Giới thiệu

Trong thế giới phân phối gia vị không ngừng phát triển, hiệu quả và độ chính xác là tối quan trọng. Cho dù bạn đang xử lý hạt tiêu đen thơm, quế ngọt, thìa là Ai Cập hay nghệ tây kỳ lạ, quy trình đóng gói đóng vai trò quan trọng trong việc duy trì chất lượng và kéo dài thời hạn sử dụng. Hãy đến với máy đóng gói gia vị hiện đại—sự kết hợp tinh vi giữa công nghệ và chức năng được thiết kế để xử lý nhiều loại gia vị khác nhau một cách dễ dàng. Từ các hệ thống hoàn toàn tự động đến các giải pháp thay thế bán tự động, các máy đóng gói gia vị này đáp ứng nhiều yêu cầu đóng gói khác nhau, đảm bảo rằng gia vị của bạn được đóng gói liền mạch và an toàn.

Bài viết này đi sâu vào sự phức tạp của máy đóng gói gia vị, khám phá các loại, tính năng, lợi ích và ứng dụng của chúng để giúp bạn đưa ra quyết định sáng suốt cho doanh nghiệp của mình.

Các loại máy đóng gói gia vị

Máy đóng gói gia vị hoàn toàn tự động

Máy đóng gói gia vị hoàn toàn tự động đại diện cho đỉnh cao của công nghệ đóng gói. Các hệ thống đóng gói này được thiết kế để xử lý nhiều loại trọng lượng, từ ít nhất là 0-80 gram với số lượng lớn lên tới 3.000 gram mỗi túiTính linh hoạt của những chiếc máy này nằm ở khả năng chiết bột gia vị bằng cách đẩy chúng theo chiều ngang, chiều dọc hoặc theo một góc, phù hợp với nhiều hướng và kích thước túi khác nhau.

Các hoạt động chính chẳng hạn như định lượng, in ngày, tạo túi, chiết rót, niêm phong, cắt và đếm đều được tự động hóa, giúp giảm đáng kể nhu cầu can thiệp thủ công và giảm thiểu rủi ro sai sót.

Máy đóng gói gia vị bán tự động

Đối với các doanh nghiệp đang tìm kiếm sự cân bằng giữa tự động hóa và kiểm soát thủ công, máy đóng gói gia vị bán tự động cung cấp một giải pháp lý tưởng. Những máy này thường được thiết kế để đóng gói trọng lượng từ 1-10 kg và 5-50 kg. Trong khi các quy trình cốt lõi của việc cân và chiết rót được tự động hóa, người vận hành được yêu cầu đặt các túi đã chuẩn bị vào trạm chiết rót theo cách thủ công. Thiết lập này đặc biệt có lợi cho các hoạt động quy mô nhỏ hơn hoặc những hoạt động đòi hỏi mức độ tùy chỉnh cao hơn trong quy trình đóng gói của họ.

