Baby food packaging are essential for ensuring the quality, safety, and shelf-life of baby food products. These baby food machines are designed to handle various types of baby food, including purees, powdered formulas, and more, with precision and efficiency. This guide will provide a comprehensive overview of the different types of baby food packaging machines, their features, and considerations for selecting the right machine for your needs.

Safety and Quality Assurance

Ensuring the safety and quality of baby food is paramount. Packaging machines play a critical role in maintaining these standards through:

- Non-Hazardous Materials: Machines should use food-grade, non-toxic materials to prevent contamination.

- Sealing Techniques: Advanced sealing methods, such as hermetic seals, help preserve freshness and prevent leaks.

- Contamination Prevention: Features like enclosed filling systems and sterile environments minimize the risk of contamination during packaging.

Health Standards

Adhering to stringent hygiene standards is essential for baby food packaging machines:

- Cleaning and Disinfection: Machines should be designed for easy cleaning and equipped with automated cleaning cycles to ensure thorough disinfection.

- Regulatory Compliance: Packaging machines must meet food safety regulations, such as those set by the FDA or EU, ensuring that they are safe for handling baby food.

Environmental Protection and Sustainability

Sustainability is a growing concern in packaging:

- Eco-Friendly Materials: Using biodegradable or recyclable materials reduces environmental impact.

- Waste Reduction: Efficient machines minimize material waste during the packaging process.

- Carbon Footprint: Energy-efficient machines help lower the carbon footprint of production facilities.

User Friendliness

User-friendly packaging machines are crucial for efficient operations:

- Simplified Operation: Intuitive interfaces and easy-to-follow instructions make machines accessible to operators with varying skill levels.

- Quick Adaptation: Features that allow for rapid changes in packaging setups help companies respond swiftly to market demands.

Types of Baby Food Packaging Machines

Baby food packaging machines are designed to handle the specific needs of packaging various types of baby food, including purees, powdered formulas, and more. Here is a detailed overview of the main types of baby food packaging machines, their features, and applications:

Horizontal Form Fill Seal (HFFS) Machines

HFFS machines form, fill, and seal pouches horizontally. These machines are ideal for high-volume production and can handle a variety of pouch types and sizes. BG800z, designed for high-capacity production with a zipper pouch.

Features

- High-Speed Production: Capable of producing up to 300 pouches per minute.

- Precision and Accuracy: Servo-motorized systems ensure precise pouch movement and filling.

- Versatility: Suitable for various types of baby food, including purees and liquids.

Applications

4 side seal pouches,pillow pouches, and other flexible packaging formats.

Vertical Form Fill Seal (VFFS) Machines

VFFS machines form, fill, and seal pouches vertically. Vffs packaging machines are versatile and can handle both powdered and liquid baby food products.Lintyco VFFS multihead weigher machine, which can package fruits, vegetables, and other baby food items.

Features

- Efficient Packaging: Suitable for a wide range of pouch sizes and materials.

- Adaptability: Can be used for different types of baby food packaging, from powders to liquids.

