of ingredients in this link.

Meat processing areas in large supermarkets

Poultry in supermarkets needs to attract consumers and ensure food safety. Packaging machines achieve beautiful and safe packaging in this link to enhance consumers’ desire to buy.

Depending on the application scenario, the poultry meat packaging machine may also need to integrate specific functions, such as automatic weighing, date printing, label affixing, etc., in order to meet diversified industrial needs.

Market Status and Development Trend of Poultry Packaging Machines

Market Status Analysis

As an important part of the food processing industry, the market demand for poultry packaging machines has been growing steadily with the increase in poultry consumption. According to market research data, global poultry consumption has increased at an annual rate of about 3% in recent years, driving the expansion of the poultry packaging machine market.

Market size

The current global poultry packaging machine market size has reached billions of US dollars, among which the Asia-Pacific region has become the largest poultry packaging machine market due to its large population base and rapid growth in poultry consumption.

Technological development

High-end poultry packaging equipment such as fully automatic modified atmosphere fresh-keeping packaging machines are favored by the market because they can effectively extend the shelf life of poultry and reduce food waste. According to statistics, the market share of fully automatic equipment has increased by about 15% in the past five years.

Geographical distribution

Due to the early start of the food processing industry in Europe and the United States, the technical requirements for poultry packaging machines are high and the market maturity is high. With the rapid economic growth and the improvement of food safety awareness in developing countries, the demand for poultry packaging machines is rapidly increasing.

Development Trend Forecast

Combined with the current market and technology development trends, the poultry packaging machine market will present the following characteristics in the future:

Improved automation level

With the advancement of Industry 4.0 and the development of intelligent manufacturing technology, poultry packaging machines will be more automated and intelligent, reducing manual operations and improving production efficiency and packaging quality.

Technological innovation

The application of new packaging materials and preservation technologies will continue to emerge, such as modified atmosphere packaging, vacuum packaging and other technologies will be further developed to meet the market’s higher requirements for food safety and quality.

Enhanced environmental awareness

The popularization of the concept of sustainable development will drive packaging machine manufacturers to develop more environmentally friendly packaging solutions, reduce the use of packaging materials, and reduce the impact on the environment.

Market demand segmentation

With the increase in consumer demand for food diversity, the poultry packaging machine market will be further segmented, and special packaging equipment will be developed for different poultry product characteristics to meet specific market needs.

Service model transformation

From single equipment sales to providing overall solutions and services, including equipment maintenance, technology upgrades and customized services, to enhance customer stickiness and market competitiveness.

According to a report released by a market research company, the global poultry packaging machine market is expected to grow at an average annual rate of 5% in the next five years, and the Asia-Pacific region will continue to lead the market growth.

Conclusion

Poultry packaging machine plays an increasingly important role in the modern food processing industry as an important equipment to improve production efficiency and ensure food safety. With the improvement of consumers’ requirements for food quality and safety and the continuous upgrading of the automation level of food processing, the poultry meat packaging machine market is expected to continue to grow.

When selecting a poultry packaging machine or chicken packaging machine , consider factors such as production volume, desired packaging style, product sizes and shapes, and specific requirements for shelf life and presentation. Many chicken manufacturers offer customizable solutions to meet the unique needs of poultry processors and distributors.

If you are unsure which machine would be a good fit for your company, contact Lintyco now.