Thiết bị đóng gói bột chuyên dụng

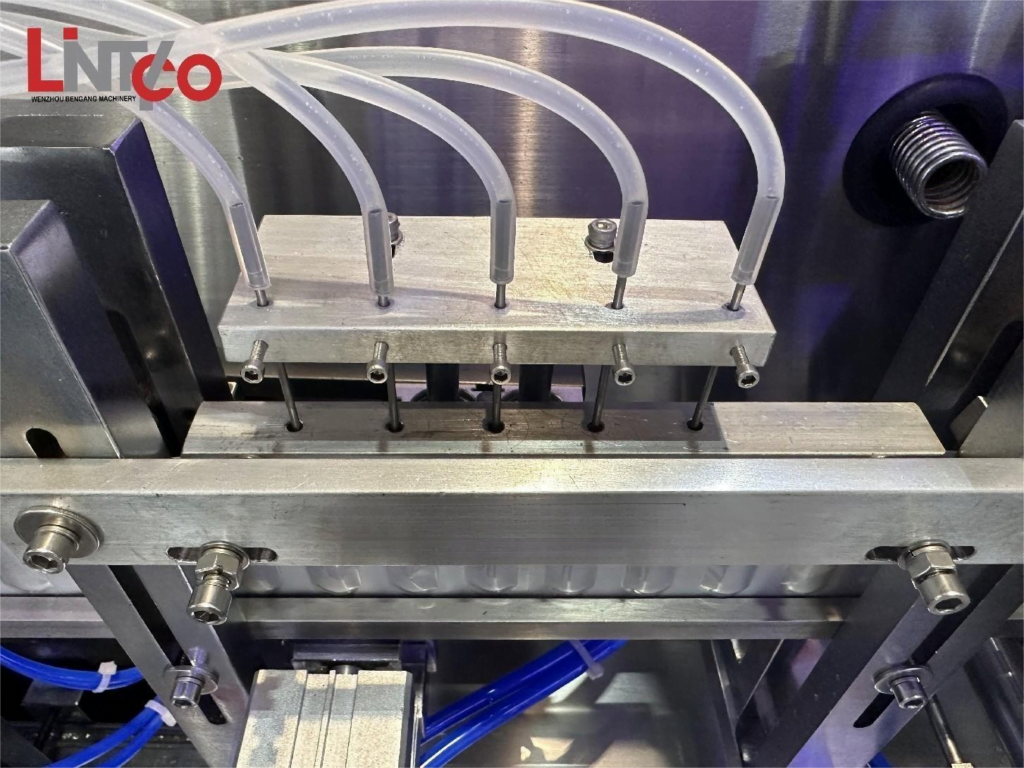

Ngoài các máy hoàn toàn tự động và bán tự động tiêu chuẩn, các thiết bị đóng gói bột chuyên dụng như băng tải trục vít và băng tải xả có thể được tích hợp để tăng cường chức năng. Các trục vít, thường được sử dụng trong các máy đóng gói bột, đóng vai trò quan trọng trong việc kiểm soát thể tích và đảm bảo độ mịn và độ mịn của bột gia vị. Các thành phần này có thể được tùy chỉnh dựa trên các yêu cầu cụ thể, cho phép độ chính xác và hiệu quả cao hơn trong quá trình đóng gói.

Thông số máy đóng gói bột gia vị tự động

| NGƯỜI MẪU | LTC420V | LTC520V | LTC620V | LTC720V |

| Công suất | 40 túi/phút | 35 túi/phút | 50 túi/phút | 45 túi/phút |

| Sự chính xác | ≤ ± 1,5% | ≤ ± 1,5% | ≤ ± 1,5% | ≤ ± 1,5% |

| kích thước túi | (Rộng)90-200mm (Dài)60-300mm | (R)110-260mm(D)80-350mm | (R)100-300mm(D)20-400mm | (R)140-350mm(D)20-450mm |

| chiều rộng phim | 420mm | 520mm | 620mm | 730mm |

| Túi loại | Đóng gói bằng màng, niêm phong trên, niêm phong dưới cùng và niêm phong phía sau bằng máy làm túi tự động. | |||

| Độ dày màng | 0,06-0,08mm, tốt nhất là 0,07-0,08mm | |||

| vật liệu đóng gói | vật liệu composite nhiệt., nhưBOPP/CPP, PET/AL/PE, v.v. | |||

| Tiêu thụ không khí | 0,8Mpa 0,5m3/phút | 0,8Mpa 0,3 m3/phút | 0,8Mpa 0,6m3/phút | 0,8Mpa 0,8m3/phút |

| Tổng số bột | 3.2KW | 2.545KW | 6.545KW | 6.545KW |

| Vôn | Bốn dây ba pha, 380V 50HZ | |||

| Máy nén khí | Không ít hơn 1,2 CBM (máy nén khí nên được cung cấp bởi người dùng) | |||

| Tổng chiều cao | 2,544 m | 3.761M | 3,76m | 3.955m |

Tính năng và lợi ích của máy đóng gói gia vị hiện đại

Kết cấu chắc chắn và độ bền

Máy đóng gói gia vị thường được chế tạo từ thép không gỉ 304 chất lượng cao, đảm bảo độ bền và dễ vệ sinh. Kết cấu chắc chắn này không chỉ kéo dài tuổi thọ của máy mà còn duy trì các tiêu chuẩn vệ sinh cần thiết cho việc đóng gói thực phẩm.

Hệ thống điều khiển thông minh

Được trang bị màn hình cảm ứng PLC và bộ điều khiển chip vi tính, máy đóng gói gia vị hiện đại cung cấp các hoạt động cực kỳ thông minh. Các hệ thống này cho phép kiểm soát chính xác tốc độ đóng gói, cài đặt nhiệt độ và ngôn ngữ vận hành, giúp máy thân thiện với người dùng và thích ứng với nhiều môi trường vận hành khác nhau.