Applications

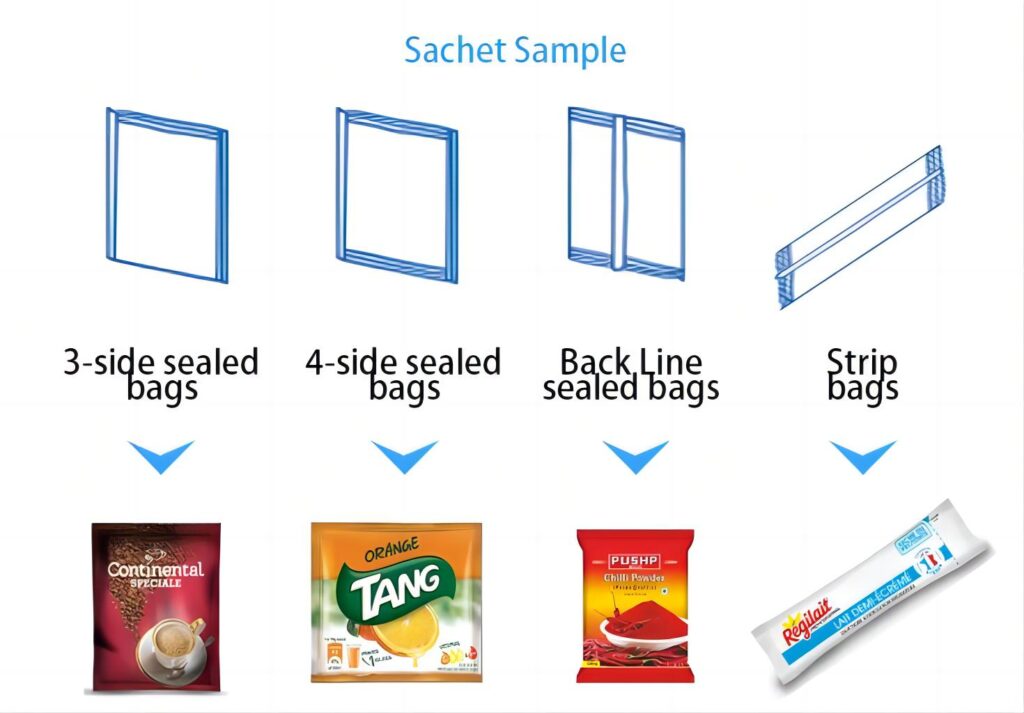

Sachets, pillow bags, and other vertical packaging formats.

Pouch Filling and Sealing Machines

Pouch packaging machines are designed to fill and seal pre-made pouches. They are ideal for small to medium production scales and offer flexibility in packaging types.Our baby food pouch filling machine, suitable for cooked, pasteurized, and cooled baby food products.

Features

- Modular Design: Allows for quick and efficient customization.

- High Quality: Robust construction with stainless steel components for hygiene.

Applications

Stand-up pouches, spouted pouches, and flat pouches.

Cup and Bottle Filling Machines

Bottle filling machines fill and seal containers (cups and bottles), often used for dairy-based baby foods and other liquid products.

Features

- Hygienic Design: Ensures cleanliness and safety during the packaging process.

- Hot-Filling Technology: Extends the shelf life of baby food products.

Applications

Cups, jars, and bottles for baby food, dairy products, and beverages.

End-of-Line Packaging Machines

Secondary machines handle the final stages of packaging, including sleeving, batch preparation, overwrapping, case forming, and palletizing.

Features

- Comprehensive Solutions: Integrate seamlessly into production lines to support branding and logistic requirements.

- Sustainability: Suitable for packaging with recycled materials like rPET or rPS.

Applications

Secondary packaging for retail-ready products, bulk packaging for distribution.

Key Features to Consider

Modern packaging machines incorporate innovative features to enhance functionality:

- Automation: Look for machines with high automation levels to reduce manual labor and increase production speed. Automated systems also ensure consistent quality and reduce waste.

- Intelligent Control Systems: These systems allow for precise control over packaging parameters, ensuring optimal performance.

- Adjustable Packaging Options: Machines that can adjust packaging size and material selection cater to different types of baby food, offering flexibility in production.

- Hygiene and Safety: Ensure the machine meets industry standards for hygiene and food safety, crucial for baby food products.

- Energy Efficiency: Opt for energy-efficient machines to reduce operational costs and support sustainability goals.

- Ease of Operation: Machines with user-friendly interfaces and easy maintenance are beneficial for smooth operations and quick adaptation by operators.

Automatic Packaging Solution for Baby Food

LIntyco Pack provides a variety of packaging machines, such as fully automatic packaging machines, bag-feeding packaging machines and granule packaging machines, suitable for different types of baby food (milk powder, puree and soy milk). Different packaging solutions are customized for different baby product needs. For example, baby puree packaging machines, nozzle-type jelly packaging machines and soy milk bag packaging machines, these equipment can efficiently complete packaging tasks.

In terms of design, in order to ensure the health and safety of infants and young children, milk powder packaging design must meet strict safety standards. This includes the use of safe and reliable packaging materials, reasonable design and construction, and advanced anti-counterfeiting technology. For example, Lintyco® aseptic packaging solutions can effectively extend the shelf life of food and ensure food safety.

Baby Food Market Trends

Understanding market trends is vital for staying competitive:

- Consumer Demands: There is a growing demand for convenient, eco-friendly, and safe packaging solutions in the baby food sector.

- Competitive Edge: By adopting machines that meet these trends, companies can enhance their product offerings and improve market competitiveness.

Incorporating these elements into your selection and use of baby food packaging machines can significantly enhance product quality, operational efficiency, and market responsiveness.

Conclusion

Selecting the right baby food packaging machine involves considering the type of food being packaged, production scale, and specific features like automation, hygiene, and energy efficiency. Leading manufacturer Like Lintyco Pack offer a range of machines tailored to meet the diverse needs of baby food producers, ensuring high-quality, safe, and efficient packaging solutions.

If you are unsure which machine would be a good fit for your company, Contact our experts now.