Độ chính xác và hiệu quả được nâng cao

Hệ thống theo dõi mắt quang điện và băng tải màng servo cải thiện đáng kể độ chính xác và hiệu quả của quy trình đóng gói. Các công nghệ này đảm bảo rằng việc niêm phong và cắt diễn ra ở những vị trí chính xác, giảm thiểu chất thải và nâng cao chất lượng tổng thể của các loại gia vị đóng gói.

An toàn và tiện lợi

Các tính năng an toàn như nắp bảo vệ xung quanh các thiết bị cắt và niêm phong bảo vệ người vận hành khỏi các mối nguy hiểm tiềm ẩn. Ngoài ra, việc lắp bốn bánh xe ở đế máy giúp di chuyển dễ dàng, cho phép bố trí linh hoạt trong khu vực sản xuất.

Tùy chỉnh và khả năng mở rộng

Máy đóng gói gia vị cung cấp nhiều tùy chọn tùy chỉnh để đáp ứng nhu cầu kinh doanh cụ thể. Từ việc lựa chọn loại túi và kích thước đến tích hợp các thiết bị tùy chọn như máy in ngày và máy nạp chân không, những máy này có thể được tùy chỉnh để phù hợp với sự phát triển của doanh nghiệp bạn.

Ứng dụng của máy đóng gói gia vị

Tùy chọn đóng gói đa năng

Máy đóng gói gia vị có khả năng xử lý nhiều loại định dạng đóng gói, bao gồm lọ, túi, hộp và túi. Mỗi phương pháp đóng gói đều có những ưu điểm riêng về khả năng chống ẩm, ánh sáng và các yếu tố khác có thể ảnh hưởng đến chất lượng gia vị. Ví dụ, túi hút chân không kéo dài thời hạn sử dụng bằng cách loại bỏ không khí, trong khi lọ thủy tinh hoặc nhựa cung cấp khả năng hiển thị và dễ sử dụng.

Khả năng tương thích của nhiều loại gia vị

Những máy này tương thích với nhiều loại gia vị, bao gồm hạt tiêu đen, quế, thìa là Ai Cập, hạt nhục đậu khấu, gừng, đinh hương, nghệ tây, bạch đậu khấu, bột masala, v.v. Khả năng xử lý các loại bột có độ đặc khác nhau của chúng đảm bảo rằng mỗi loại gia vị được đóng gói với độ chính xác phù hợp, duy trì hương vị và hiệu lực của nó.

Nâng cao hiệu quả sản xuất

Thiết bị đóng gói gia vị tự động và bán tự động giúp tăng đáng kể hiệu quả sản xuất và sản lượng. Bằng cách hợp lý hóa quy trình đóng gói, các doanh nghiệp có thể đáp ứng nhu cầu cao hơn mà không ảnh hưởng đến chất lượng, cuối cùng thúc đẩy tăng trưởng và lợi nhuận.

Phần kết luận

Đầu tư vào một máy đóng gói gia vị hiện đại là một quyết định chiến lược có thể biến đổi kinh doanh gia vị. Với các tùy chọn từ hệ thống hoàn toàn tự động đến bán tự động, những máy này mang lại sự linh hoạt, hiệu quả và độ chính xác vô song. Các tính năng tiên tiến như hệ thống điều khiển thông minh, cấu trúc chắc chắn và các tùy chọn tùy chỉnh đảm bảo quy trình đóng gói của bạn vừa đáng tin cậy vừa có thể mở rộng.

Cho dù bạn là nhà sản xuất quy mô nhỏ hay nhà phân phối quy mô lớn, máy đóng gói gia vị phù hợp có thể nâng cao năng lực hoạt động, bảo vệ chất lượng sản phẩm và thúc đẩy doanh nghiệp của bạn đạt được thành công lớn hơn. Hợp tác với nhà sản xuất có uy tín giống Gói Lintyco đảm bảo rằng bạn không chỉ nhận được thiết bị chất lượng cao mà còn được hỗ trợ toàn diện và tùy chỉnh theo nhu cầu riêng của bạn. Nắm bắt tương lai của bao bì gia vị và đưa doanh nghiệp của bạn lên tầm cao mới.